6

PENBERTHY

SERIES U FLAT GLASS GAGES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

8 REMOVAL - DISASSEMBLY - REASSEMBLY

WARNING

Use only qualified, experienced personnel who

are familiar with liquid level gage equipment and

thoroughly understand the implications of the

tables and all the instructions. DO NOT proceed

with any maintenance unless the liquid level gage

has been relieved of all pressure or vacuum, has

been allowed to reach ambient temperature and

has been drained or purged of all fluids. Failure

to follow instructions can cause serious personal

injury and property damage.

8.1 Disassembly

Secure a workbench longer than the liquid level

gage, and sufficiently wide to lay out parts as

they are removed.

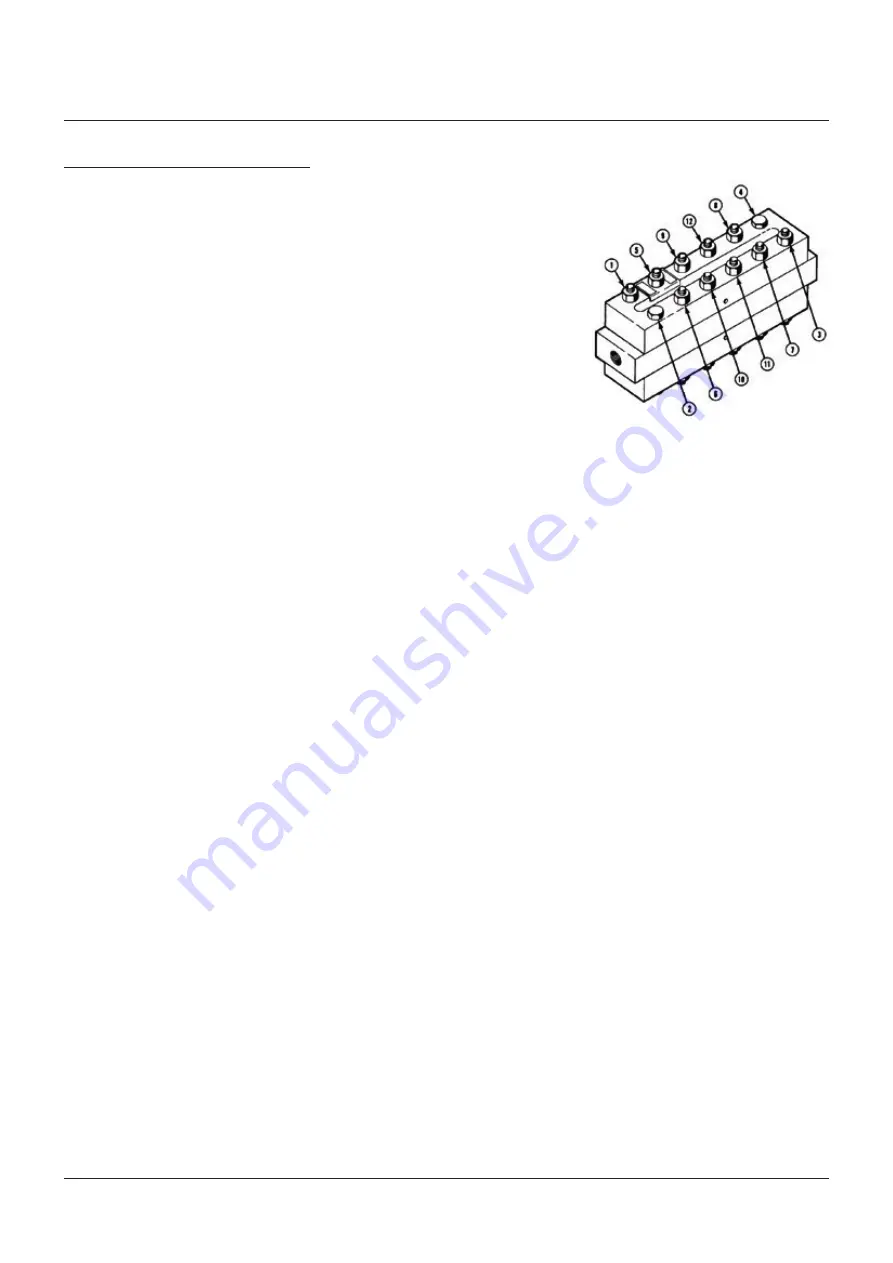

1. Hold gage firmly; loosen cap screws and

nuts starting at both ends of each section

and then proceed from both ends to the

center of each section as shown in Figure 2.

Note:

if maintenance is to be performed on

one (1) side of the gage only, the cap screws

on the opposite side of the gage do not need

to be removed. If these screws are removed,

then all glass, gaskets and cushions on

both sides of the gage must be destroyed,

disposed of and replaced.

2. Nut loosening sequence

- Remove nuts, cap screws, washer and

nameplate.

- Tap covers with rubber hammer as needed

to loosen and remove.

- Remove cushions, glass and gaskets.

- Tap liquid chamber or remaining covers as

necessary with rubber hammer to break

loose and remove remaining components.

- Remove, destroy and dispose of all

glass, cushions and gaskets. Under no

circumstances should these components

be re-used or installed on a gage.

Note:

if size of gage is smaller than shown,

follow spiraling sequence from the ends

until all bolting is loosened.

WARNING

Once used, cushions and gaskets are deformed

permanently by compression and, if re-used,

may cause leaks and high stress points resulting

in glass breakage. Glass may contain hidden

damage and internal stresses caused by previous

usage. If re-used, the glass may break under

pressure causing severe personal injury or

property damage.

FIGURE 2

Nut loosening sequence

8.2 Inspection of glass seating surfaces

Clean the glass seating surfaces on the liquid

chamber and cover with a soft metal scraper

(preferably brass) to remove all burrs, rust and

remnants of the previous gaskets and cushions.

Exercise extreme care to avoid gouging or

scarring gasket and cushion seating surfaces.

Use a known flat piece of metal the same

approximate length as the glass or a new

piece of glass and a thickness gage to check

flatness of each glass seating surface on liquid

chamber and under cover. Surfaces on the

liquid chamber must be flat within 0.001 inch

(0.03 mm) and on the cover must be flat within

0.002 inch (0.05 mm). If any one surface is

found to be beyond the tolerances described

above, the entire gage must be disposed of and

replaced.

WARNING

Flatness of glass seating surfaces outside the

tolerances specified above is an indication of the

gage having been overstressed through repeated

exposure to mechanical, thermal or hydraulic

shock during its previous service. Operation of a

liquid level gage which has been overstressed will

result in abnormal stresses on the glass which

may cause glass to break with resulting sudden

release of pressure, leakage of contained fluid,

serious personal injury or property damage.

Glass seating surfaces should NOT be

machined to achieve seating tolerance. The

chamber and cover are designed for a critical

thickness to achieve the pressure/temperature

ratings. Machining glass seating surfaces may

result in non-compliance to the necessary

critical thickness due to material removal.