14

Setup Guide

Getting Started

CONNECT YOUR UNIT TO THE SHIELDING GAS.

Always wear safety glasses when changing a cylinder. Before in-

stalling any cylinder, stand to the site of the valve, away from the

discharge, and quickly open the cylinder to give it a quick blast. This

will dislodge any dirt or particles stuck in the valve or the connection

seat. This will help reduce the chance of dirt particles making its way

into the solenoid valve, causing sticking issues later on.

Connecting your cylinder will require a cylinder wrench(1

1/16”)

to

connect the regulator to the cylinder (North American Cylinders with

What Shielding Gas Should Be Used?

Selecting shielding gas for MIG is straightforward. For all metals,

whether using in AC or DC, use 100% Argon. Never use a gas mix

mixed with CO

2

. CO

2

will rapidly consume the tungsten and intro-

duce porosity into the weld even at low concentrations.

With that said, if you are welding at or near the maximum capability

of the unit, you may also wish to use an Argon/Helium mix. This

will increase the overall heat going into the weld. No more than

25% Helium mix should be used with this unit, or Arc starting effi-

ciency will be reduced (hard to start arc). Arc stability will also be

affected at higher percentages. Helium is expensive and the cost

versus benefit of adding it must be weighed carefully as a cylinder or

two of high percentage Helium may approach the cost difference of

upgrading to a larger unit! If a high Helium content is used, expect

some trade

-

offs. Arc starting may be improved slightly by readjust-

ing the point gap.

There are a few new gas mixes (blends) on the market with promise,

but as of publication they have not been thoroughly evaluated for

use with this welder. Exercise caution when using a new mixture

(often marketed with Nitrogen or Hydrogen) as the application is very

specific. Pure 100% Argon is the most economical and best for

nearly every application, and having multiple gases should not be a

concern for even the most advanced user.

BE AWARE:

It is increasingly common for users to get cylinders of

“

bad gas,

”

creating mysterious and difficult to identify issues

. An

Argon cylinder is the same type of cylinder as an Argon/CO

2

cylinder

used for MIG and sometimes times can get mixed in and relabeled

as pure argon. Another increasingly common issue is that a gas mix

cylinder gets refilled with Argon with residual Ar/CO

2

mix without

using proper purging techniques. Usually this occurs in

“

batches

”

and complete lots of cylinders can be affected. Sometimes swapping

with another cylinder from the same supplier will not correct the

problem. Also it has been found that a customer to specify

“

Argon

”

and receive a cylinder marked as Argon/CO

2

mix. Always check your

cylinder label below the cap area for proper labeling before accept-

ing the cylinder.

a 580 CGA valve). If you do not have a cylinder wrench, an adjusta-

ble type wrench will work, but make sure it is properly adjusted to

prevent rounding of the fitting shoulders. Do not use pliers, or a

serrated jaw wrench such as a pipe wrench or basin wrench to tight-

en the fitting. The design of the fitting means that no thread sealing

tape or compound needs to be used.

