20

C6.2.24/1014-0215/E

Compressors ZBD58K* to ZBD114K* and ZFD41K5E:

These models have no internal

temperature protection and therefore require an external thermostat or a discharge temperature

sensor (NTC thermistor) mounted as close as possible to the discharge fitting in order for the

Digital Scroll controller to operate properly. For best response the sensor should be insulated.

Compressors ZFD13KVE to ZFD25KVE:

For low temperature applications with

R404A

, these

compressors could be used with the NTC thermistor, connected to the digital Scroll controller.

For low temperature applications with

R407A, R407F, R448A and R449A

the DTC valve bulb

(for the wet vapour injection system) must replace the existing NTC sensor located at the side of

the compressor top cap. Since there is no more connection possibility for the NTC sensor bulb,

the previous NTC sensor has to be removed and the controller, eg, ALCO EC3-D*, has to be

modified (disable discharge sensor input). A new discharge gas thermostat must be installed on

the discharge line. DO NOT use the previous solution NTC controller as a discharge

temperature protection since its rating is not suitable for R407A, R407F, R448A and R449A.

The R404A, R407A, R407F, R448A and R449A

dedicated discharge thermostat has a cut-out

setting of 130°C ± 4K with closing at 101°C ± 8K.

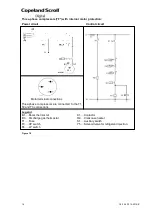

The thermostat should be installed approximately

120 mm from the discharge valve outlet (see

Figure 25

). It must be insulated in order to avoid

improper functioning due to false readings (see "X"

in

Figure 25

).

4.5 High potential testing

WARNING

Conductor cables! Electrical shock!

Shut off power supply before high-

potential testing.

CAUTION

Internal arcing! Motor destruction!

Do not carry out high-voltage or

insulation tests if the compressor housing is under vacuum.

Emerson Climate Technologies subjects all Scroll compressors to a high-voltage test after final

assembly. Each motor phase winding is tested, according to EN 0530 or VDE 0530 part 1, at a

differential voltage of 1000V plus twice the nominal voltage. Since high-voltage tests lead to

premature ageing of the winding insulation further additional tests of that nature are not

recommended.

If it has to be done for any reason, a lower voltage must be used. Disconnect all electronic

devices, eg, motor protection module, fan speed control, etc prior to testing.

Figure 22: Discharge temperature protection

recommended position

X