Type / No.

Rev.

Date

Page

Total pages

EW082.695_en

5

02 August 2010

22

28

EsiWelma

s.r.l.

4.9

Sensor operation check

After the sensor is calibrated it is necessary to make sure it is operating correctly. For this

purpose, it is necessary to scrupulously perform the following in order to prevent incorrect

test actions that could cause permanent damage to the sensing element.

We recommend using the TUL40 calibration and test case for this purpose. It consists of:

•

One cylinder (12 l) of gas calibrated at 50% of the L.E.L. of the detected gas (e.g.:

Methane)

•

One pressure valve and flow regulator (the latter is optional)

•

One flow chamber that will fit properly around the sensing element

•

One hose between cylinder and adapter (

∼

2 m long)

In any case, follow the checklist below to carry out the test:

1.

for the test, use the same type of gas that the sensors will be detecting

2.

the test cylinder must be calibrated with the concentration kept below the maximum

levels of the detector measuring range

3.

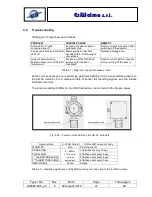

the test gas flow must spread to the sensing

element or reach it at a low flow rate (max 0.5

litres / minute).

For

this

purpose,

use

a

specific

flow

measurement chamber that fits properly around

the sensing element (Fig. 4.26), and if necessary

a field flow meter

4.

a few dozen seconds may pass from the time the

test gas is released to the moment the detector

senses its presence and precisely measures its

concentration. This “delay” is caused by the

action of the sintered filter located at the bottom

end of the detector to protect the sensing

element. The same delay may occur from the

moment test gas release is terminated until the

moment the detector no longer senses its

presence.

5.

the sensor must activate the alarm during the test: make sure the alarm is activated

by controlling the LED status on the sensing element; this must be flashing as shown

in table 4.2, according to the concentration level detected by the TUS40-20 terminal

unit in the monitoring mode described above.

WARNING

Repeated use of inappropriate or high concentrations of test gases causes

permanent poisoning of the sensing element with a subsequent deterioration in

performance, or permanent abnormality, of the detector.

Test gas inlet

Test gas outlet

F

lo

w

c

h

a

m

b

e

r

Fig. 4.26 – Flow chamber