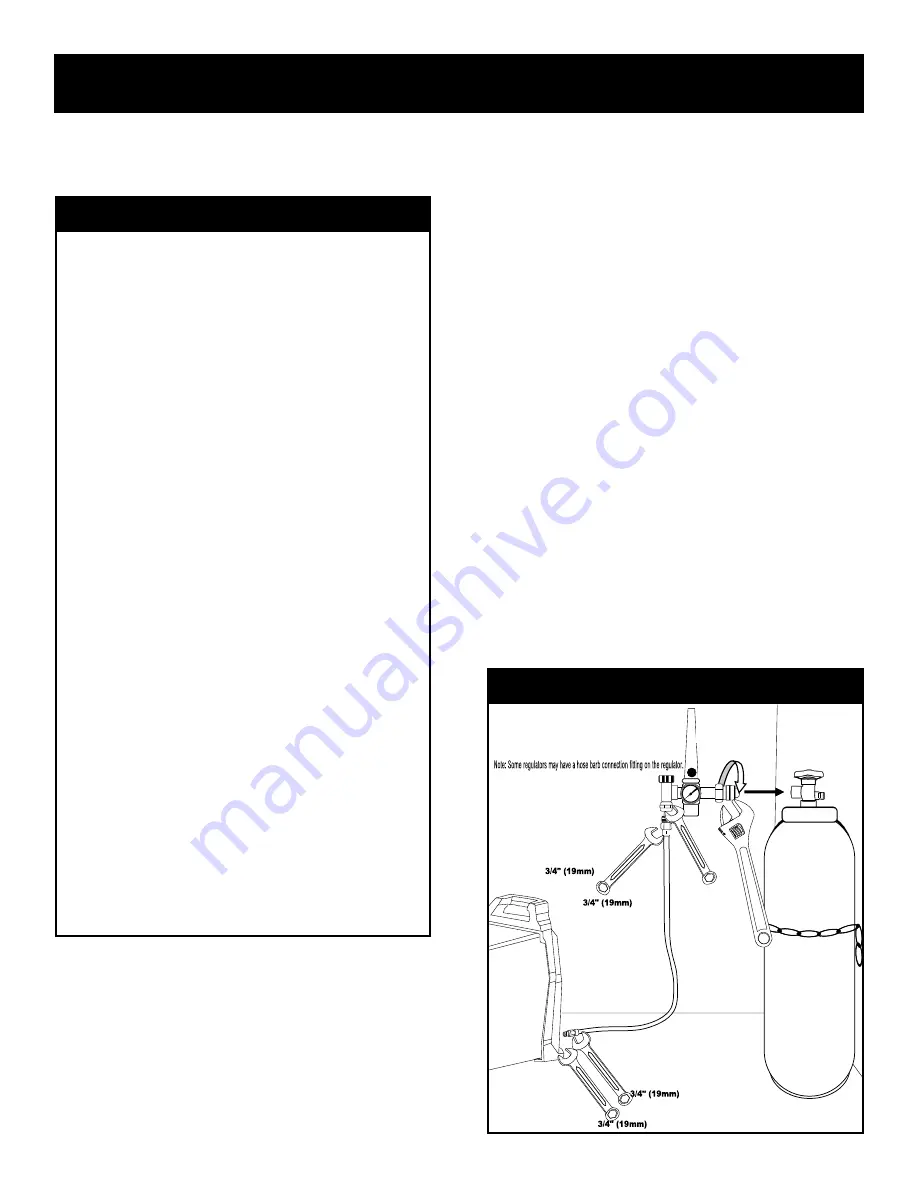

Connect the regulator tubing to the regulator. The regulator may

have either a hose barb connection, or a threaded connection. If the

regulator supplied has a hose barb, make sure the hose barb fitting is

tight on the regulator. Tighten with a

3/4”

(19mm) wrench. If it is a

threaded connection, use two

3/4”

(19mm) wrenches to hold both

the regulator and the tubing connection at the same time. Hold

counter pressure on the regulator connector while tightening the

hose fitting to prevent damage to the regulator and to ensure maxi-

mum sealing. After connecting the tubing to the regulator, connect

the other end of the tubing to the

5/8”

CGA fitting on the unit. Hold

the fitting on the unit with one

3/4”

(19mm) wrench firmly while

tightening the hose fitting with another

3/4”(19

mm) wrench. Im-

portant! Do not use thread tape or pipe sealant on any cylinder, regu-

lator or unit connection. The residue and debris may get into the gas

solenoid and cause operational issues.

CAUTION!

Do not tighten the rear unit connection without holding

the female fitting on the unit with a wrench, or damage may occur to

the bezel as the fitting may turn in the plastic housing while the hose

fitting is being turned..

Connect Regulator To Cylinder And Unit.

Содержание PowerTIG 200 EXT

Страница 38: ...38...