L4213_h

7

The pump must also be equipped with a separate safety

pressure relief valve that opens if the system working

pressure exceeds 10,150 psi [700 bar]. Verify that the

pump safety relief valve is adjusted to the proper setting

before using the pump with the cylinder(s).

4.2 Hydraulic Oil Requirements

Use of Enerpac HF Series ISO 32 hydraulic oil is

recommended. Enerpac HF oil is available at your local

Enerpac Distributor or Authorized Service Center.

NOTICE

• Failure to use the correct oil type (high-quality ISO

32 hydraulic oil) may result in damage to cylinder

hydraulic components and will void the product

warranty.

• Be sure that the oil is clean. The oil cleanliness

should be maintained to a maximum level of

18/16/13 per the ISO4406 standard. If the oil

develops a milky, cloudy or dark appearance, it

should be changed immediately.

• To avoid overfilling and possible equipment

damage, add oil to the pump reservoir only after

all cylinder plungers are completely retracted and

system pressure is released.

• When using a hand-operated pump to power the

cylinder(s), it is permissible to use a high-quality

brand of ISO 15 hydraulic oil. The lower oil viscosity

will result in reduced pumping effort, especially in

cold weather conditions.

4.3 Hydraulic Connections

A single hydraulic coupler provides hydraulic flow

for both advance and retract functions. The coupler

is compatible with all Enerpac HCB Series hydraulic

hoses.

The coupler size varies depending on cylinder model:

• Models CULP10 through CULP50 are equipped

with one 1/4”-18 NPTF female coupler (Enerpac

AH630).

• Model CULP100 is equipped with one 3/8”-18

NPTF female coupler (Enerpac CR400).

Be certain that all couplers are fully connected, so that

hydraulic flow is not blocked or restricted.

All hoses, fittings and other hydraulic components in the

circuit must be rated for at least 10,150 psi [700 bar]

operation.

4.4 Air Removal

Trapped air must be removed from the hydraulic cylinder

and hose before placing the system into operation. If

multiple cylinders are to be used, it is recommended

that air be removed from each cylinder individually.

Refer to the following procedure:

1. Place the cylinder in the vertical position, on a

flat surface. Be sure that there is no load on the

plunger.

2. Position the hydraulic pump so it is located higher

than the cylinder.

3. Operate pump and valve to SLOWLY advance the

plunger.

4. Relieve hydraulic pressure. Then, manually retract

the plunger into the cylinder base until it is fully

retracted. Use of a hydraulic pump equipped with

a vacuum valve will help aid plunger retraction.

5. Repeat steps 3 and 4 until the plunger advances

smoothly.

6. Be sure that the plunger is fully retracted. Then,

check the oil level in the pump hydraulic reservoir.

If oil level has dropped, add additional oil to the

reservoir as required.

NOTICE

Follow the pump manufacturer instructions when adding

oil to the pump reservoir. To avoid overfilling, be certain

that the cylinder plunger is fully retracted before adding

any oil.

7. Repeat steps 1 through 6 for all cylinders to be

used in the hydraulic circuit.

