Maintenance

Exmark Premium Hydro Oil is recommended.

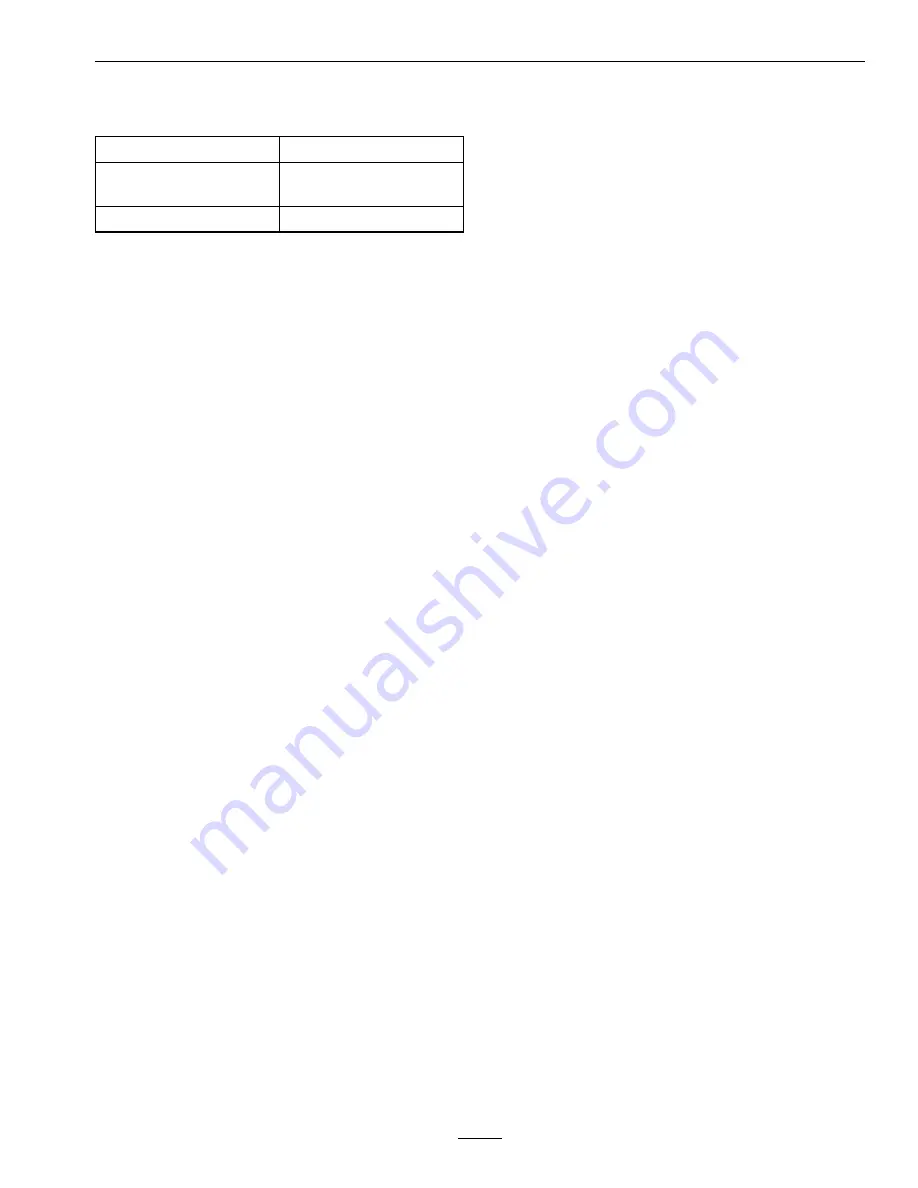

Refer to the chart for an acceptable alternative:

Hydro Oil

Change Interval

Exmark Premium Hydro

Oil (Preferred)

500 Hours

Mobil 1 15W50

250 Hours

10. Remove the catch pan and properly dispose of

hydro oil and filter according to local codes.

11. Re-install the pump drive belt.

12. Start engine and move throttle control ahead to

full throttle position. Move the speed control

levers to the full speed and run for one minute.

Shut down the machine, allow the hydros to cool

and recheck oil level.

13. Remove the jack stands.

Note:

Do Not change the hydraulic system oil

(except for what can be drained when changing filter),

unless it is felt the oil has been contaminated or been

extremely hot.

Changing oil unnecessarily could damage hydraulic

system by introducing contaminants into the system.

Wheel Hub - Slotted Nut

Torque Specification

Service Interval: After the first 100 hours

Every 500 hours thereafter

Torque the slotted nut to 211-260 ft-lb (286-352

N-m).

Note:

Do Not use anti-seize on wheel hub.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

•

ROPS spring pin housing.

•

Hydro pump control arm, linkage bolt, and

attachment bolt.

•

Hydro cooling fan screw.

•

Hydro park brake cable anchor mounting bolt

•

Sheave and clutch retaining bolt in the end of

engine crankshaft.

Thread locking adhesives are required for some

hardware on engines — see the Engine manual.

Copper-Based Anti-seize

Copper-based anti-seize is used in the following

location:

On threads of Blade Bolts. See

Check Mower

Blades

section.

Dielectric Grease

Dielectric grease is used on all blade type electrical

connections to prevent corrosion and loss of contact.

LPG Regulator

No adjustments necessary. If the engine is not

running properly, contact an Authorized Service

Dealer

41

Содержание Laser Z LZS29PKA604

Страница 1: ...LAZER Z PROPANE For Serial Nos 920 000 Higher Part No 4500 720 Rev A ...

Страница 14: ...Safety 109 9875 116 0157 1 See Operator s Manual 116 0205 116 0211 116 0752 1 Latch 2 Unlatch 14 ...

Страница 16: ...Safety 109 9906 16 ...

Страница 57: ...Schematics Hydraulic Diagram 57 ...

Страница 59: ...Notes 59 ...

Страница 60: ...Notes 60 ...

Страница 61: ...Service Record Date Description of Work Done Service Done By 61 ...

Страница 62: ...62 ...