22

User Manual

ECO 200

Maintenance

F+D

Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

4. Maintenance

4.1 Ribbon- and Paper-Changing

Change the paper or transfer ribbon respectively as described under 2.5.

4.2 Cleaning of the Thermal Print Head

Depending on the application- as well as the environmental- conditions of the thermal printer, the print head

must be cleaned every 10 to 20 working hours.

1. Switch printer off.

2. Release the print head upper and rotate upwards

3. Wipe with a spirit dampened cloth several times smoothly over the printing

Notice

: Do not use any hard or sharp-edged objects.

4.3 Cleaning of the Feed Rollers

Above all paper and dust particles stick to the feed rollers, and have to be removed.

1. Switch printer off.

2. Release the print head upper and rotate upwards.

3. Clean feed roller with spirit and bobble free cloth.

4. After the rollers are dry, hinge print head device down and latch.

Notice

: Do not use acetone or any other solvents

.

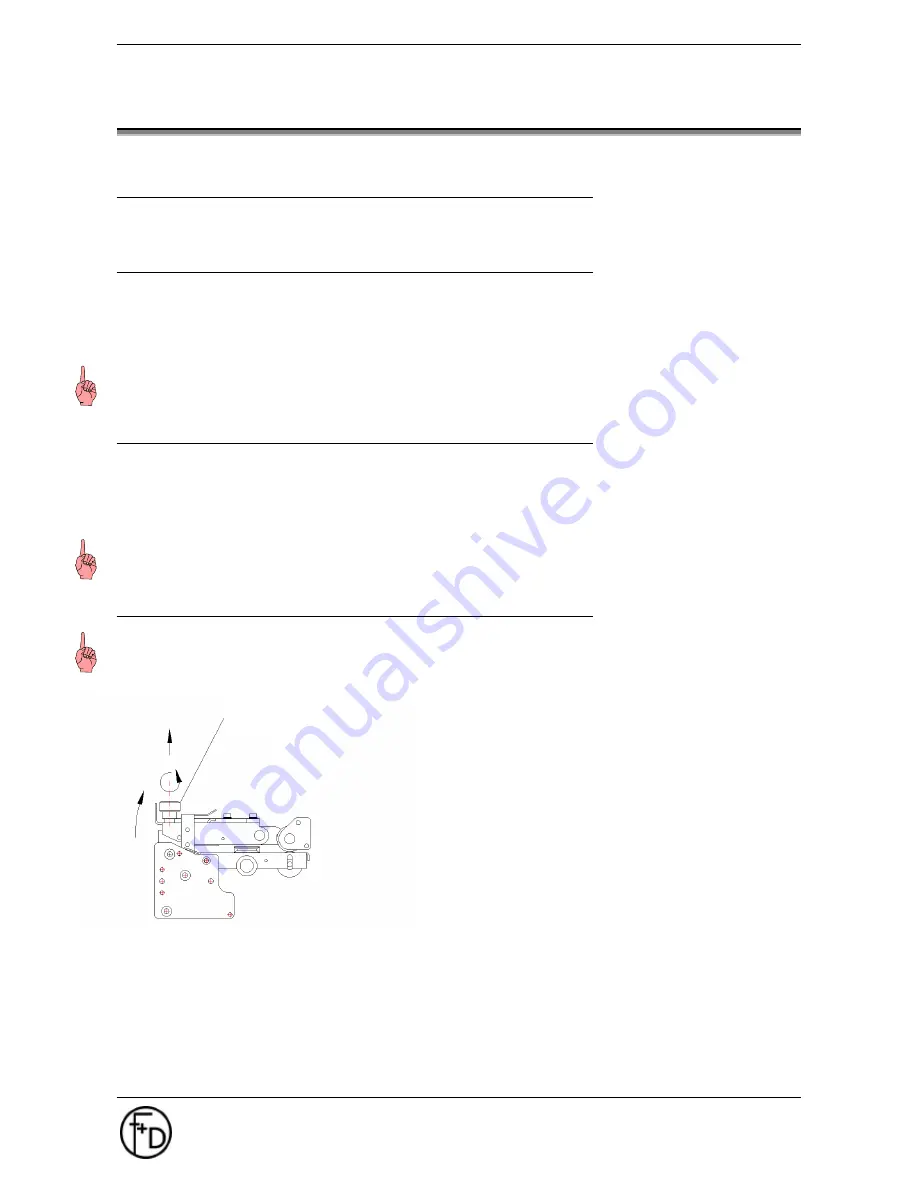

4.4 Changing of Thermal Print Head

Notice

: The thermal print head is a sensitive (mechanical, electronic and electro-static) component.

Do not

use any sharp-edged items, and take care that you are

not electro-statically

charged. Electrostatic charges

can damage the thermal print head, therefore it is absolutely necessary to execute a charge equalization in

advance..

1. Switch printer off and unplug mains plug.

2. Release the print head upper and rotate upwards.

3. Unlock knurled screw in the middle of the print head upper

and pull print head forwards.

4. Disconnect cables.

5. Fit the new thermal print head. The thermal print head is pre-

assembled onto an adapter and also pre-adjusted.

6. Connect cables to new thermal print head. Here, the correct

positioning of the connector has to be paid attention to.

Knurled screw