- 26 -

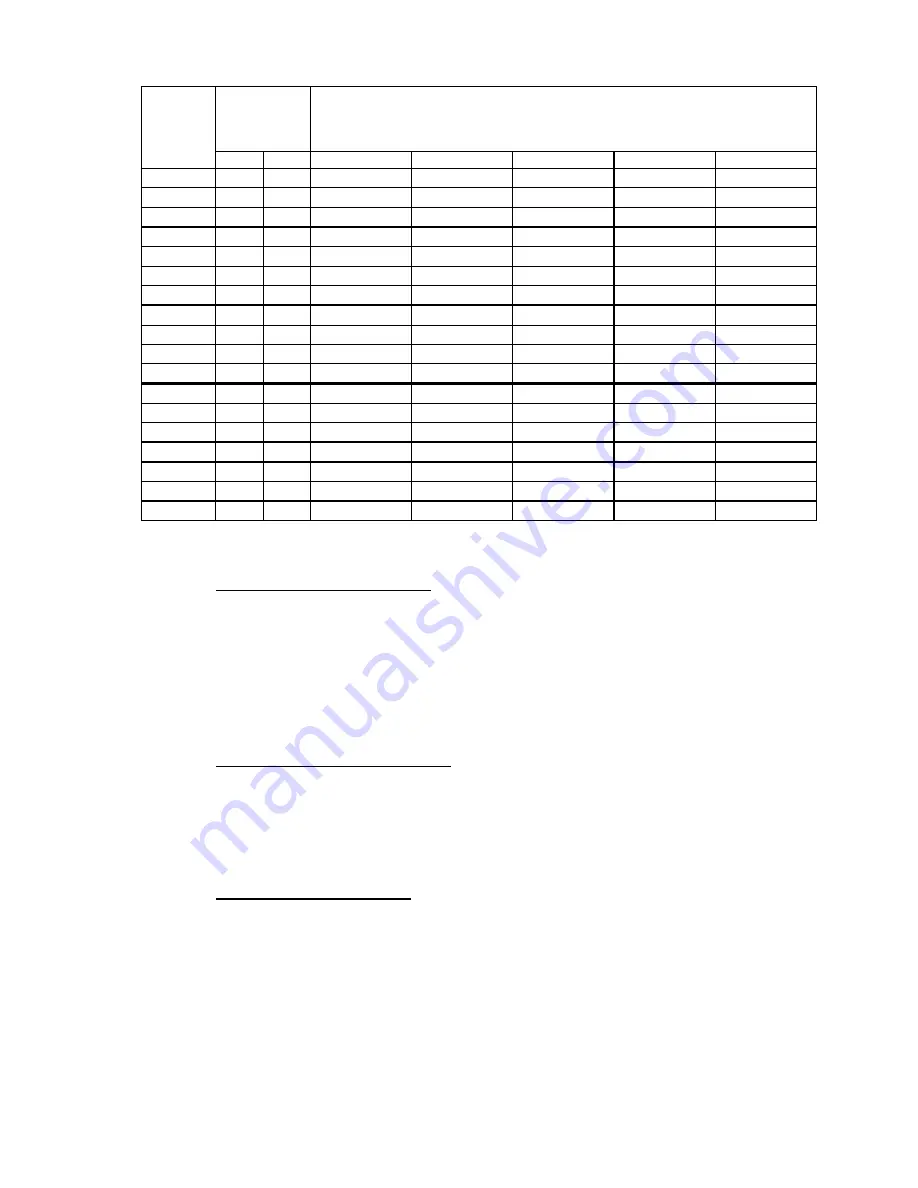

CUTTING HEIGHT ADJUSTMENT (1" to 4 1/4")

AXLE

POSITION

(FIG. 20)

# OF SPACERS

BELOW

CASTER

SUPPORT HUB

NUMBER OF 1/4" BLADE SPACERS

BELOW

SPINDLE

1/2"

3/16"

4 3 2 1 0

A

0

0

1" (2.5 cm)

1 1/4" (3.2 cm) 1 1/2" (3.5cm) 1 3/4" (4.4cm)

2" (5.0cm)

A

0

1

1 1/8" (2.9 cm) 1 3/8" (3.5 cm) 1 5/8" (4.1 cm) 1 7/8" (4.8 cm) 2 1/8" (5.4 cm)

A

1

0

1 3/8" (3.5 cm) 1 5/8" (4.1cm)

1 7/8" (4.8 cm) 2 1/8" (5.4 cm) 2 3/8" (6.0 cm)

B

0

1

1 3/8" (3.5 cm) 1 5/8" (4.1cm) 1 7/8" (4.8 cm) 2 1/8" (5.4 cm) 2 3/8" (6.0 cm)

