12

paste collected during the floating operation. Increase the blade pitch up to 10mm for the first

finishing operation and then continue to increase the pitch on the following finishing operations.

Continue the finishing passes until you obtained the desired finished floor surface. The time

required between each finishing pass is dependent on the weather conditions, cement and water

content of the concrete. If some areas of the concrete set harden too fast, you may apply a small

amount of water with a brush to help achieve a finish. Be careful when running the concrete

finisher on areas where water has been applied because the machine will tend to skate away. Be

sure to maintain control of the concrete finisher at all times.

Pitch Adjustment

The pitch control knob or the optional blade pitch lever is in easy reach of the operator. The pitch

adjustment has a limited pitch variation. Rotate the pitch control knob clockwise to tilt the blades

and counterclockwise to flatten the angle of the blades. Adjustment is based on the desired

performance for the specific job application. With the blade pitch lever, blade pitch can be adjusted

by depressing the spring-loaded button in the adjustment lever and moving the lever to the desired

pitch.

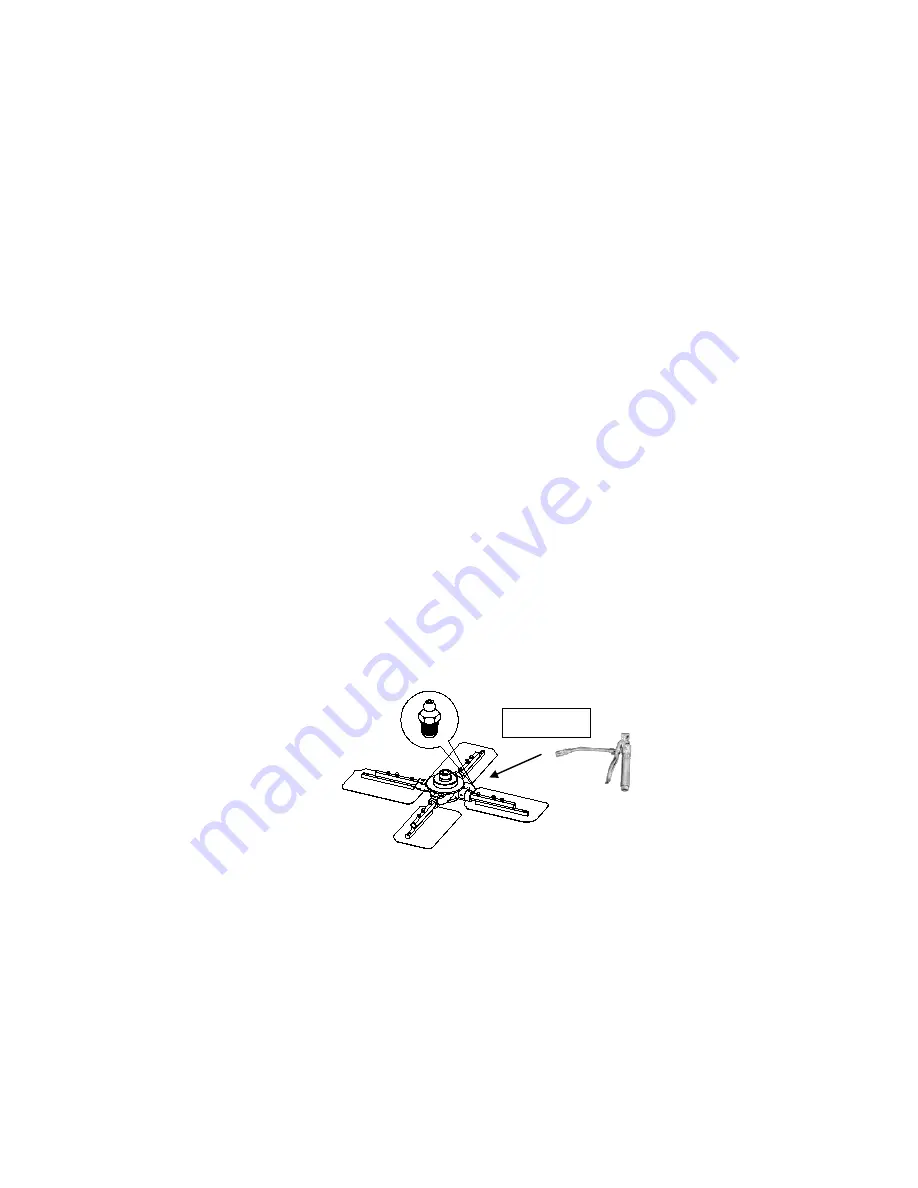

Spider Plate

By experience, we know that 2 major problems with the concrete finisher’s arms are lack of

lubrication and bent arms due to the machine being dropped. Greasing should be carried out on a

weekly basis using the grease nipple provided (Figure 3). If an arm becomes jammed, this is

probably due to the arm being bent and will require replacement.

Figure 3 - Lubrication

GREASE

Содержание EWT120

Страница 1: ...Operator s Manual Concrete Finishers Range Concrete Finisher EWT90 EWT120 Manual Version 1...

Страница 2: ...2 Concrete Finisher Proposition Warning...

Страница 19: ...Notes...