2502 Series Controllers

Instruction Manual

Form 1446

November 2006

14

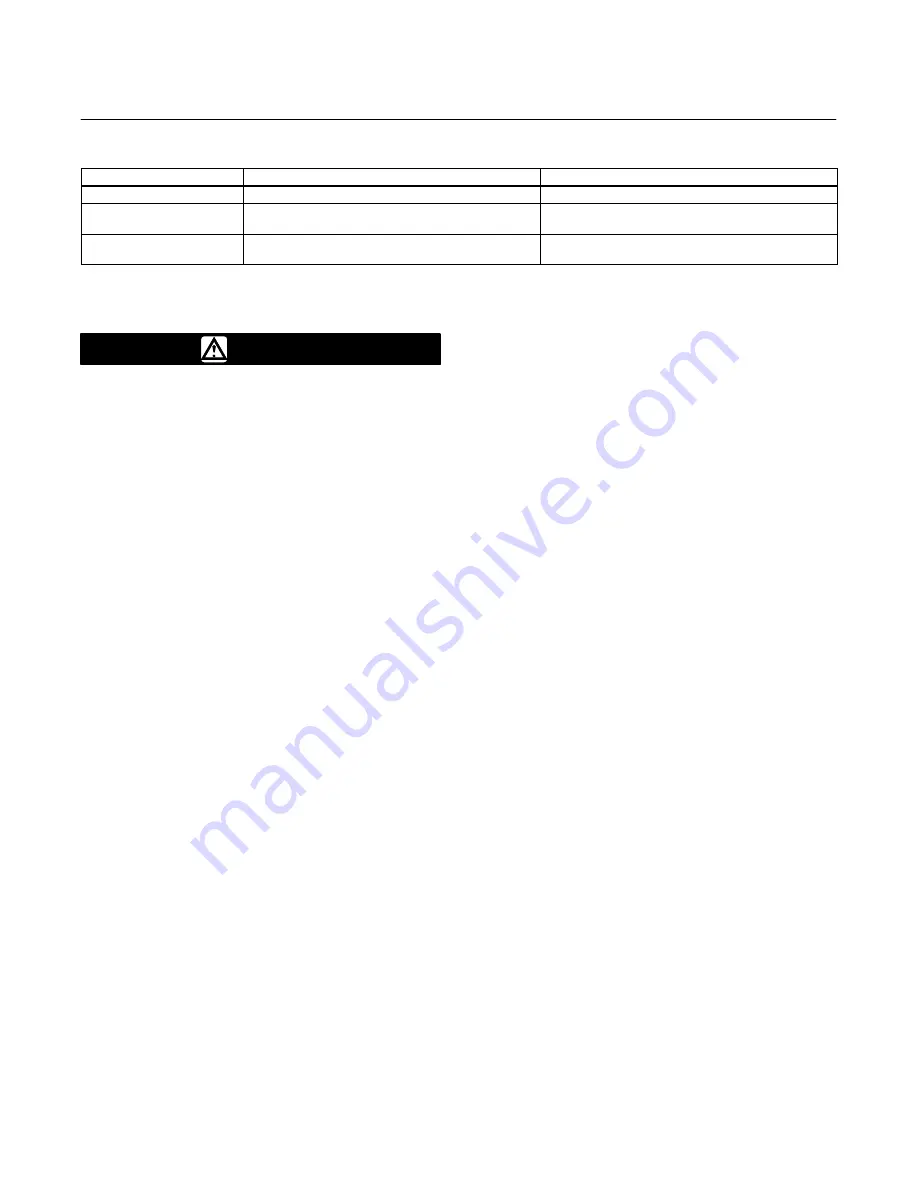

Table 2. Minimum and Maximum Limits for Setting Process Variables

Application

Minimum Limit

Maximum Limit

Liquid level

Displacer must be completely out of liquid

Displacer must be completely submerged in liquid

Interface

Displacer must be completely submerged in the upper

of two process liquids

Displacer must be completely submerged in the lower

of two process liquids

Density

Displacer must be completely submerged in liquid having

highest specific gravity expected

Displacer must be completely submerged in liquid

having the lowest specific gravity expected

Calibration Procedure

WARNING

The following calibration procedure

requires taking the controller out of

service. To avoid personal injury and

property damage caused by an

uncontrolled process, provide some

temporary means of control for the

process before taking the controller

out of service.

Figure 9 shows adjustment locations for the

following steps, except as otherwise indicated. When

calibrating, open loop conditions must exist. One

way to obtain an open loop is to place the final

control element into manual control or bypass it. If

there is no provision for manual control, shut down

the process. It is recommended that a test pressure

gauge be installed in the controller output line for

subsequent calibration steps.

Several steps in these calibration procedures require

setting the process variable at its minimum and

maximum limits according to table 2. Reverse-acting

controllers produce the opposite response.

1. Connect a supply pressure source to the

controller and provide a supply pressure suitable for

the sensing element range: 1.4 bar (20 psig) for

a 0.2 to 1.0 bar (3 to 15 psig) output pressure range

or 2.4 bar (35 psig) for a 0.4 to 2.0 bar (6 to 30 psig)

output pressure range.

2. Rotate the reset knob to 0.01 minutes per repeat.

3. Rotate the proportional band knob to zero.

4. Set the liquid at the minimum limit (dry displacer).

5. Turn the RAISE LEVEL knob to zero.

6. Adjust the nozzle until output pressure is

between 0 and 0.2 bar for a 0.2 to 1.0 bar signal

range (0 and 3 psig for a 3 to 15 psig signal range)

or 0 and 0.4 bar for a 0.4 to 2.0 bar signal range (0

and 6 psig for a 6 to 30 psig signal range).

7. Set the liquid at the maximum limit (covered

displacer).

8. Turn the RAISE LEVEL knob until the output

pressure is 1.0 bar for a 0.2 to 1.0 bar signal range

(15 psig for a 3 to 15 psig signal range) or 2.0 bar for

a 0.4 to 2.0 bar signal range (30 psig for a 6 to 30 psig

signal range).

9. The controller is within its calibration accuracy if

the RAISE LEVEL knob is between the 9.0 and 10.0

positions.

10. If the controller is out of calibration, adjust the

calibration adjuster as follows:

Note

Loosen the two calibration adjuster

screws (key 45, figure 14), and slide

the calibration adjuster (key 100, figure

a. If output is

below

1.0 bar for a 0.2 to 1.0 bar

signal range (15 psig for a 3 to 15 psig signal

range) or 2.0 bar for a 0.4 to 2.0 bar signal range

(30 psig for a 6 to 30 psig signal range), move the

adjustor a small distance away from the pivot to

increase

span. Then repeat steps 4 through 9.

b. If output is

above

1.0 bar for a 0.2 to 1.0 bar

signal range (15 psig for a 3 to 15 psig signal

range) or 2.0 bar for a 0.4 to 2.0 bar signal range

(30 psig for a 6 to 30 psig signal range), move the

adjustor a small distance toward the pivot to

decrease

span. Then repeat steps 4 through 9.

Note

If the controller cannot be calibrated,

look for other problems as described

in the Troubleshooting section, such

as a nonperpendicular flapper-nozzle

condition, leaky connections, or a

binding displacer rod. If none of these

troubles is apparent, the displacer or

torque tube may be sized for a different

set of service conditions. Ensure that

the displacer is sized correctly for the

application.