10

C6.2.41/0219/E

NOTE: Since the discharge stub contains a check valve, care must be taken not to overheat

it to prevent brazing material from flowing into it.

3.3

Shut-off valves and adaptors

CAUTION

Leaking system! System breakdown!

It is strongly recommended to

periodically re-torque all pipe and fixing connections to the original setting after

the system has been put into operation.

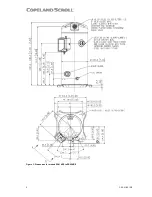

Figure 7

Copeland Scroll compressors ZR*KRE are delivered with a discharge check valve fitted inside the

discharge port and stub tubes as standard. There are options to fit Rotalock adaptors and Rotalock

valves.

Brazing connections can be converted to Rotalock by means of adaptors. Rotalock shut-off valves

are available for the suction as well as discharge sides. Using either straight or angled adaptors

provides a way to convert a Rotalock into a brazing connection.

Refer to the following table for proper tightening torques:

Torque [Nm]

Rotalock ¾"

– 16UNF

40-50

Rotalock 1"

– 14UNS

70-80

Rotalock 1 ¼"

– 12UNF

110-135

Rotalock 1 ¾"

– 12UNF

135-160

Rotalock 2 ¼"

– 12UNF

165-190

Table 4

NOTE: More information about adaptors and shut-off valves can be found in the spare parts

software at

www.climate.emerson.com/en-gb

.

3.4

Suction accumulators

CAUTION

Inadequate lubrication! Bearing destruction!

Minimise liquid refrigerant

returning to the compressor. Too much refrigerant dilutes the oil. Liquid

refrigerant can wash the oil off the bearings leading to overheating and bearing

failure.

Irrespective of system charge, oil dilution may occur if large amounts of liquid refrigerant

repeatedly flood back to the compressor during:

▪

normal off cycles;

▪

defrost;

▪

varying loads.