INSTALLATION

(continued)

1--3

Install the Transfer Switch

After the enclosure is installed and power cables or bus

connected to the Bypass Switch, the Transfer Switch

carriage can be rolled in. The floor of the cabinet must be

free of debris and clean. If necessary, use a vacuum cleaner.

Make a thorough inspection to be sure no tools are left

inside. The Bypass Handle must be in the

BYPASS POS

position (closed on normal). The Isolation Handle (draw-

out crank) must be fully counterclockwise against stop.

Do not apply any electrical power to the ATB yet.

It is not necessary to remove the barriers from the bypass

switch and transfer switch. If you do remove them,

however, reinstall them carefully.

NOTE

: Be sure to roll the correct Transfer

Switch into the enclosure. If more than one is

supplied, each will be labeled above the

solenoid operator.

The Transfer Switch

NORMAL

contacts must be closed.

If not, use the manual operator handle (maintenance

handle stored on lower carriage) to manually operate the

switch. See Figure 1–10. Check that all arc chutes and

interphase barriers are in place on the Transfer Switch.

Then grasp the Transfer Switch carriage frame and roll it

into the cabinet (isolation contacts facing inward). Align

the rollers between the floor guides and push the carriage

in until its crank pins engage the latch plates on both

sides. Then follow the procedure below:

NOTE

: Solenoid lock

SL1

on the Isolation

shaft inhibits operation of the drawout (Isola-

tion contacts) unless the Transfer Switch and

Bypass Switch are in compatible positions.

This solenoid must energize to unlock. Be-

cause all power sources are de-energized, the

interference tag defeats the solenoid in the

following inspections.

Do the three inspections on page 1-4 without any

electrical power connected. The inspections will verify

that the isolation contacts are in proper alignment. If

necessary, add shims under the floor. It may be helpful to

remove the the right side of the enclosure to expose the

isolation contacts during the inspections.

Do not apply any power to the Bypass Switch.

Be sure that the Normal and Emergency source

circuit breakers are OPEN before proceeding.

!

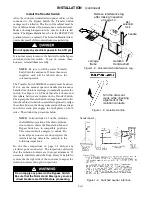

SL1

solenoid

lock

Remove interference tag

after making inspection

on page 1-4.

Isolation

Handle shaft

carriage

frame

handle

Figure1–2. Solenoid latch interference tag.

Turn the draw-out

crank while checking

alignment of the

isolation contacts.

Figure 1–3. Isolation Handle.

Transfer Switch

NOMINAL CONTACT GAP 1/8” WHEN OPEN.

Figure 1–4. Switched neutral interlock.