Epso

4

.

T

A.

H

Most

The

Fo

Befo

B.

Q

Depe

and

wors

Coun

1)

1

s

2)

m

3)

Us

4)

us

5)

Us

6)

re

7)

He

Note

RIP

Se

●

Plat

●

Hea

●

Rol

●

Ten

●

Me

n

Engineering

TROUBLE

SH

Head

Alignm

t

of

grainine

head

Alignm

or

head

Align

ore

head

align

Quality

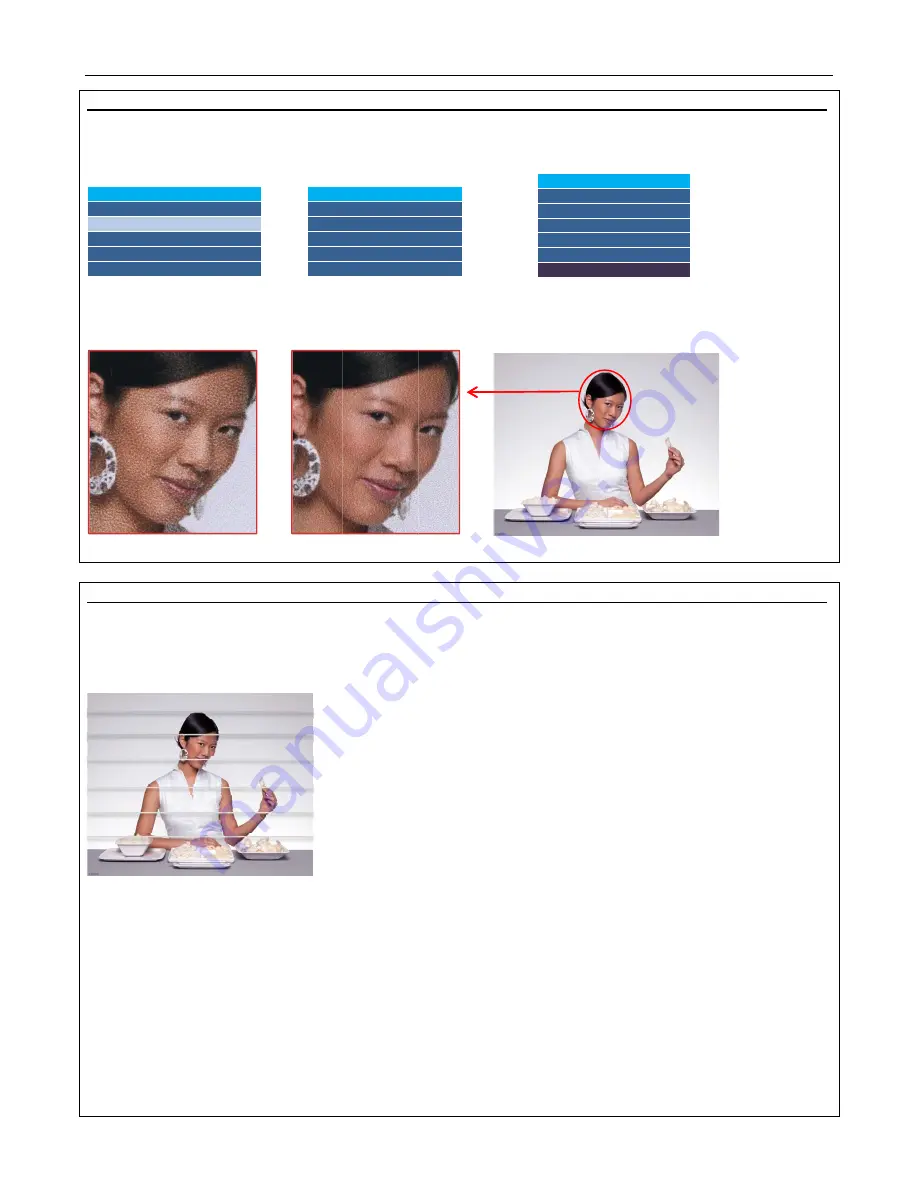

Band

ending

on

th

causing

head

se

:

CR

block

ntermeasure

t

of

all,

check

ake

sure

the

se

the

best

m

se

the

correc

se

correct

he

educe

the

ink

ead

moveme

e

:

for

quality

ettings

:

ten

Gap

(1,5,

2,

ad

Alignment

l

Type

(Side

In,

S

nsion

Measurem

dia

Tension

g

Europe

HOOT

QUIC

ment

ss

quality

ph

ment

can

be

d

nment

detai

nment

ding

he

heater

tem

d

gap

reduct

ed

with

med

e

to

reduce

q

k

missing

no

e

head

alignm

media

profile

ct

resol

eater

temp

s

k

duty

too

ent

data

wid

y

banding

sp

2,5)

Side

Out)

ent

CK

GUIDE

henomenon

done

for

2

m

Media

t

l,

please

refe

after

hea

mperature

an

tion

with

the

dia

Jam

quality

bandi

zzles

perf

ment

and

pa

e

and

Ink

Lim

ution

capabi

ettings

:

too

o

much

ink

w

th

or

Full

wid

ecification,

p

Head

A

input

T

Range:

SC

‐

S306

is

coming

fro

media

selectio

hickness

is

asked

er

to

section

ad

alignment

nd

media

rea

e

media

H

ng

:

form

light,

m

per

feed

has

mit

according

ility

regardin

high

tempe

will

increase

m

dth

?

depend

please

refer

Alignment

0.2

mm

Thickness.

0.1

‐

1.0

mm

600/610

Tech

om

wrong

he

on:

[

RIP

Sett

d

in

RIP

Settings

n

STEP

B

Cus

t

action

with

e

ead

strikes.

medium

or

he

s

been

perfo

g

media

capa

ng

your

signa

rature

decre

media

buckli

ding

on

signa

to

section

[

1

nical

Guide

ead

alignmen

ings

]

or

(

Me

use

aut

tomize

Setti

environment

Head

strikes

eavy

cleaning

rmed

with

th

bilities

age

applicatio

eases

quality

ing

age

applicati

1.

What

SC

‐

S

Head

A

●

Auto

●

Auto

●

Man

●

Man

[OK]

P

nt.

dia

xx

]

o

or

manual

ings

>

B2.

He

t,

some

medi

can

cause

in

g

(maintenan

he

media

loa

on

(Banners,

ion,

choose

t

S30600/610

C

Alignment

o

(Uni

‐

D)

o

(Bi

‐

D)

ual

(Uni

‐

D)

ual

(Bi

‐

D)

roceed

[

↖

]

Back

ead

Alignme

ia

can

buckle

nk

scratch

on

nce

menu)

aded

,

billboard,

e

the

correct

s

CAN

DO

]

k

P a g

ent

e

more

or

les

n

the

media

etc)

setting

e

|

16

ss

or