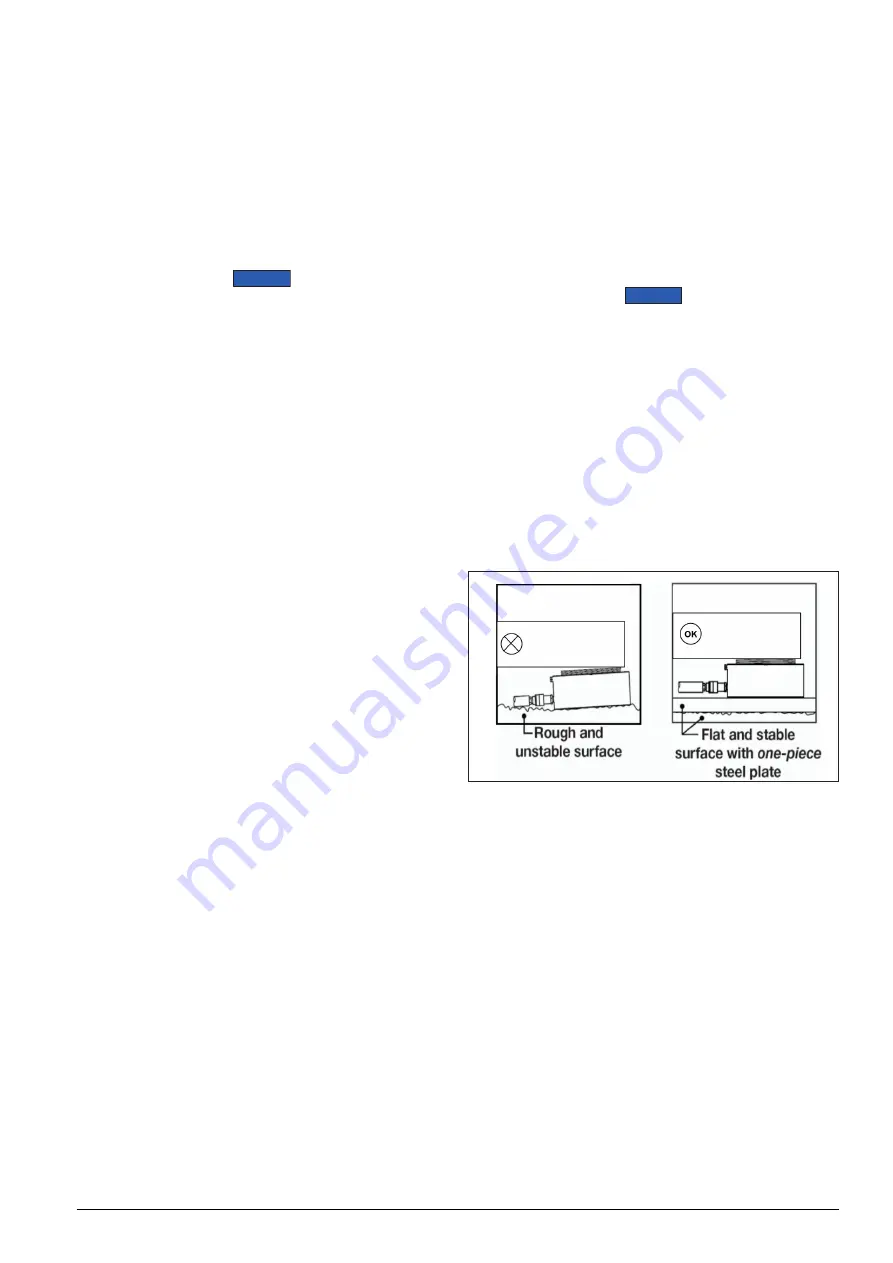

4.5 Cylinder Base Support

Be certain to provide adequate support for the cylinder

base. All CULP Series cylinders require a flat and stable

lifting surface that is capable of supporting the load

without settling. A one-piece steel plate of appropriate

size should be placed between the cylinder base and

the ground or other lifting surface.

Figure 3: Cylinder Base Support

Use of CULP Series cylinders on surfaces such as sand,

mud or dirt may result in loss of load and/or damage to

cylinder.

Always use a one-piece steel plate under a CULP Series

cylinder. To ensure proper support, be sure that the

plate extends under the entire surface of the cylinder

base. The cylinder base may become deformed and

permanently damaged if these instructions are not

followed.

4.6 Avoiding Side Load

Plan ahead to eliminate the presence of side load

forces (offset loading) when using hydraulic cylinders.

Side load can occur as a result of one or more of the

following conditions:

• An eccentric load on the plunger.

• A horizontal load on a structure.

• A shifting center of gravity.

• Structure and/or cylinder misalignment.

Содержание CULP10

Страница 2: ......

Страница 16: ...2022 Enerpac Tool Group All Rights Reserved www enerpac com...