- 22 -

4.1.9

Check tire pressures.

Service Interval:

Pneumatic (air-filled) Drive Tires-

40 hrs.

Semi-pneumatic Caster Tires – No maintenance

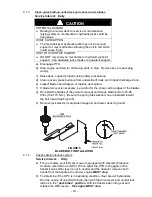

a) Stop engine and wait for all moving parts to stop. Remove spark plug wire(s).

Check air pressure in drive tires; recommended tire pressure is: 12 to 16 psi

(83-110 kPa).

b) Inflate tires to pressures stated above. Measure the circumference of each

drive tire. Adjust tire pressures within the above range to try to make tire

circumferences match as closely as possible.

4.1.10

Check grease level, input and output shaft bearing wear on Peerless

Transmission. (Replace gearbox grease yearly)

Service Interval: 160 hrs.

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) Place drive levers and neutral lock/park brake latches in neutral lock position.

c) Remove shifter lever from top of transmission.

d) Remove shifter plate from top of transmission and the two leads from the

neutral start switch.

e) Release the tension on the transmission belt.

f) Check for side play caused by bearing wear on the input and output shafts of

the transmission. Replace bearings if necessary.

g) Remove the six bolts that fasten the upper case to the lower case and

carefully remove the upper case half.

h) Check the grease level in the lower case. The grease level should be

approximately 1-1/2" to 1-3/4" (3.8 to 4.4 cm) from the gearbox bottom. If

necessary, fill to proper level with Peerless grease (Part No. 788067).

I) Reinstall upper case half and fasten in place with six bolts previously removed.

j) Reinstall all parts removed in Steps c and d. Install drive belt and adjust

tension as stated in Section 4.2.3.

4.1.11

Inspect belt wear.

Service Interval: 40 hrs.

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) Remove the mower deck belt shield to check mower blade drive belt

condition.

c) Look under engine deck to check the transmission drive belt condition.

d) Inspect wheel drive belt conditions.

e) Check all idler arms to be sure they pivot freely. Disassemble, clean and grease

pivot bushings if necessary.

4.1.12

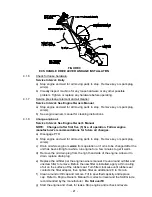

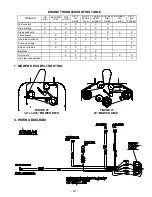

Lubrication:

Service Interval: Refer to Chart

a) Stop engine and wait for all moving parts to stop. Remove key or spark plug

wire(s).

b) Lubricate fittings with one to two pumps of SAE No. 2 multi-purpose gun grease

.

Refer to the following chart for fitting locations and lubrication schedule.

Содержание Lazer ZXS

Страница 1: ...For Serial Nos 600 000 Higher Part No 103 9911 Rev A ...

Страница 40: ... 35 NOTES ...

Страница 41: ... 36 NOTES ...

Страница 42: ... 37 SERVICE RECORD Date Description of Work Done Service Done By ...