5

1

★

DC5138190

1

Body

2

★

BC2514027F

1

Set Screw

3

★

B1003503

1

O-Ring

4

★

DC5127007

1

Plug

5

★

A8126110

1

Spring

6

★

DC5125013

1

Guide

7

★

B1003016

1 1/8 Dia. Ball

8

★

B1223503

1 O-Ring

9

★

B1001123

1 Nut

★

DC5124290

1

Seat

(not shown) (See Fig. 3)

★

P20037 1

Gasket

(not shown) (See Fig. 3)

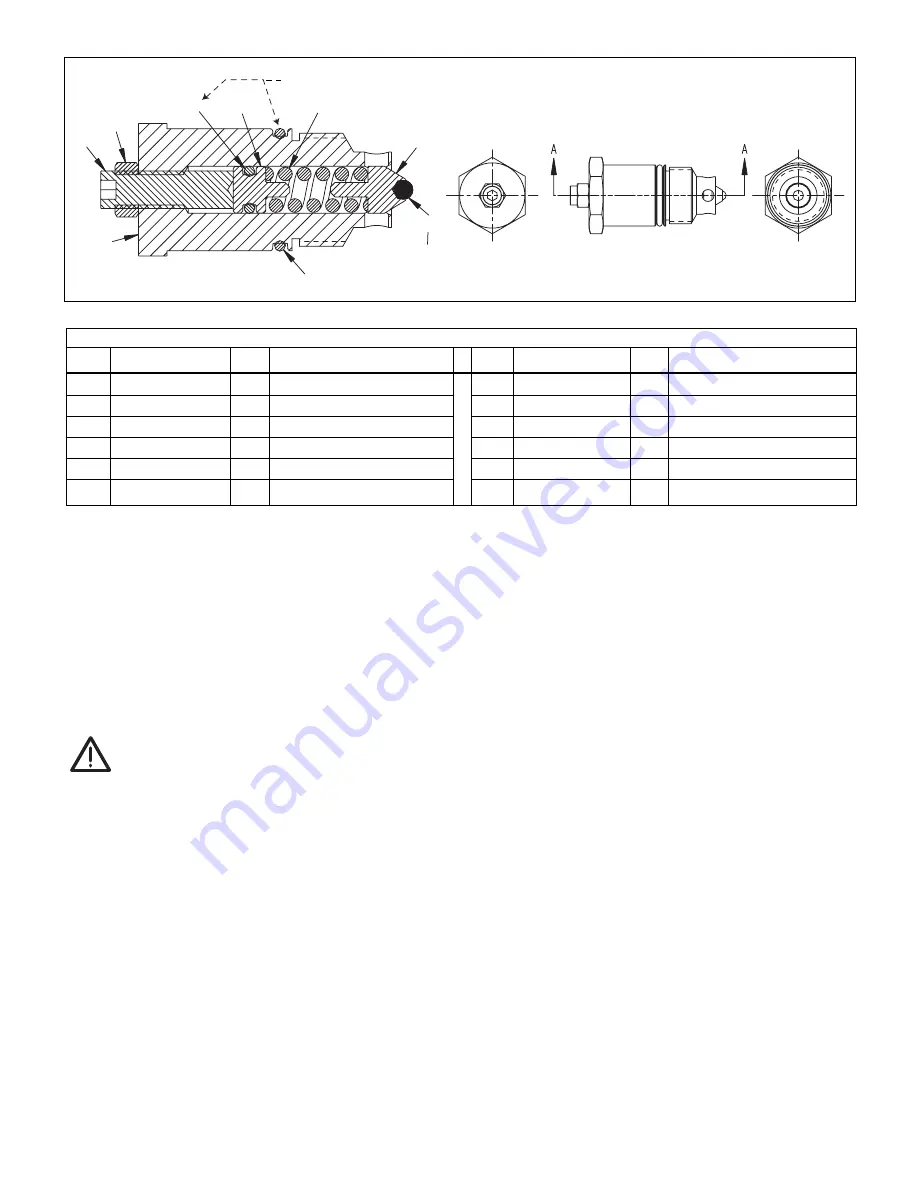

Repair Parts List for Figure 6, User Adjustable Relief Valve Assembly

Item Part Number

Qty.

Description

Item

Part Number

Qty. Description

1

8

2

9

3

4

5

6

7

Grease before assembly.

Figure 6, User Adjustable Relief Valve Assembly

TROUBLE SHOOTING AND REPAIR OF VE32 AND VE32D ELECTRIC VALVES

In diagnosing malfunctioning valves, certain symptoms

may be common not only to valves, but often to hydraulic

equipment in general. Before repairing the valve, mount

a different VM32 onto the pump and verify that the

problem is not with the pump.

TROUBLESHOOTING:

CAUTION:

Standard safety procedures are to be followed

during assembly to minimize any possibility of

injury.

1. Inability to obtain any pressure may be the result

of damaged connector seals on the pump, or failed

relief valve components (items 6,7 figure 6), or a

damaged check valve (item 3, figure 5C), or an

indication that the valve stack (item 1, figure 5C)

needs to be rebuilt. These problems are usually a

symptom of contaminated hydraulic oil. The system

should be drained and refilled with fresh ENERPAC

hydraulic oil.

2. Pressure leaks that are consistent and increase

proportionately with increasing pressure ranges are

usually the result of leaking gaskets or threaded

surfaces such as NTPF fittings or plugs.

3. Ball seat leakage is often erratic and intermittent and

is caused by contaminants trapped on the sealing

edge. Over time, as wear occurs, the check valve

and the valve stack (item 1, figure 5C) will need to be

replaced.

4. Leakage observed on the external surfaces is an

indication that the oring (item 13, figure 2, item 4,

figure 5C) and o-ring (item 6, figure 6) needs to be

replaced.

DISASSEMBLY:

1. Remove the 4 socket head cap screws and remove

the valve from the pump (item 76,figure 4A).

2. Remove the return tube (item 75) and gasket (item

70,figure 4A).

3. Remove the 4 socket head cap screws (item 3, figure

5A) and remove the poppet valve assembly.

4. Inspect the 3 o-rings (item 13, figure 2, item 4, figure

5C) for damage such as nicks, cuts, extrusion of

material. Replace if necessary.

5. Remove set screw (item 9, figure 2).

6. Remove valve plug (item 3, figure 2).

7. Remove solenoid stem (item 6, figure 2).

8. Remove valve stack (items 1A thru 1H, figure 2).

9. Inspect o-rings and glyd spring for damage such as

nicks or cuts. Replace if necessary.

10. The poppet valve stack (item 1G, figure 2) is a

matched subassembly. This part is only available as

a pre-assembled component.

11. Inspect the bore in the body (item 2, figure 2) for

Press Item 7 into Item 6 to 100 psi using a 10-ton press. Insert guide

and ball onto end of AT-0325c to help hold in place during pressing.

★

Indicates items included in and available only as a part of Repair Kit DC5139900SR.

Содержание VE32

Страница 26: ...VE32 VE32D VE32N LOMAR FT 1380 3 1 L2612 Rev D 03 10 26...

Страница 27: ...27...

Страница 28: ...VE32 VE32D VE32N LOMAR FT 1380 3 1 L2612 Rev D 03 10 28...

Страница 29: ...29...

Страница 30: ......

Страница 31: ......