4. Loosen the nut (key 16) while holding wrench flats on plug

(key 3) to inspect internal wetted parts. Remove the lock

washer (key 24) and flat washer (key 23). The lower spring

seat (key 8), guide ring (key 9), diaphragm (key 7) and plug

O-ring (key 3) can now be removed from the plug (key 2). An

optional lower diaphragm plate (key 10) and O-ring (key 4)

are included for the constructions offering protection against

vacuum conditions.

5. Remove the plug (key 2) through the inlet port of the body

(key 1). Inspect parts for damage. Replace if damage is

noted. Refer to the section titled Soft Seat Maintenance

when the seat needs to be replaced.

6. Reassemble in the reverse order of the above procedure.

Start by inserting the plug (key 2) through the inlet port of

the body (key 1). The order is listed below or please refer to

Figure 3.

a.) Plug (key 2)

b.) Plug O-ring (key 3)

c.) Diaphragm plate (key 10) (vacuum protection

construction only)

d.) Diaphragm plate O-ring (key 4) (vacuum protection

construction only)

e.) Diaphragm gasket (key 6) (Metal diaphragms only)

f.) Diaphragm (key 7)

g.) Diaphragm gasket (key 6) (Metal diaphragms only)

h.) Guide ring assembly (keys 9 and 5)

i.) Lower spring seat (key 8)

j.) Flat Washer (key 23)

k.) Lock Washer (key 24)

l.) Hex Nut (key 16)

7. Hold wrench flats on plug (key 2), then torque hex nut

(key 16) to 6 to 8 in-lbs / 0.7 to 0.9 N•m for the 1/2 and

3/4 in. / 15 and 20 mm, 5 to 7 ft-lbs / 7 to 9 N•m for the

1 and 1-1/2 in. / 25 and 40 mm and 28 to 30 ft-lbs /

38 to 41 N•m for the 2 and 3 in. After tightening, apply

threadlocker medium/high strength sealant or equivalent to

the nut/thread interface.

8. Position diaphragm assembly in body (key 1). Replace

regulator spring (keys 12 and 13, when applicable) and

upper spring seat (key 11). Replace the spring case

(key 14) and sanitary clamp (key 15). Torque clamp

nuts to 20 to 22 ft-lbs / 27 to 30 N•m for the 1/2 through

1-1/2 in. / 15 through 40 mm and 38 to 40 ft-lbs / 52 to

54 N•m for the 2 and 3 in. / 50 and 80 mm.

Note

Lubricate the adjusting screw (key 18) threads

and the sanitary clamp bolt threads (key 15) to

reduce galling of the stainless steel. Factory

recommends anti-seize lubricant.

Keep even spacing between clamp halves

when tightening clamp nuts. This will ensure

even loading of the diaphragm. If clamp

halves touch, please contact factory for a

replacement clamp.

9. Install in pipeline and follow Startup and

Adjustment procedures.

Soft Seat Maintenance

Take care not to damage the internal/wetted surface finish when

performing Soft Seat Maintenance.

1. Disassemble the regulator as stated above.

2. To access soft seat (key 28), unscrew the lower plug

(key 27) from the upper plug (key 26). If damaged, replace

with new part. Apply Loctite 246 or equivalent to the male

threads before assembly. Proper torque for the assembly is

6 to 8 in-lbs / 0.7 to 0.9 N•m for the 1/2 and 3/4 in. / 15 and

20 mm; 8 to 10 in-lbs / 0.9 to 1.1 N•m for the 1 and 1-1/2 x

1 in. / 25 and 40 x 25 mm; and 5 to 7 ft-lbs / 7 to 9 N•m for

the 1-1/2 in. / 40 mm. Torque for 2 and 3 in. / 50 and 80 mm

is 23 to 25 ft-lbs / 31 to 34 N•m.

