4S-SERIES PRESSURE EXCHANGER ENERGY RECOVERY DEVICES

Energy Recovery, Inc.

10

ERI Document Number 80022-01-04

5.0 INSTALLATION

The 4S-series PX energy recovery device can be installed in horizontal, vertical or any other

orientation. The PX-45S, -70S and -90S have four connections labeled HP IN, HP OUT, LP IN,

and LP OUT. The PX-140S has dual HP OUT and LP IN connections and single HP IN and LP

OUT connections.

•

HP IN

is the high-pressure reject/brine inlet.

•

HP OUT

is the high-pressure seawater outlet.

•

LP IN

is the low-pressure seawater inlet.

•

LP OUT

is the low-pressure reject/brine outlet.

The external fittings on the PX energy recovery device are made with AL-6XN

®

, 254 SMO

®

, or

equivalent stainless steel. The vessel is made of glass-reinforced plastic. Proper piping, piping

support, and vessel support must be implemented to minimize external stresses on all piping

fittings. Bearing pads should be used to avoid abrasion of the vessel. Flexible couplings should

be used for joining fittings and piping. Use only water-soluble lubricants such as glycerin or soap

on all O-rings and seals. Do not use grease! Section

13.0

contains an installation diagram/piping

detail for use for piping, manifold, and support rack design.

6.0 OPERATION

6.1 System Performance Specifications, Precautions and Conditions

Successful operation of the PX Pressure Exchanger energy recovery device requires observation

of some basic operating conditions and precautions. The PX unit must be installed, operated, and

maintained in accordance with this manual and good industrial practice to assure safe operation

and a long service life. Failure to observe these conditions and precautions can result in violation

of the warranty, damage to the equipment, and/or harm to personnel. Table 6-1 provides a

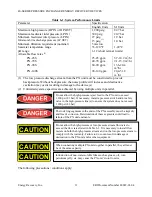

summary of system performance limits.

®

Trademark of Allegheny Ludlum Corp.

®

Trademark of Avesta Sheffield AB

Thoroughly flush associated piping with water filtered to 5 microns

before installing the PX unit. Foreign material may cause damage.

The PX unit must not be supported by its pipe fittings, nor should the PX

unit be allowed to support piping or manifolds. During installation do not

lift the PX by the ports.

A pressure gauge should be installed near each pipe connection to the PX

unit or PX unit array to facilitate monitoring of PX unit performance.

CAUTION

CAUTION

CAUTION