16

10.6 Cutter Blade Replacement

NOTICE:

WARNING

• Always disconnect cutter from AC power supply

before beginning blade replacement procedures.

Failure to observe this precaution could result in

accidental startup during blade replacement. Serious

personal injury could result.

• Use extreme caution when removing and installing

blades. Blades may be sharp even when worn. To

avoid hand injury, wear appropriate personal

protective equipment (PPE) and avoid contact with

blade cutting edges.

10.6.1 Blade Wear

The use of worn blades decreases the effectiveness of

the cutter and can also side load the cylinder, resulting

in possible damage to the tool. Motor overheating can

also occur.

Replace blades immediately if they are worn and/or

damaged or if there has been a noticeable decrease in

cutting performance.

NOTICE

Blades are not sharpenable and must be

replaced when worn. To help ensure optimum cutting

performance, replace both the fixed blade and the

moving blade at the same time.

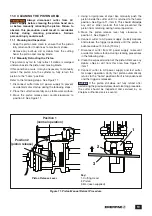

27. Move the piston release lever to position 1 and

tighten.

28. Connect the cutter to the AC power supply.

NOTICE:

WARNING

To avoid serious personal injury, stay

clear of cutting head and blades during the following

procedures.

29. Start the cutter and cycle the piston through several

advance and return strokes. Ensure that piston is

fully retracted when done.

NOTICE

Orient the oil reservoir cap facing upwards at

this time, and keep it as such until the cap is installed for

the final time. Failure to do so may result in air remaining

in the reservoir. This may require special consideration

when the soft metal bar is used.

30. Do not operate cutter for several hours (preferably

overnight) to allow any remaining air to separate

from the oil.

31. Place the soft metal bar (refer to step 2) into the

cutting head.

32. Press and release the trigger in short bursts until

the piston is extended as far as possible, but before

it makes a full cut and retracts. The moving blade

will become lodged in the bar, preventing the

piston from retracting. This procedure is necessary

because the cutter mechanism alone may fail to

hold the piston in the partially extended position as

oil level is being checked.

NOTICE

If you cut completely through the bar, try again,

cutting as far as you can without making a full cut.

33. Disconnect the cutter from the AC power supply

to prevent accidental motor start-up during the

following steps.

34. Loosen and remove the oil reservoir cap. Check

the oil level in the oil drain/fill hole. If oil level has

dropped, add additional Enerpac HF oil until the oil

level is up to the top of the hole.

35. Install and securely tighten the oil reservoir cap.

36. Move the piston release lever to position 2 to retract

the piston. If piston is stuck, use the bar to manually

push the piston back until it retracts.

37. Using a clean rag, wipe the cutter housing, grip and

motor so that surfaces are free of oil residue.

38. Connect the cutter to the AC power supply. Cycle

the piston several times to test for proper operation

before placing the cutter back into service.

Содержание EFBE5017

Страница 23: ...Notes...

Страница 24: ...WWW ENERPAC COM...