FLANGE ALIGNMENT TOOLS

OPERATOR INSTRUCTION MANUAL

PAGE 13

•

On return from each job and before allocation against subsequent work the

completeness of the Equalizer FA4TM kit must be established and

items examined to ensure that they are serviceable

•

Any missing or damaged items are to be replaced as soon as possible and prior to the

tool being used again

•

Store the FA4TM in a cool dry place and ensure all machined surfaces

are greased

•

Return all items to carry case when not in use

•

Ensure rollers, pins and wing remain grit free and that the rollers rotate freely

•

Grease all moving parts regularly:

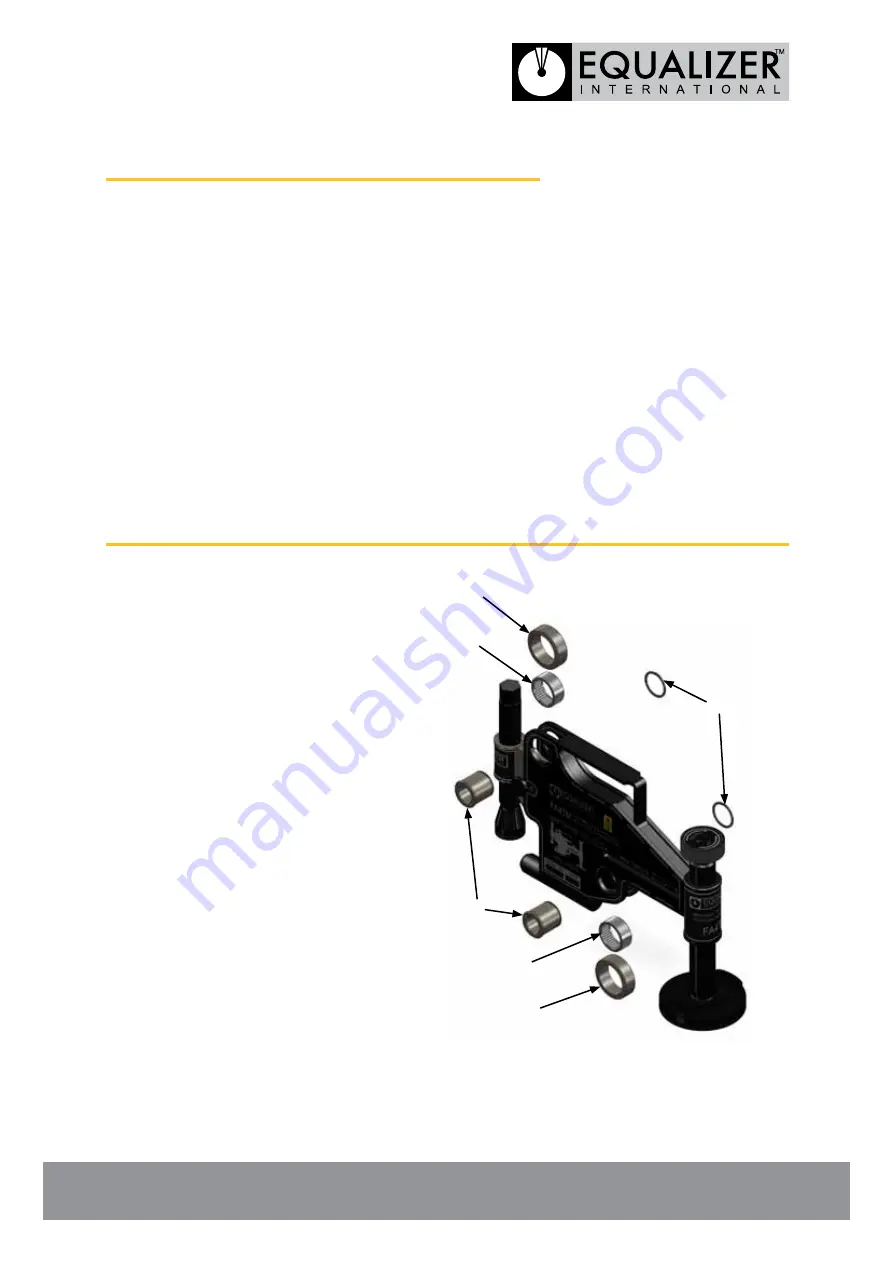

5.4 EXAMINATION, MAINTENANCE AND STORAGE

1.

Secure the tool upright on a

bench.

2.

Using a small flat screw driver, lever

out the end of the spiral clips and

then rotate anti-clockwise and

remove.

3.

Slide the roller shafts out in order to

remove the rollers and bearings for

examination.

4.

Inspect the roller shafts, rollers and

bearings for damage. If there is no

damage present then they can be

cleaned, greased and re-assembled

by reversing steps 1-4

Recommended grease -

Hi-load bearing grease

e.g. Rocol Saphire hi-load

SPIRAL

CLIPS

NEEDLE

BEARING

ROLLER

NEEDLE

BEARING

ROLLER

ROLLER

SHAFTS