EPSON Stylus CX3500/CX3600/CX3650/CX4500/CX4600

Revision A

PRODUCT DESCRIPTION

Specifications

16

V

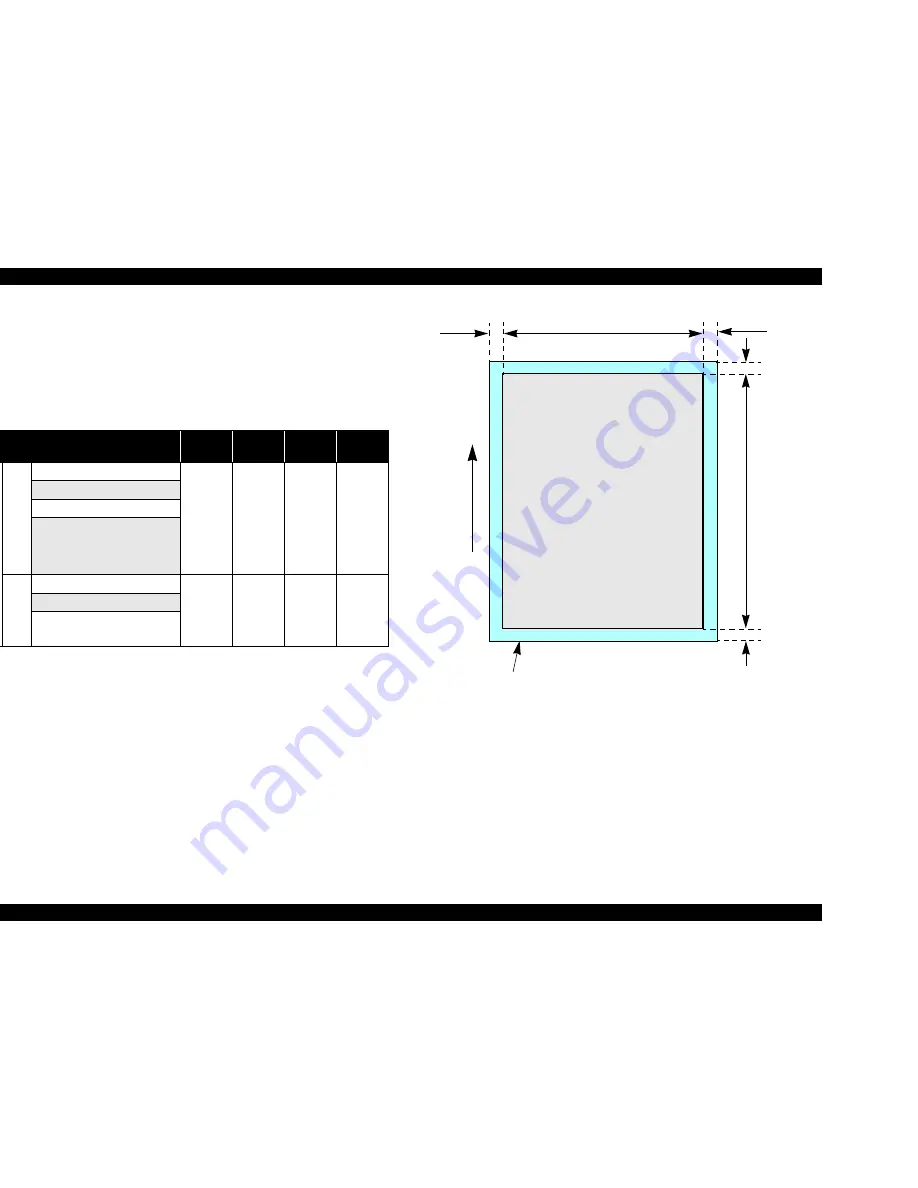

Cut sheet (border-free printing)

T

Printable area

For paper width (PW) and paper length (PL), refer to

“1.2.1.4 Paper Support ”

(p.12)

.

Refer to the following table. As for each overhang area, refer to

Figure 1-4

(p.16)

.

Figure 1-4. Printable area for Cut sheet (border-free printing)

Table 1-11. Applicable paper/Printing area

Paper type

Left

Overhang

Right

Overhang

Top

Overhang

Bottom

Overhang

E

x

cl

u

si

v

e pa

pe

r

Sty

lu

s C

X

35

00

/C

X

3

60

0/

C

X

36

50/

C

X

4

5

0

0

Photo Paper

2.5 mm

(0.09")

2.5 mm

(0.09")

3 mm

(0.12")

5 mm

(0.2")

Matte Paper Heavy Weight

DURABrite Photo Paper

Premium Semigloss Photo Paper

Sty

lus

C

X

46

00

Glossy Photo Paper

2.5 mm

(0.09")

2.5 mm

(0.09")

3 mm

(0.12")

5 mm

(0.2")

Matte Paper Heavy Weight

DURABrite Ink Glossy Photo

Paper

Paper size

LO

RO

PW

TO

BO

Paper Feed Direction

PL

Printable area

Содержание Stylus CX3500 Series

Страница 1: ...EPSON STYLUSCX3500 CX3650 CX3600 CX4500 CX4600 Color Inkjet Printer SEOT04 004 SERVICE MANUAL ...

Страница 8: ...C H A P T E R PRODUCTDESCRIPTION ...

Страница 52: ...C H A P T E R OPERATINGPRINCIPLES ...

Страница 79: ...C H A P T E R TROUBLESHOOTING ...

Страница 113: ...C H A P T E R DISASSEMBLYANDASSEMBLY ...

Страница 161: ...C H A P T E R ADJUSTMENT ...

Страница 174: ...C H A P T E R MAINTENANCE ...

Страница 181: ...C H A P T E R APPENDIX ...

Страница 200: ......

Страница 201: ......

Страница 202: ......

Страница 203: ......

Страница 204: ......

Страница 205: ......

Страница 206: ......