3

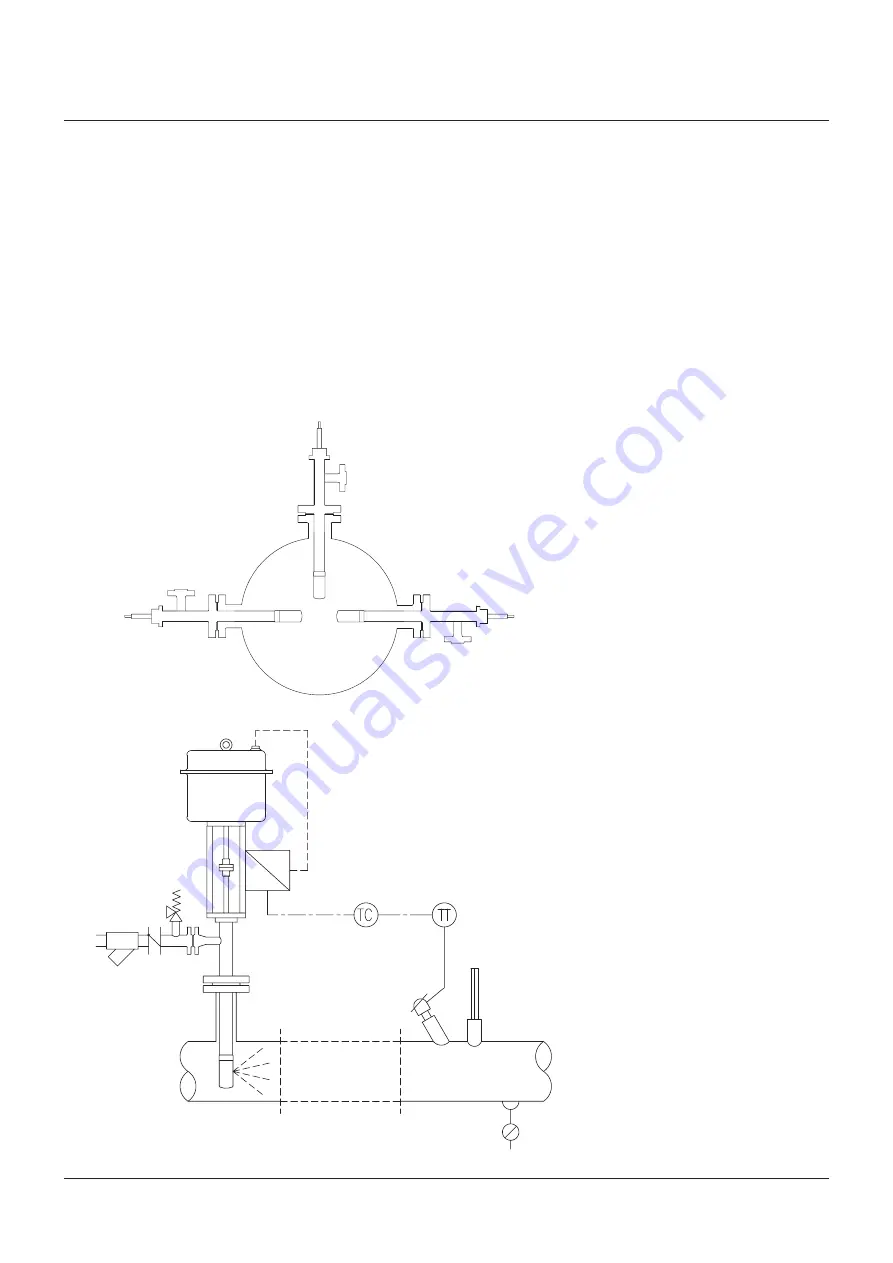

Figure 6

safety valve

Check valve

strainer

YarwaY

A.T.-Temp CryogeniC desuperheATer sTAndArd duTy

InstallatIon and MaIntenance InstructIons

The liquid supply should be of a good quality;

clean and filtered, and should have a constant

pressure as specified in the order documents.

each liquid supply line should be protected with

its own individual strainer with a maximum

element perforation size of 0.1 mm (0.4 mm

acceptable for nozzles ‘e’ size and up).

Where there are positive shut-off components

in the liquid supply (including electric actuators)

then a safety relief valve of an approved type

should be fitted. As in the case of the process

pipework, use gasketing and bolting in

accordance with the relevant piping code. Flush

out the liquid line before connecting to the

A.T.-Temp Cryogenic desuperheater mounting

flange (see Figure 6).

Figure 5

yarway supplies the A.T.-Temp Cryogenic

desuperheater as follows:

identification number:

xx. 37. xxxxx - Fabricated type with

non-balanced stem.

xx. 47. xxxxx - Fabricated type with

semi-balanced stem and

oversized trim all with the spray

cylinder tack welded to the body

extension pipe.

note:

horizontal orientated A.T.-Temp

Cryogenic desuperheater has to be installed

with a support for weight compensation.

pipe bends should always be of the long radius

type to assist in keeping the liquid droplets in

suspension, until complete evaporation has

taken place. installation may be in vertical or

horizontal piping, but the direction of liquid

injection should always be with the process

gas flow.

The A.T.-Temp Cryogenic desuperheater may

be mounted at 90° to the process pipe, for

all flow orientations, but avoid installation in

the vertically downwards position, wherever

possible (see Figure 5).