7

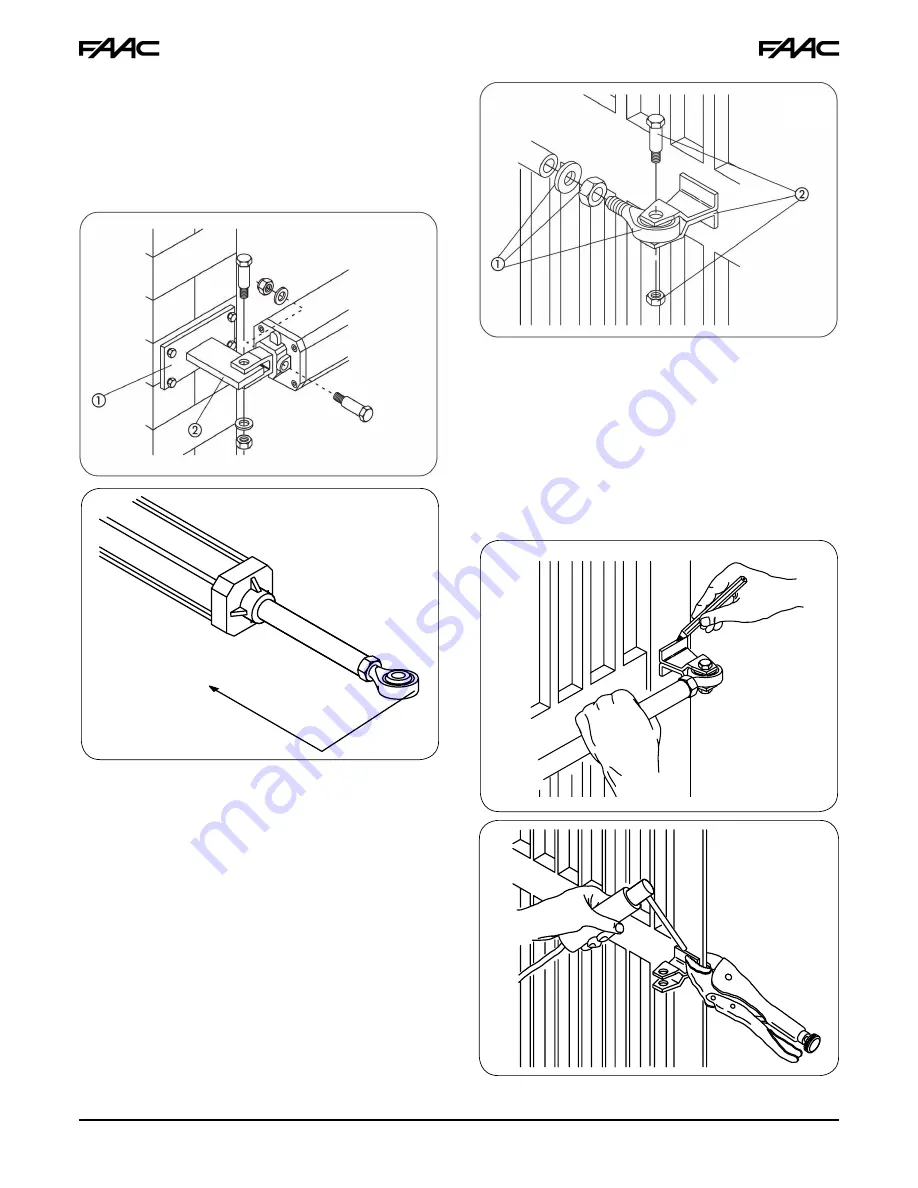

Figure 6

Figure 7

1/4 Inch

Figure 8

Figure 9

Figure 10

2.)

Secure the operator to the rear attachment with the

supplied screws (Fig. 6).

3.)

Screw, halfway down, the front attachment onto the

rod (Fig. 8, Ref.1). Tighten with the supplied nut.

4.)

Release the operator (

see Section 5

).

5.)

Fully extend the rod out to its stopping point, then push

it back approximately 1/4 inch (Fig. 7).

6.)

Relock the operator (

see Section 5.1

).

7.)

Fit the front bracket onto the rod (Fig. 8, Ref. 2)

8.)

Close the gate leaf and, while keeping the operator

perfectly horizontal, identify and mark the location of

the front bracket on the leaf (Fig. 9).

9.)

Temporarily fasten the front bracket to the leaf with two

weld spots (protect rod from welding slag).

If the gate structure does not permit the bracket

to be firmly fastened, modify the structure to

create a solid support base.

10.) Release the operator and manually check that the

gate can freely and completely open. Ensure that it

stops via the travel limit mechanical stops and that

leaf movement is good and frictionless.

11.) Temporarily release the operator from the bracket

and then permanently weld the bracket to the leaf.

Prevent welding slag from damaging the rod.

(Fig.10). If welding is not feasible, secure the front and

rear attachment plates with screws.

12.) Grease all securing pins of the attachments.

13.) Prepare the protective housing and fit it on the

operator as shown in Fig. 11. Fit the electric cable

strain relief (Fig. 12, Ref. 3).

14.) Re-lock the operator and make electrical connections

to the electronic control unit following the instructions

in the 455D section.