8

C6.2.24/1014-0215/E

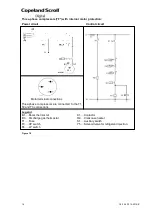

Mounting parts ZBD21K* to ZBD114K* & ZFD13K* to ZFD41K* - Soft mountings

Figure 6

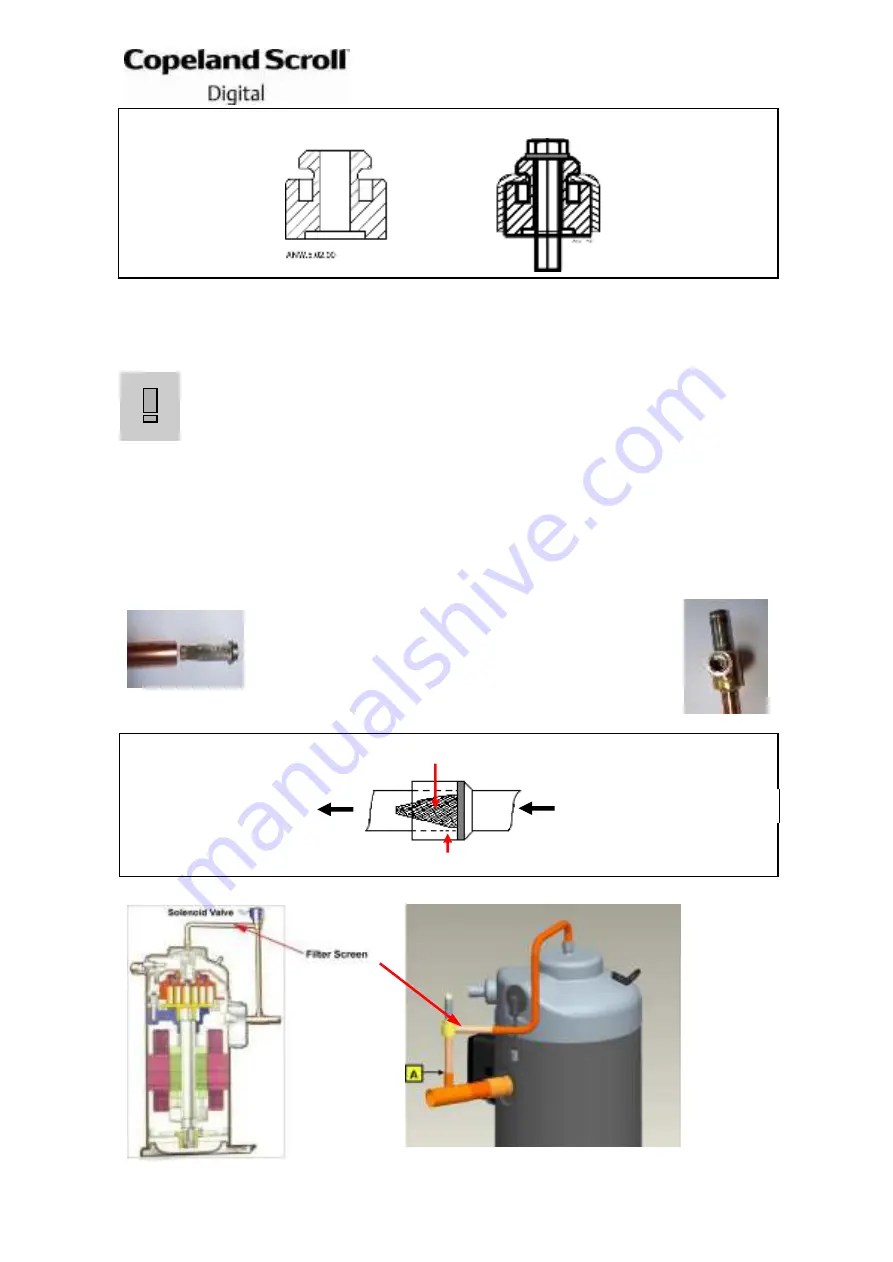

3.2 Solenoid valves for models ZBD21K* to ZBD57K* and ZFD13KVE to

ZFD25KVE

IMPORTANT

The external solenoid valve is a critical component for proper function of this

compressor.

Only

the Copeland brand solenoid valve supplied as a

requested accessory must be used.

Care must be taken during the brazing process that no solid parts can enter the control piston

compartment or the solenoid valve tubing. To prevent solid parts from entering the control valve

seat, the solenoid valve kit contains a filter screen, which has to be placed into the horizontal

tube of the valve before brazing the tube connections as shown in

Figure 10

below.

The solenoid valve has to be fitted in such a way that the sleeve with the stem inside

–

which

supports the solenoid coil

–

is fixed and aligned in the upright position.

3.2.1 Securing the filter screen in position

The filter screen should be placed into the small tube running

at 90° to the solenoid valve stem. A narrow washer fixed on

the filter screen will sit on the end of the tube preventing it

falling inside (see photos). The tube running from the top

centre of the compressor down to the previous tube needs to

be swaged at the solenoid valve end so that it covers the filter screen/tube and is

then brazed into position.

Filter screen with washer

To solenoid valve

end From top o From compressor

Swaged tube

Swaged tube

Figure 7

Figure 8: Position of external solenoid v alv e Figure 9: Recommended piping