Maintenance

Change Hydraulic System

Filter and Fluid

Service Interval: After the first 250 hours

Every 500 hours/Yearly

(whichever comes

first) thereafter.

(Every 250 hours/Yearly

if using Mobil 1 15W50

thereafter)

Note:

Use only Exmark Part No. 109-4180 for

Summer use above 32°F (0°C) or P/N 1-523541 for

Winter use below 32°F (0°C) (Refer to

Transmission

section in Specifications for filter specifications).

1.

Stop engine, wait for all moving parts to stop, and

remove key or spark plug wire(s). Engage parking

brake.

2.

Remove the RH side guard.

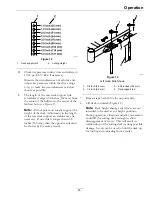

g271949

Figure 24

1.

RH side guard

3.

Place a catch pan under the hydro filter.

4.

Carefully clean area around filter. It is important

that no dirt or contamination enter hydraulic

system.

5.

Unscrew filter to remove and allow oil to drain

from reservoir.

Important:

Before reinstalling new filter, fill

it with Exmark Premium Hydro oil and apply

a thin coat of oil on the surface of the rubber

seal.

Turn filter clockwise until rubber seal contacts the

filter adapter, then tighten the filter an additional

2/3 to 3/4 turn.

6.

Fill reservoir as stated in

Check Hydraulic Oil

Level.

Exmark Premium Hydro Oil is recommended.

Refer to the chart for an acceptable alternative:

Hydro Oil

Service Interval

Exmark Premium Hydro

Oil (Preferred)

After first 250 hours

*Every 500 hours/Yearly

thereafter

Mobil 1 15W50

After first 250 hours

*Every 250 hours/Yearly

thereafter

*May need more often under severe conditions.

7.

Loosen filter 1/2 turn and allow a small amount

of oil to leak from the oil filter (this allows air to

be purged from the oil filter and supply hose from

the hydraulic reservoir). Turn filter clockwise

until rubber seal contacts the filter adapter. Then

tighten the filter an additional 2/3 to 3/4 turn.

8.

Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

CAUTION

Raising the mower for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support

or may malfunction allowing the unit to fall,

which could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands

or equivalent support.

9.

Start engine and move throttle control ahead to

full throttle position. Move motion control levers

inward (together) and move both levers forward

with equal pressure, and run for one minute. Shut

down the machine, allow the hydros to cool and

recheck oil level.

If either drive wheel does not rotate, one or both

of the charge pumps (located on the top of the

main pump as shown in Figure 25) may have lost

their “prime”. Refer to

Hydraulic System Air

Purge

section.

10.

Reinstall the RH side guard.

11.

Remove the jack stands.

36

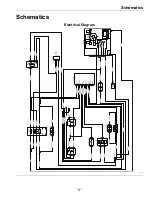

Содержание STARIS E Series

Страница 1: ...STARIS E SERIES For Serial Nos 406 294 345 Higher Part No 4504 758 Rev A ...

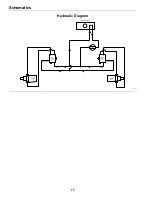

Страница 48: ...Schematics Hydraulic Diagram g270319 48 ...

Страница 50: ...Service Record Date Description of Work Done Service Done By 50 ...

Страница 51: ...51 ...