B

1

0

1 5/8" (4.1 cm) 1 7/8" (4.8 cm) 2 1/8" (5.4 cm) 2 3/8" (6.0 cm) 2 5/8" (6.7 cm)

B

1

1

1 3/4" (4.4 cm)

2" (5.0 cm)

2 1/4" (5.7 cm) 2 1/2" (6.4 cm) 2 3/4" (7.0 cm)

B

2

0

2" (5.0 cm)

2 1/4" (5.7 cm) 2 1/2" (6.4 cm) 2 3/4" (7.0 cm)

3" (7.6 cm)

C

1

1

1 7/8" (4.8 cm) 2 1/8" (5.4 cm) 2 3/8" (6.0 cm) 2 5/8" (6.7 cm) 2 7/8" (7.3 cm)

C

2

0

2 1/8" (5.4 cm) 2 3/8" (6.0 cm) 2 5/8" (6.7 cm) 2 7/8" (7.3 cm) 3 1/8" (7.9 cm)

C

2

1

2 1/4" (5.7 cm) 2 1/2" (6.4 cm) 2 3/4" (7.0 cm)

3" (7.6 cm)

3 1/4" (8.3 cm)

C

3

0

2 1/2" (6.4 cm) 2 3/4" (7.0 cm)

3" (7.6 cm)

3 1/4" (8.3 cm) 3 1/2" (8.9 cm)

D

2

1

2 3/8" (6.0 cm) 2 5/8" (6.7 cm) 2 7/8" (7.3 cm) 3 1/8" (7.9 cm) 3 3/8" (8.6 cm)

D

3

0

2 1/2" (6.4 cm) 2 3/4" (7.0 cm)

3" (7.6 cm)

3 1/4" (8.3 cm) 3 1/2" (8.9 cm)

D

3

1

2 3/4" (7.0 cm)

3" (7.6 cm)

3 1/4" (8.3 cm) 3 1/2" (8.9 cm) 3 3/4" (9.5 cm)

D

4

0

3" (7.6 cm)

3 1/4" (8.3 cm) 3 1/2" (8.9 cm) 3 3/4" (9.5 cm)

4" (10.1 cm)

E

3

1

2 7/8" (7.3 cm) 3 1/8" (7.9 cm) 3 3/8" (8.6 cm) 3 5/8" (9.2 cm) 3 7/8" (9.8 cm)

E

4

0

3 1/8" (7.9 cm) 3 3/8" (8.6 cm) 3 5/8" (9.2 cm) 3 7/8" (9.8 cm) 4 1/8" (10.5cm)

E

4

1

3 1/4" (8.3 cm) 3 1/2" (8.9 cm) 3 3/4" (9.5 cm)

4" (10.1 cm)

4 1/4" (10.8cm)

IMPORTANT:

To achieve the highest quality of cut, the blades should be level

with the ground, or tipped slightly down at the front.

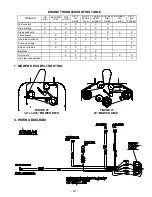

4.2.3

Transmission belt adjustment.

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) To tighten transmission belt, loosen the 3/8" nyloc nut on transmission belt

idler pulley. Slide bolt inward in slot and retighten nyloc nut.

c) When properly adjusted, the belt should have 1/2" (1.3 cm) of deflection with

three pounds of pressure on the belt midway between the transmission and

engine pulley.

4.2.4

Wheel drive belt pulley scrapers.

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) Be sure mud and grass scraper, on each side, is adjusted properly and centered

in the pulley grooves. The pointed part of the scraper should be centered and as

deep in the pulley groove as possible without rubbing at any point.

4.2.5

Engine to mower deck belt.

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) Check the adjustment of the lower blade drive linkage located between the

bellcrank on the engine deck and assist arm on the mower deck. Lengthen or

shorten the linkage. When properly adjusted, there should be 1/16" to 1/8" (2 –

3 mm) of clearance between bell-crank and transmission output shaft when belt

is engaged. Make sure the assist arm is against the rear assist arm stop on the

deck (See Figure 21). Push the lever down to the disengaged position. The

assist arm should contact the front assist arm stop on the deck. If it does not

contact, readjust so that the bellcrank is closer to the transmission output shaft.

Содержание Lazer ZXS

Страница 1: ...For Serial Nos 600 000 Higher Part No 103 9911 Rev A ...

Страница 40: ... 35 NOTES ...

Страница 41: ... 36 NOTES ...

Страница 42: ... 37 SERVICE RECORD Date Description of Work Done Service Done By ...