2

NOTE

The words “Shall” or Must” indicate a requirement which is

essential to satisfactory and safe product performance.

The words “Should” or “May” indicate a recommendation

or advice which is not essential and not required but which

may be useful or helpful.

WARRANTY AND RESPONSIBILITIES

It is the sole responsibility of the home owner to make cer-

tain that the gas furnace has been correctly set up and con-

verted to the proper fuel (Propane or Nat. gas) and ad-

justed to operate properly.

Evcon Industries, Inc. warrants the furnace to be free from

defects in material or workmanship for a period of one year

(see warranty certificate packed with the furnace).

However, Evcon Industries, Inc. will not be responsible for

any repair costs to correct problems due to improper set---

up, improper installation, furnace adjustments, improper

operating procedure by the user, etc.

Some specific examples of service calls which cannot be

included in warranty payments are:

CONVERTING THE FURNACE TO USE ANOTHER

TYPE OF GAS.

1. Correcting faulty duct work in the home.

2. Correcting wiring problems in the electrical circuit to the

furnace.

3. Resetting circuit breakers or other switches.

4. Adjusting the burner air shutter or service calls made to

correct problems caused by improper air adjustment.

5. Correcting problems due to improper gas supply pres-

sure to the furnace.

6. Instructional training on how to light and operate fur-

nace.

7. Furnace problems caused by installation of air condi-

tioner, heat pump, or other air quality device which is not

approved.

8. Problems due to improper installation of the furnace flue

assembly (roof jack).

You should establish a

firm

understanding of these re-

sponsibilities with your manufactured housing dealer, ser-

vice company or gas supplier so there will be no misunder-

standing at a later time.

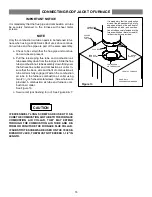

Gas Supply

CAUTION

Before placing furnace in service, it must be

checked to make sure it is equipped for the type of

gas being used. The burner flame must also be ob-

served and adjusted if necessary. Failure to ob-

serve this caution may result in unsafe operation,

explosion, and/or fire or asphyxiation. See follow-

ing sections “Gas Supply” and “Combustion Air”.

The gas supply to your home will either be Nat. Gas or Pro-

pane gas (bottle gas). Your furnace will be factory equipped

to operate on only one of these two different gases.

A small metal tag secured to the furnace just under the gas

valve will specify the type of gas your furnace is equipped

to use.

If the gas is different from that specified on the metal tag,

the furnace can be converted by following the instructions

on the furnace name plate. Parts for conversion are con-

tained in the small cloth bag attached to the gas valve. Be

sure the proper size orifice is used, as specified on the fur-

nace name plate.

CAUTION

The furnace must be converted by a qualified tech-

nician. Improper conversion can cause unsafe op-

eration, explosion, and/or fire or asphyxiation.

For Nat. gas operation the furnace is designed for 7” W.C.

inlet pressure. Pressure is reduced to 3---1/2” W.C. by the

pressure regulator in the gas valve.

For Propane gas, pressure at the gas valve must be 11”

W.C. When the gas valve is properly converted to Propane

gas, the pressure regulator in the gas valve is blocked

open, and the pressure is regulated at 11” W.C. by the reg-

ulator on the Propane gas tank. Consequently, the regula-

tor at the Propane tank may require adjustment.

CAUTION

If the gas input to the furnace is too great because

of excessive gas pressure, wrong size orifice, high

altitude, etc., the burner flame will be sooty and

may produce carbon monoxide, which could result

in unsafe operation, explosion, and/or fire or as-

phyxiation.

Never remove or block open the burner observa-

tion cover on the furnace. To do so may cause car-

bon monoxide to be drawn into the living space and

may cause asphyxiation.

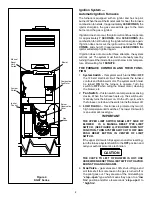

OBSERVING BURNER OPERATION

1. Observe burner to make sure it ignites. Observe color

of flame. On Nat. gas the flame will burn blue with ap-

preciably yellow tips. On Propane gas a yellow flame

may be expected. If flame is not the proper color call a

qualified serviceman for service.

See Figures 2 and 3.

2. Let furnace heat until blower cycles on.

3. Turn thermostat down.

4. Observe burner to make sure it shuts off.

5. Let the furnace cool and blower cycle off.

Содержание DGAM Series

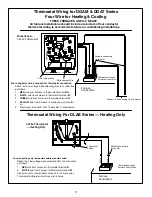

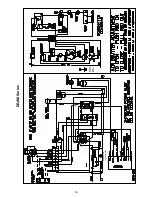

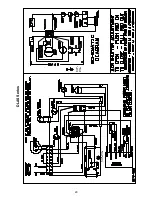

Страница 19: ...18 WIRING DIAGRAMS DGAT Series Ground Screw To Earth Ground Ground Screw to Earth Ground...

Страница 20: ...19 DGAM Series Ground Screw To Earth Ground Ground Screw to Earth Ground...

Страница 21: ...20 DLAS Series Ground Screw To Earth Ground Ground Screw to Earth Ground...

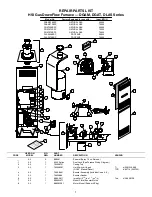

Страница 24: ...23...