Installation, Operation and Maintenance Manual

DOC.IOM.RG.US Rev. 11

November 2021

21

Section 11: Operator Disassembly

Operator Disassembly

3.

Connect flexible hoses to the ports of the cylinder to be repaired at the tee connection. Use

the handpump to cycle the operator to push the fluid out of the repair cylinder.

4.

Position the operator that the piston cap screw is against the end stop of the cylinder to

be repaired.

NOTE:

If necessary to remove all piping, fitting plugs/caps will need to be installed to prevent oil spills.

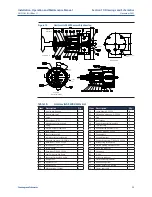

Cylinder disassembly

1.

Mark the cylinder parts for reinstallation on the same end and orientation of

the operator.

2.

Remove stay rod nuts and end cap (it is not necessary to remove end stop and cover if no

seal is replaced).

3.

Remove some stay rods for access to cylinder and piston.

4.

Slide cylinder back off piston.

5.

Remove piston cap screw, piston and seals.

6.

Remove cylinder plate ring, cylinder plate bolts and cylinder plate itself. Note the location

and number of seals.

7.

Remove drive rod seal (polypak) from cylinder plate.

NOTE:

There is no drive rod seal in the drive case, only a guide.

All pressure containing parts can now be inspected and replaced as necessary. It is a good practice

to replace all seals even if they appear serviceable. Proceed with cylinder assembly in Section 12,

unless complete disassembly is required.

Drive case disassembly

1.

Remove 10 cover cap screws and lift off the drive case cover.

2.

Remove tanks, allowing entry to access hole for lower snap ring removal

if necessary.

3.

Remove the 2 drive pin snap rings, drive pin and rollers. Lift lower roller for best access to

lower snap ring (Series 3 and Series 6 drive pin with its lower snap ring is removed through

the access hole in bottom of drive case).

4.

Slide the drive rod out of the drive case, careful to avoid damage to the drive

rod surface.

5.

Lift out the yoke, upper and lower bushings, and bearings. Upper bushing may lift off with

the cover.

6.

Clean and inspect all parts; replace if necessary.