4

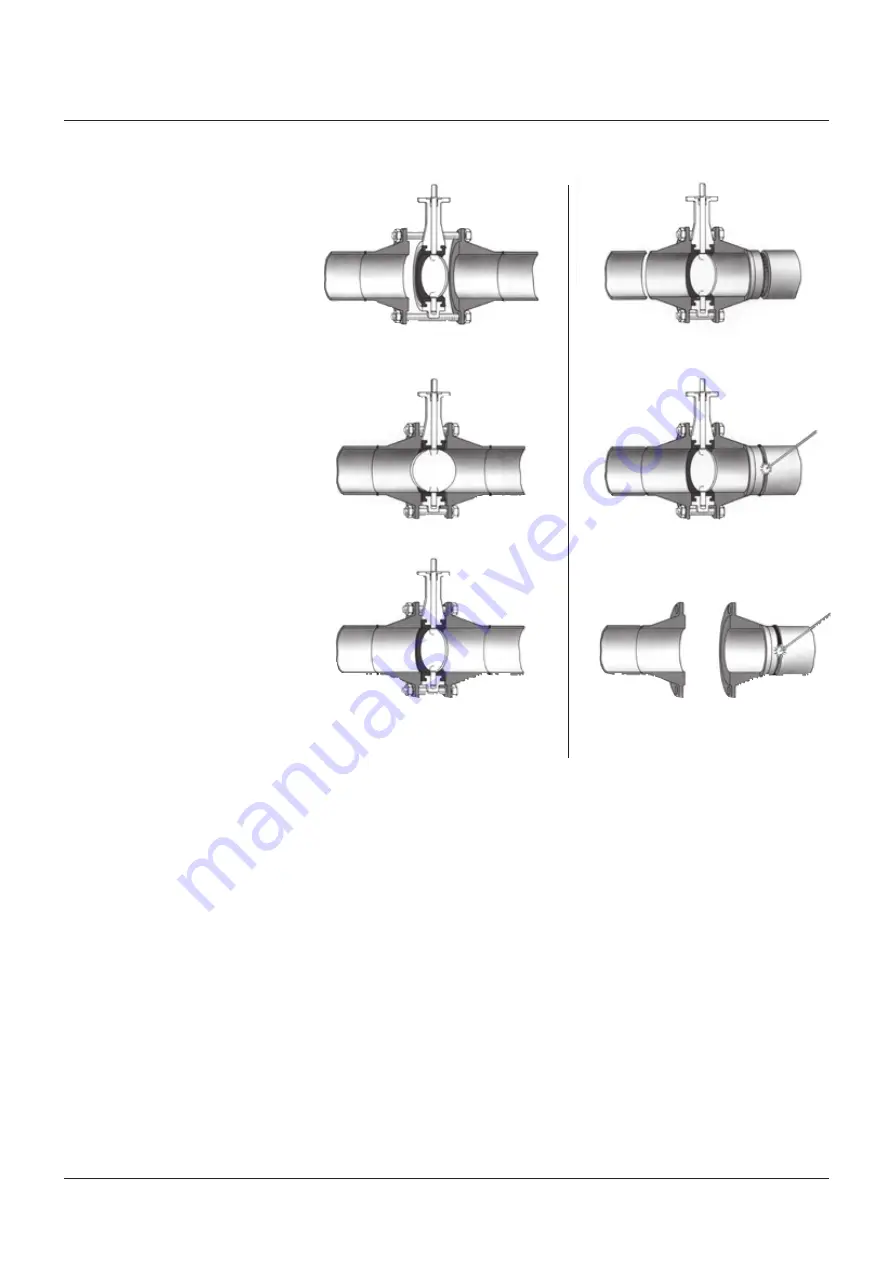

EXISTING SYSTEM

NEW SYSTEM

1. Spread the flanges with the adequate tooling.

Insert some flange bolts to hold the valve.

1. Center a flange-valve-flange assembly between

the pipes.

2. Open the valve and remove the flange spreads.

2. Tack weld the flanges to the pipes.

3. Close the valve clockwise, return to open position

and cross-tighten all bolting.

3. Remove the valve and finish weld.

Install the valve according to the procedure in the

left column.

KEYSTONE

SERIES 60 BUTTERFLY VALVES

INSTALLATION AND OPERATION MANUAL

FIGURE 2

3.5 Sources of possible danger

This section contains some examples of

possible foreseen danger sources.

3.5.1 Mechanical

A. When manual operators are used, available

space should be checked in order to avoid

hands being clamped.

B. Mechanical sparks caused on impact of

valve and e.g. tooling, are a potential source

of ignition of surrounding atmosphere.

3.5.2 Electrical

If static charges or stray electrical currents

can initiate explosions, the valve should be

grounded to earth.

3.5.3 Thermal

A. Isolation should be used on valves with

application temperatures > +40°C (+104°F)

and < -20°C (-4°F) to prevent them from

being touched (to avoid burning).

B. If the valve is used in hot gas/fluid

applications that might give exothermic

reactions, precautions must be taken so

that the valve surface cannot lead to danger

for people or the direct environment. In dust

and possible explosion zones, the operation

temperatures and ignition temperatures for

dust should be reviewed.

3.5.4 Operational

Closing a valve too fast may result in water

hammer in the upstream part of the pipeline.

Water hammer results in excessive stresses in

the valve and will cause severe damage.

Water hammer should be avoided in all

circumstances.

Due to differential pressure across the valve

disc, butterfly valves have the tendency to be

closed by the flow. Take care when unlatching

the valve operating mechanism.

Содержание KEYSTONE 60 Series

Страница 9: ... 2017 Emerson All rights reserved ...