Kuvamateriaali on havainnollistava

Pidätämme oikeuden muutoksiin

RDT-07-0121

59

®

NORD

fire

|

FDMB

12. Inspection, testing

12.1 The appliance is constructed and preset by the manufacturer, its operation is dependent

on proper installation and adjustment.

13. Logistic terms

13.1 Dampers are transported by box freight vehicles without direct weather impact, there must not

occur any sharp shocks and ambient temperature must not 40°C. Dampers must be

protected against mechanic damages when transported and manipulated.

During transportation, the damper blade must be in the "CLOSED" position.

13.2 Dampers are stored indoor in environment without any aggressive vapours, gases or dust.

Indoort emperature must be in the range from -30°C to +40°C and maximum relative humidity

95 %

(avoid condensation on the damper body). Dampers must be protected against mechanic

damages when transported and manipulated.

14. Assembly

14.1 All effective safety standards and directives must be observed during fire damper assembly.

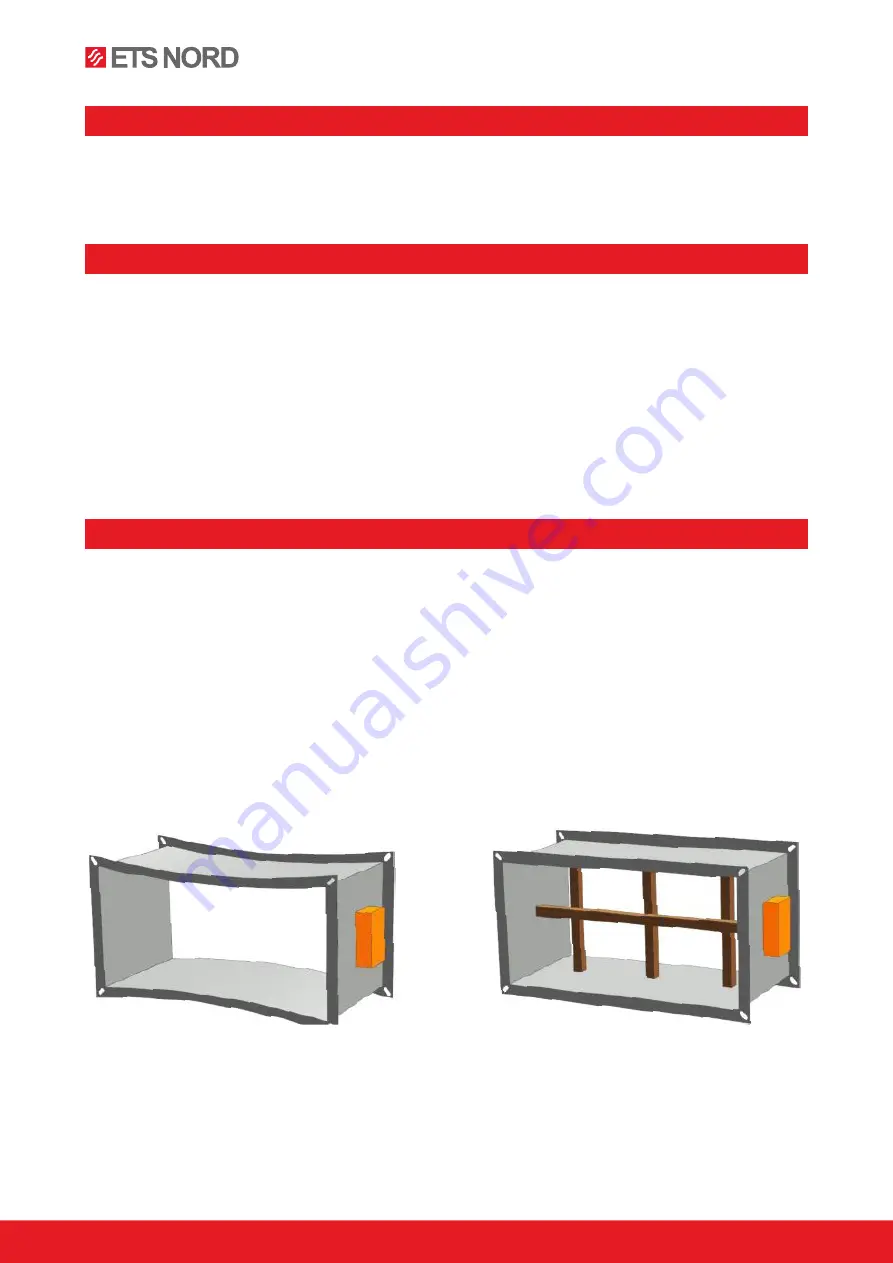

14.2 The damper body should not be deformed in the course of bricking in. Once the damper is built

in, its blade should not grind on the damper body during opening or closing.

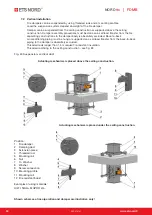

Fig. 65 Embedding/ fixing the damper

Protecting the damper against buckling,

above all when there are big sizes of the fire dampers!

WRONG! Brace with wooden blocks

14.3 To ensure reliable fire damper function it is necessary to avoid blocking the closing mechanism

and contact surfaces with collected dust, fibre and sticky materials and solvents.

IX. Inspection, testing

IX. Transportation and storage

IX. Assembly, attendance, maintenance and revisions