Installation, Operation and Maintenance Manual

MAN-02-01-39-0704-EN Rev. 0

July 2019

Removal of Actuator from Valve

Section 8: Removal of Actuator from Valve

CAUTION

Do not attempt to remove mounting bolts between actuator and valve until supply pres

-

sure has been disconnected and vented. If spring return, be sure that valve is completely

in failed position. If valve is frozen in a position causing the spring to be cocked, removal of

bracket bolts would allow spring to stroke, resulting in the actuator rotating over bracket

causing possible injury or damage.

A.

Loosen bracket to actuator bolts to hand tight position.

B.

Physically shift actuator back and forth to be sure there is no strain (or shear

stress) on the bracket bolts. Once it has been determined that there is no pressure

or spring coil remaining in the actuator, remove bolts and remove actuator and

coupling from valve.

C.

In the event the valve is frozen or locked in place, resulting in spring energy

remaining in the actuator, replace adjusting screw (37) on end of actuator

opposite spring end with length of ‘all thread’ rod of sufficient length and turn

clockwise until it contacts the piston. This procedure will safely secure the piston

and spring assembly and allow actuator removal. Be sure to remove "all thread" rod

prior to actuator disassembly.

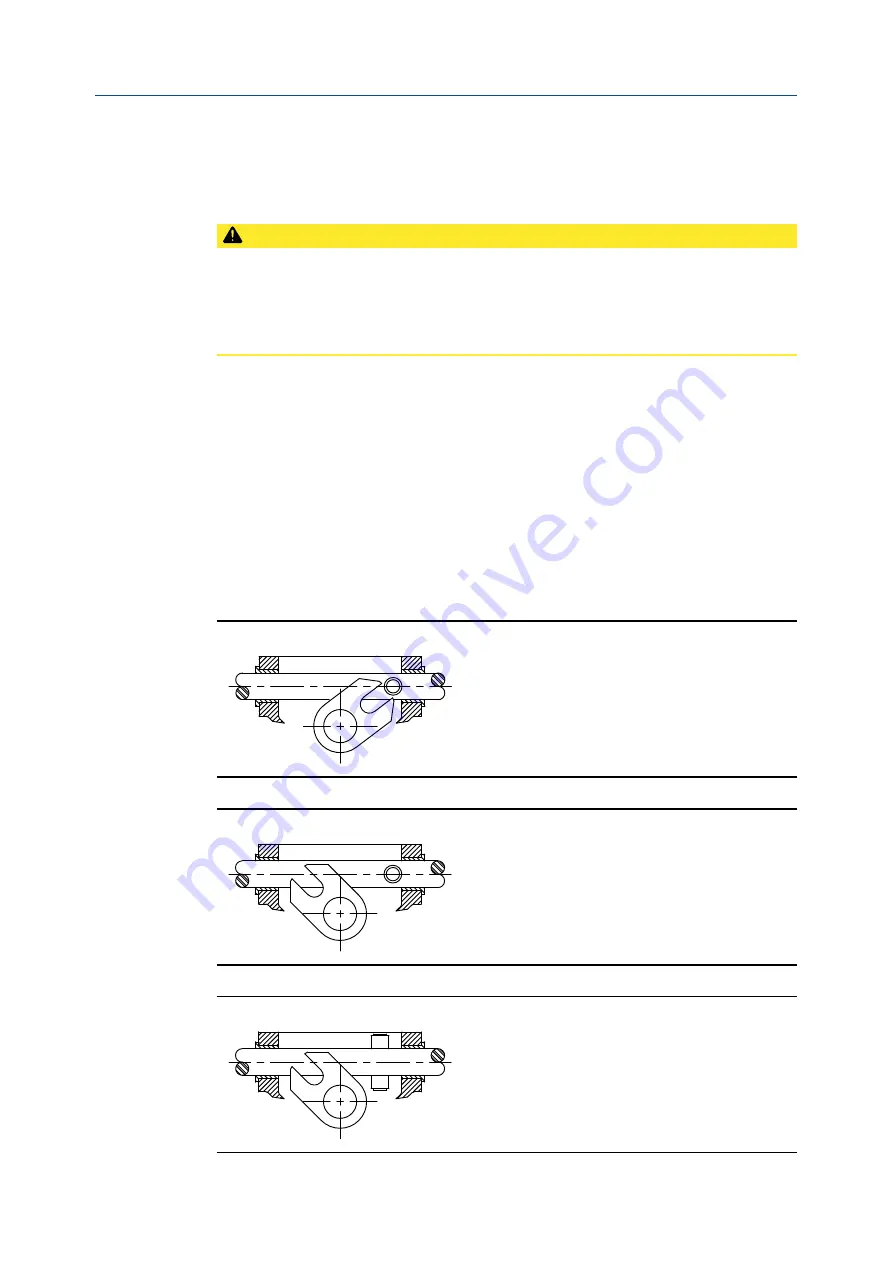

Figure 5

Figure 6

Figure 7

13

Section 8: Removal of Actuator from Valve

Содержание Bettis M Series

Страница 29: ......