5.1 Carrier board recommended specifications

5.1.1 Planarity in finish process

Due to the technical and mechanical specifications of the connector we suggest the maximum planarity of the footprint on PCB, so we

suggest a type of finish obtained by horizontal process (we suggest and use for our carrier boards a type Chemical Gold finish).

5.1.2 Planarity of PCB

Also the planarity of the entire Printed Circuit Board must be kept in check especially when the carrier board grows in size. In this case

we suggest you contact the manufacturer of PCB to understand how improve the planarity of ended board and optimize the process

maintaining the electrical characteristics unchanged

5.1.3 Power Supply

It's strongly recommended that the power supply of the carrier board, which feeds the driver and control devices connected with the

i.MX processor, begins to work after the initialization of the processor itself

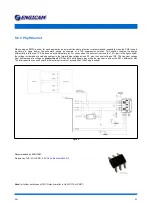

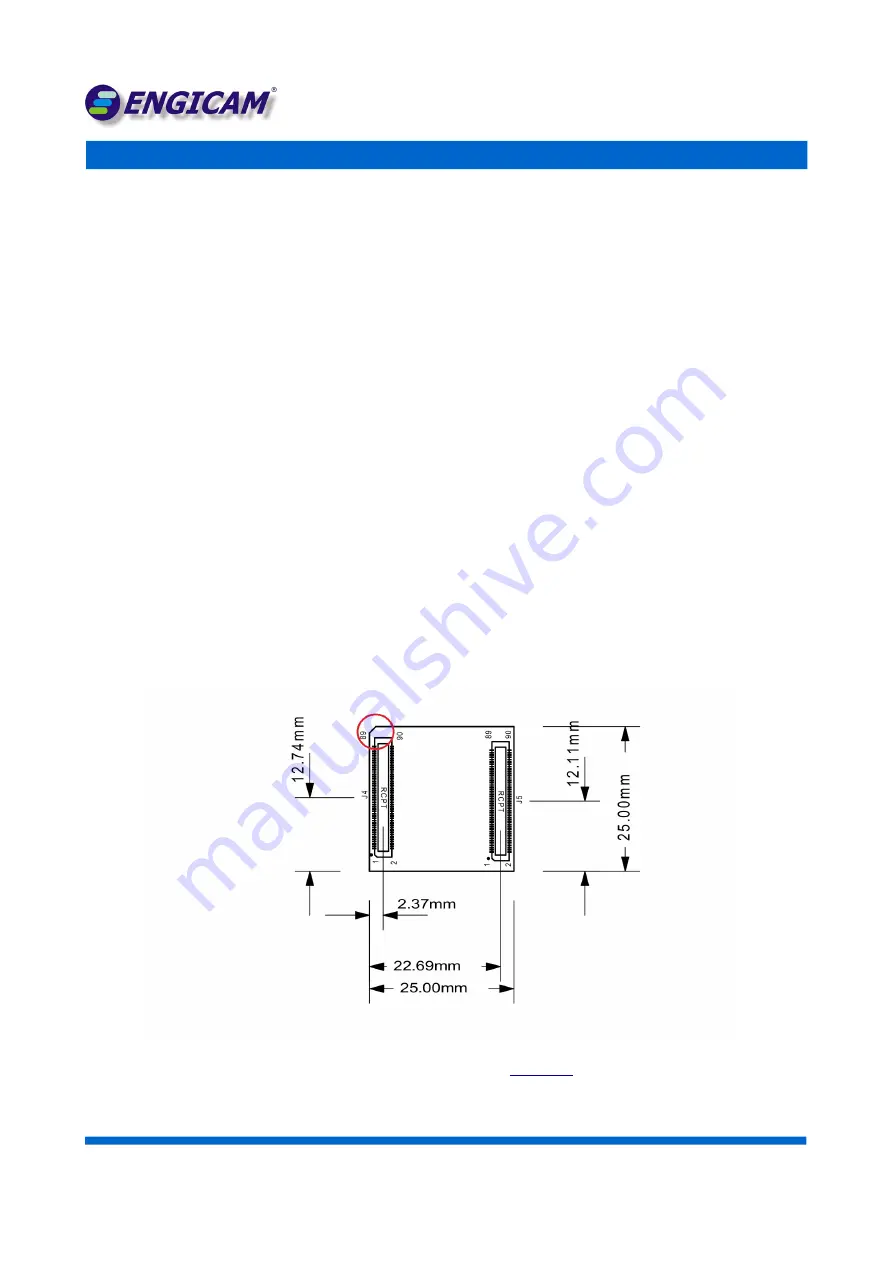

5.1.4 Module Positioning and fixing

Following, the mechanical positioning of the connectors on the carrier board used to insert the MicroGEA module

During the insertion pay attention to respect the direction given by the outline of the module and the silkscreen on the carrier

board (see the red circle in the figure)

Figure 3

Note: For information about carrier’s connector code and specifications, refer to

D N :

2 0