3. Reassemble as stated in the prior section.

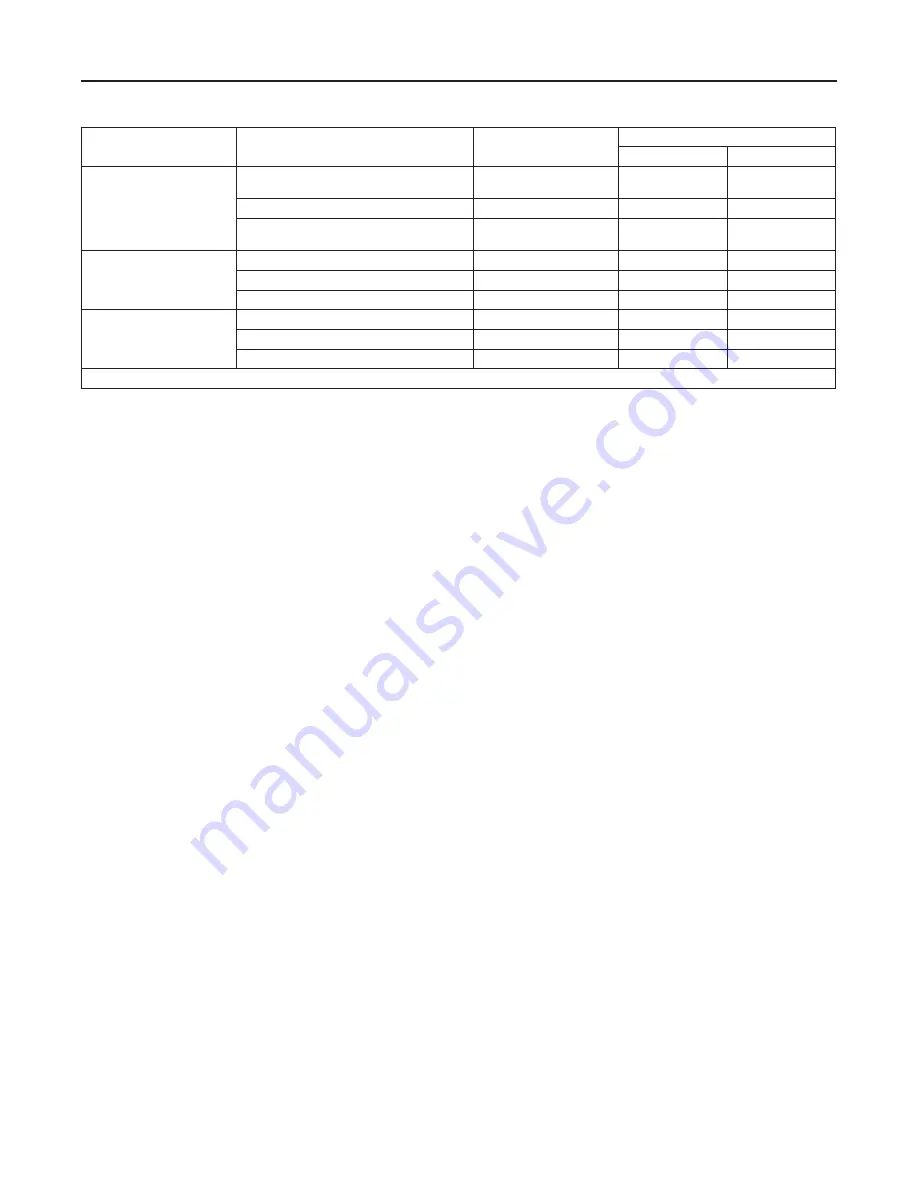

Table 4.

Temperature Capabilities

SEAT TYPE

DIAPHRAGM MATERIAL

O-RING MATERIAL

TEMPERATURE RANGE

°F

°

C

Metal

(Stainless Steel)

Ethylene Propylene Diene (EPDM)/

Stainless Steel

EPDM

-20 to 275

-28 to 135

Stainless Steel

PTFE/Fluorocarbon (FKM)

(1)

20 to 400

-6 to 204

Polytetrafluoroethylene (PTFE)/

Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

20 to 400

-6 to 204

Soft

(Polytetrafluoroethylene

(PTFE)/Stainless Steel)

EPDM/Stainless Steel

EPDM

-20 to 150

-28 to 65

Stainless Steel

PTFE/Fluorocarbon (FKM)

(1)

20 to 150

-6 to 65

PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

20 to 150

-6 to 65

Soft

(Polyether Ether Ketone

(PEEK)//Stainless Steel)

EPDM

EPDM

-20 to 275

-28 to 135

Stainless Steel

PTFE/Fluorocarbon (FKM)

(1)

20 to 400

-6 to 204

PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

20 to 400

-6 to 204

1. O-ring material is PTFE for the 1/2 and 3/4 in. / 15 and 20 mm sizes. Temperature range is the same.

6

Type SR5