12

SECTION 3

MAINTENANCE

3.1 GENERAL

Before any maintenance is attempted on this

torch, make sure the power switch on the con-

sole is in the "OFF" position and the primary

input is deenergized.

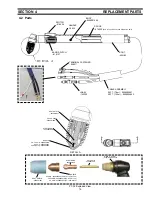

3.2 INSPECTION AND CLEANING OF

CONSUMABLES

A. Disassemble the front end of the PT-32 as

follows:

1.

Position torch head in a downward direction

(refer to Figure 2-1) and remove the shield.

The nozzle will drop from the head and

remain in the shield. Unscrew the electrode

to remove it and the valve pin. Remove these

components and inspect for wear. The nozzle

and electrode will generally wear at the same

rate. For best performance, replace together.

2.

Nozzle: Replace if the orifice is clogged, nicked,

or out-of-round.

3.

Electrode:

When replacing the nozzle, always

inspect the electrode for wear. If more than

.06" of electrode Hafnium has eroded, replace

the electrode. If the electrode is used beyond

this recommended wear limit, damage to the

torch and power source may occur. Nozzle life

is also greatly reduced when using the elec-

trode below the recommended limit. Refer to

Figure 3-1.

4.

Shield: The face of the shield will gradually

erode from the heat and molten metal spray.

Replace the shield if more than 1/8 inch (3.2

mm) has eroded from the face. Refer to Fig-

ure 3-1.

5.

O-ring: Lubricate as per Figure 3-1. Replace

if cut or worn. Air leaking past this seal will

reduce cutting performance.

B. To replace the above front end components,

refer to Figure 2-1.

HEAT SHIELD

Figure 3-1. O-ring, Electrode, and Shield Maintenance

LUBRICANT (P/N 17672) CAN BE

APPLIED TO O-RING OR HEAT SHIELD.

THE HEAT SHIELD FACE WILL

GRADUALLY ERODE WITH USE.

SEE PARAGRAPH 3.2.A.4.

O-RING

REPLACE ELECTRODE BEFORE PITTING

BECOMES DEEPER THAN .06 INCH (1.5 MM)

NEW

Replace when eroded beyond

.06"(1.5mm) Depth.

WORN