Table 3.

Flow Coefficients

ORIFICE

NPS 1 / DN 25 BODY

NPS 2 / DN 50 BODY

In.

mm

Wide-Open C

g

for

External Relief Sizing

Wide-Open C

v

for

External Relief Sizing

C

1

Wide-Open C

g

for

External Relief Sizing

Wide-Open C

v

for

External Relief Sizing

C

1

9/16

14.3

211.6

5.6

37.8

219.3

6.0

36.0

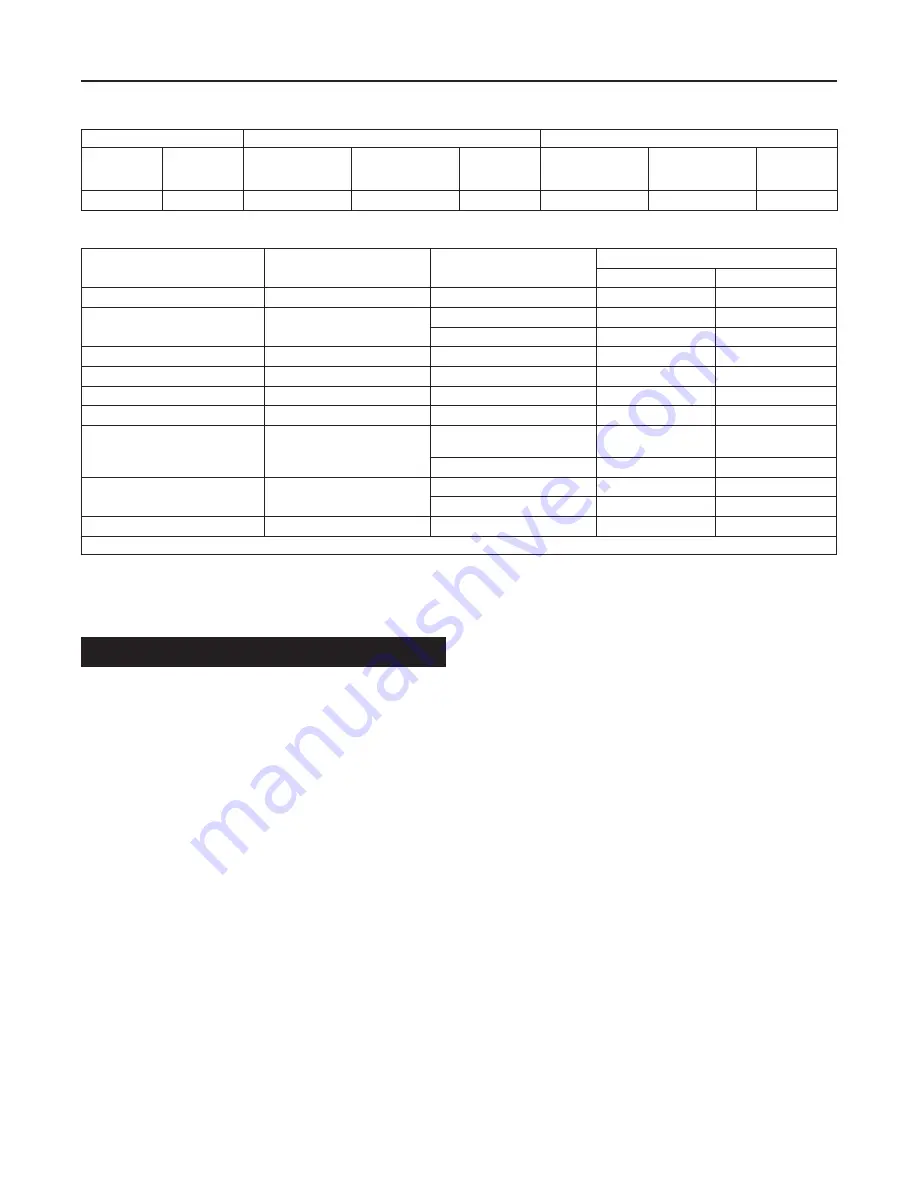

Table 4.

Maximum Torque Values

KEY NUMBER

(1)

COMPONENT

CONSTRUCTION

MAXIMUM TORQUE

Ft-lbs

N•m

2

Orifice

All

25 to 35

33.9 to 47.5

3

Cap screw, Body

Aluminum lower casing

10 to 20

13.6 to 27.1

Ductile Iron or Steel lower casing

22 to 30

29.8 to 40.7

9

Disk Holder Assembly

All

20 to 24 in-lbs

2.3 to 2.7

18

Cap screw, Lever

All

7 to 10

9.5 to 13.6

22

Nut, Diaphragm Connector

627BMR

15 to 20

20.3 to 27.1

26

Guide Retainer

627BMR

2.5 to 4

3.4 to 5.4

37

Cap screw, Spring Case

Ductile Iron or

Aluminum lower casing

7 to 10

9.5 to 13.6

Steel lower casing

36 to 40

48.8 to 54.2

46

Cap screw, Diaphragm Head

627BM

7 to 10

9.5 to 13.6

627BHM

12 to 16

16.3 to 21.7

78

Spring Seat Retainer

All

55 to 60 in-lbs

6.2 to 6.8

1. Refer to Figures 6 through 8 for key number locations.

Startup and Adjustment

Startup

▲

WARNING

To avoid personal injury or property damage

due to explosion or damage to regulator or

downstream components during startup,

release downstream pressure to prevent an

overpressure condition on the diaphragm of

the regulator.

In order to avoid an overpressure condition and

possible equipment damage, pressure gauges

should always be used to monitor pressures

during startup.

1. Slowly open the upstream shut-off valve.

2. Slowly open the downstream shut-off valve.

3. Check all connections for leaks.

4. Make final control spring adjustments according to the

adjustment procedures.

Adjustment

The range of allowable pressure settings is marked on the

nameplate. If a pressure setting beyond this range is necessary,

substitute the appropriate regulator control spring. Change the

nameplate to indicate the new pressure range.

Before increasing the setting, refer to Table 1 or 2. Review the

pressure limits for the control spring range being used and

be certain that the new pressure setting will not result in an

overpressure condition.

Note

Always use a pressure gauge to monitor

pressure when making adjustments.

Refer to Figures 6 through 8 for key number locations.

1. Remove the adjusting screw cap (key 36).

2. Loosen the locknut (key 34).

3. Increase the outlet pressure setting by turning the adjusting

screw (key 35) clockwise. Decrease the outlet pressure

setting by turning the adjusting screw counterclockwise.

4. When the desired pressure is obtained, hold the adjusting

screw (key 35) in place and tighten the locknut (key 34).

5

627B Series