IM7310A Rev A

5

April 7

th

, 2020

5.1.

Mounting Surface

The mounting surface should be clean and free of burrs. Two #0-80 tapped holes, 0.2 inch minimum depth should be

spaced 0.3 inches (7.62 mm) apart. A 32 micro inch rms surface finish with flatness of 0.0001 inches is

recommended for the area that will contact the angular rate sensor. The rotational axis of the unit is perpendicular

to the mounting surface, so the angular alignment of the two mounting holes is not critical. The location of the

mounting holes is not critical either, the angular rate sensor can be mounted at the center or close to the edge of the

mounting surface of the rotational substrate.

5.2.

Screw Mount

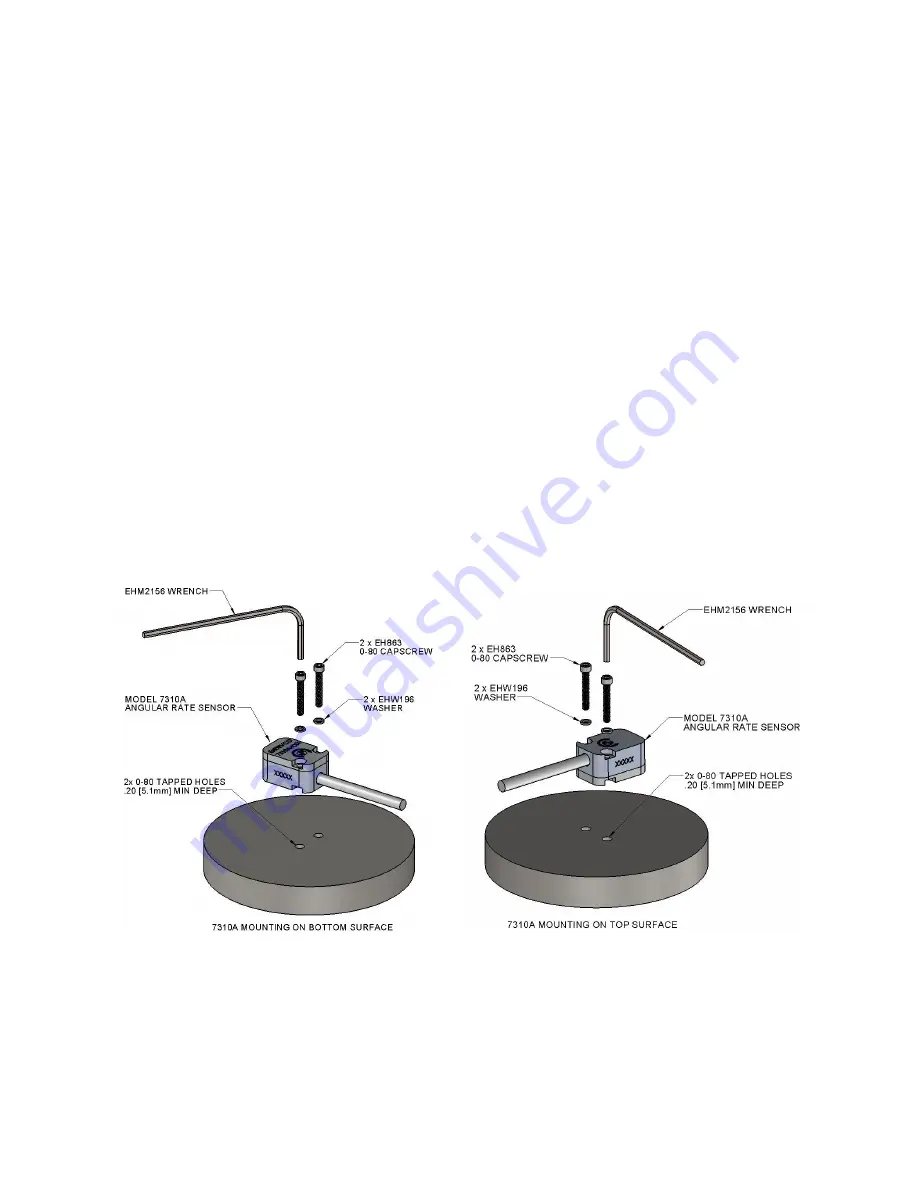

To screw mount Model 7310A to mounting surface, use the supplied mounting washers (EHX196, 18-8 CRES),

mounting screws (EH863, 0-80 x 3/8’’, alloy steel, black oxide finish) and Allen wrench (EHM2156, alloy steel, black

oxide finish) as shown in Figure 1.

Remove the unit from the shipping container. Place the unit on the mounting surface and align the mounting holes.

Slide the washers over the screws. Using the supplied wrench or a torque wrench, tighten the screws to 4 lbf-in (0.45

Nm). This is roughly equivalent to finger tight with the supplied wrench.

The Model 7310A angular rate sensor can be mounted on either the bottom surface of the sensor, as shown in Figure

1(a), or the top surface of the sensor, as shown in Figure 1(b). The rotation arrow mark printed on the top and

bottom surface of the angular rate sensor indicates the positive rotation direction. When mounted on bottom

surface, the angular rate sensor outputs a positive voltage in response to a clockwise rotation. When mounted on

top surface, the angular rate sensor outputs a positive voltage to an anti-clockwise rotation.

FIGURE 1 (Left) Screw Mount of Model 7310A Angular Rate Sensor (on sensor bottom)

(Right) Screw Mount of Model 7310A Angular Rate Sensor (on sensor top)