Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation

Parameters

Technical

data

Component

sizing

Diagnostics

Unidrive SP Regen Installation Guide

163

Issue Number: 2 www.controltechniques.com

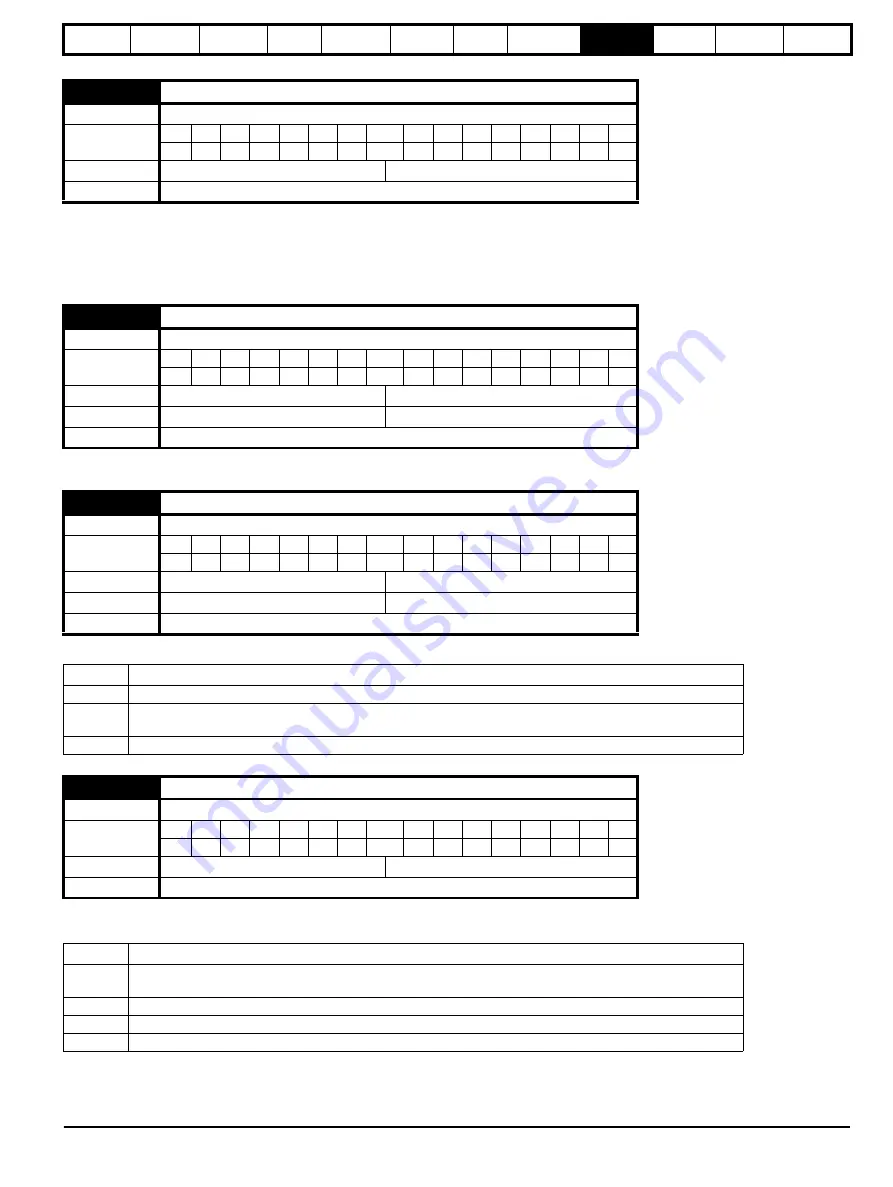

When this bit is set to one the motor 2 parameters in menu 21 become active instead of the equivalent parameters in other menus. Changes will only

be implemented when the drive is disabled. When the motor 2 parameters are active the decimal point that is second from the right on the 1st row of

the display is lit. If this parameter is one when an auto-tune is carried out (Pr

5.12

= 1), the results of the auto-tune are written to the equivalent

second motor parameters instead of the normal parameters. Each time this parameter is changed the accumulator for motor thermal protection is

reset to zero.

Displays the number of the last set of defaults loaded, i.e. 1233, 1244, etc.

This parameter is used to start and stop the drive Onboard PLC program.

The drive Onboard PLC program status parameter indicates to the user the actual state of the drive Onboard PLC program. (not fitted / running /

stopped / tripped.)

11.45

Motor 2 parameters select

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV PT US RW BU PS

1

1

1

Default

Regen

0

Update rate

Background

11.46

Defaults previously loaded

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV PT US RW BU PS

1

1

1

1

Range

Regen

0 to 2,000

Default

Regen

Number of defaults loaded, i.e. 1,233 etc.

Update rate

Background

11.47

Drive Onboard PLC program enable

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV PT US RW BU PS

1

1

1

Range

Regen

0 to 2

Default

Regen

2

Update rate

Background

Value

Description

0

Halt the drive Onboard PLC program.

1

Run the drive Onboard PLC program (if fitted). Any out-of-range parameter writes attempted will be clipped to the

maximum / minimum values valid for that parameter before being written.

2

Run the drive Onboard PLC program (if fitted). Any out-of-range parameter writes attempted will cause a drive trip.

11.48

Drive Onboard PLC program status

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV PT US RW BU PS

1

1

1

Range

Regen

-128 to +127

Update rate

Background

Value

Description

-n

Onboard PLC program caused a drive trip due to an error condition while running rung n. Note that the rung

number is shown on the display as a negative number.

0

Onboard PLC program is not fitted.

1

Onboard PLC program is fitted but stopped.

2

Onboard PLC program is fitted and running.

Содержание SP1201

Страница 219: ......

Страница 220: ...0471 0029 02 ...