Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data HFI26xx

Operating Manual Rev. 1.3

www.engelantriebe.de

Page 11

6.3

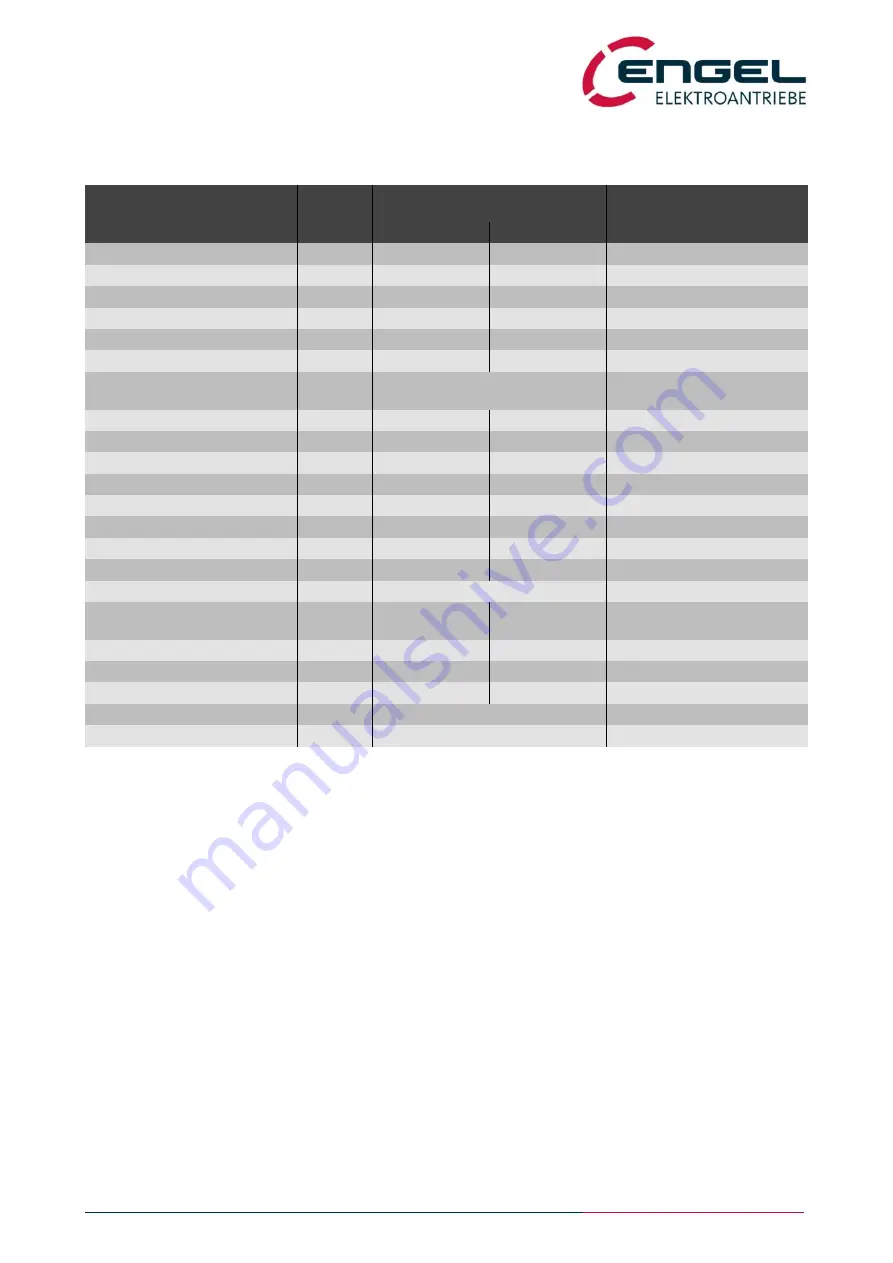

System Data HFI26xx

Designation

Unit

Value

additional information

HFI2630

HFI2660

Rated speed

min

-1

4000

3000

Peak speed

min

-1

5000

4000

Rated input current

*1)

ADC

8.8 / 4.4

10.6 / 5.3

24V-Type/48V-Type

Rated motor current

*2)

A

spk

13.2 / 6.8

17.9 / 8.9

24V-Type/48V-Type

Peak motor current

*2)

A

spk

26.5 / 13.7

37.5 / 18.5

24V-Type/48V-Type

Motor current measurement

range

A

55.0 / 27.5

Rated power

*3)

W

150

190

Rated torque

*3)

Nm

0.36

0.61

Peak torque

Nm

0.75

1.30

Torque constant

Nm/A

0.030 / 0.058

0.036 / 0.073

24V-Type/48V-Type

Voltage constant

V/1kmin

-1

3.6 / 7.0

4.4 / 8.8

24V-Type/48V-Type

Flange dimension

mm²

55 x 55

Drive length (without fieldbus

module)

*4)

mm

136 / 166

166 / 196

without/with parking brake

Weight

kg

1.2 / 1.45

1.6 / 1.85

without/with parking brake

Parking Brake (optional):

automatically operated

Static braking torque

Nm

2.0

Power (electric)

W

10

*1) The rated input current is the direct current drawn in nominal operation (rated torque at rated speed) from the input

voltage (24 VDC or 48 VDC). The current drawn from the input voltage is proportional to the converted power, not to

be confused with the torque-building motor current, which is displayed as sine peak value in DSerV and is propor-

tional to the motor torque.

Please also observe that the supply line is lossy. This leads to a reduction in voltage and speed at the motor system

and to increased power consumption of the device. A connection line with a nominal cross-section of 1.5 mm² al-

ready has an overall loss resistance of approx. 2 x 12.5 mΩ/m (conductors and return conductors)! Appropriate pow-

er reserves must be provided in the supply!

*2) Motor phase current as a sine peak value, which is required for the generation of the rated or peak torque. Motor

phase current is displayed in DSerV. Not to be confused with the current taken from the supply.

*3) The specified values apply for the installation of the drive on a system surface made of aluminium (A = 0.1 m²,

d = 10 mm). It must be taken into consideration that the specified continuous output power must be derated for

thermally unfavourable couplings.

*4) With fieldbus module the length of the drive increases by 14 mm.