5

Technical data

Transport length:

3.30 m

Width:

1.35 m

Transport height:

1.80 m

Working height:

1.80 -2.10 m

Sifter surface:

1.40 x0.75 m

Weight

950 kg

Approx. performance:

7-9 t/h

Arrangement of sifting:

3 sieves arranged one above the other

Electro motor:

1x 1.1kW FU Controlled 230 volt

1x 0.37kW, 380 volt (sifter cleaning)

Noise reduction:

measured 71 dB (A) at the ear of the operating person

while sorting.

3.

Start-up and operation

This sorter is a machine wit three screens and therefore suitable for sorting into four sizes, whereas

two sizes can be sorted on an added sorting table. Oversizes and triplets will be lead out of the ma-

chine on the left and hand or right hand side out of the machine.

Before start up the accordance of the power supply with the voltage of the motors has to be

checked.

In order to reach an optimal sorting accuracy the machine is equipped with a continuous speed con-

trol (frequency control) and additional interval drive which means the rotation speed of the crank

shaft changes continuously between 0 and ful rotation speed. This low-maintenance interval drive is

electronically controlled via a timed relay in the control cabinet. The interval of the pause can be

slightly changed by turning the knurl switch on the outside of the control cabinet accordingly. The

relation pause - operation time should lie by about 1:2. Additionally the interval operation can be

switched "on" or "off" via a second switch.

The screen cleaning slide is lead via the middle belt. A good tension of the belt has to be ensured.

The screen cleaning bars should be adjusted until they hit briefly under the screen when in their

highest position.

For changing of the screen the screen cleaning slide has to be driven backwards (to the main bear-

ing). The screens can be taken out on the side after the bolts have been disengaged.

Apart from this main bearing all bearings are maintenance-free. These should be greased app. every

100 hours of operation.

For a long life and faultless operation the machine should be kept as clean as possible.

If during activation of the machine on the left hand side of the control cabinet the red indicator lamp

"rotation direction wrong" illuminates, the rotating field of the power connection is wrong. The ma-

chine does not start up. In order to change the rotating field two phases in the connecting plug

( phase inverter) have to be swapped.

In order to switch on the screen cleaning slide the switch "screen cleaning" has to be switched to

"I".

Содержание EURO-Sorter JKS 144/4S

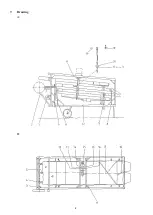

Страница 8: ...8 7 Drawing A B ...

Страница 10: ...10 9 Electric schematic diagram ...

Страница 11: ...11 ...

Страница 12: ...12 ...

Страница 13: ...13 ...

Страница 14: ...14 ...