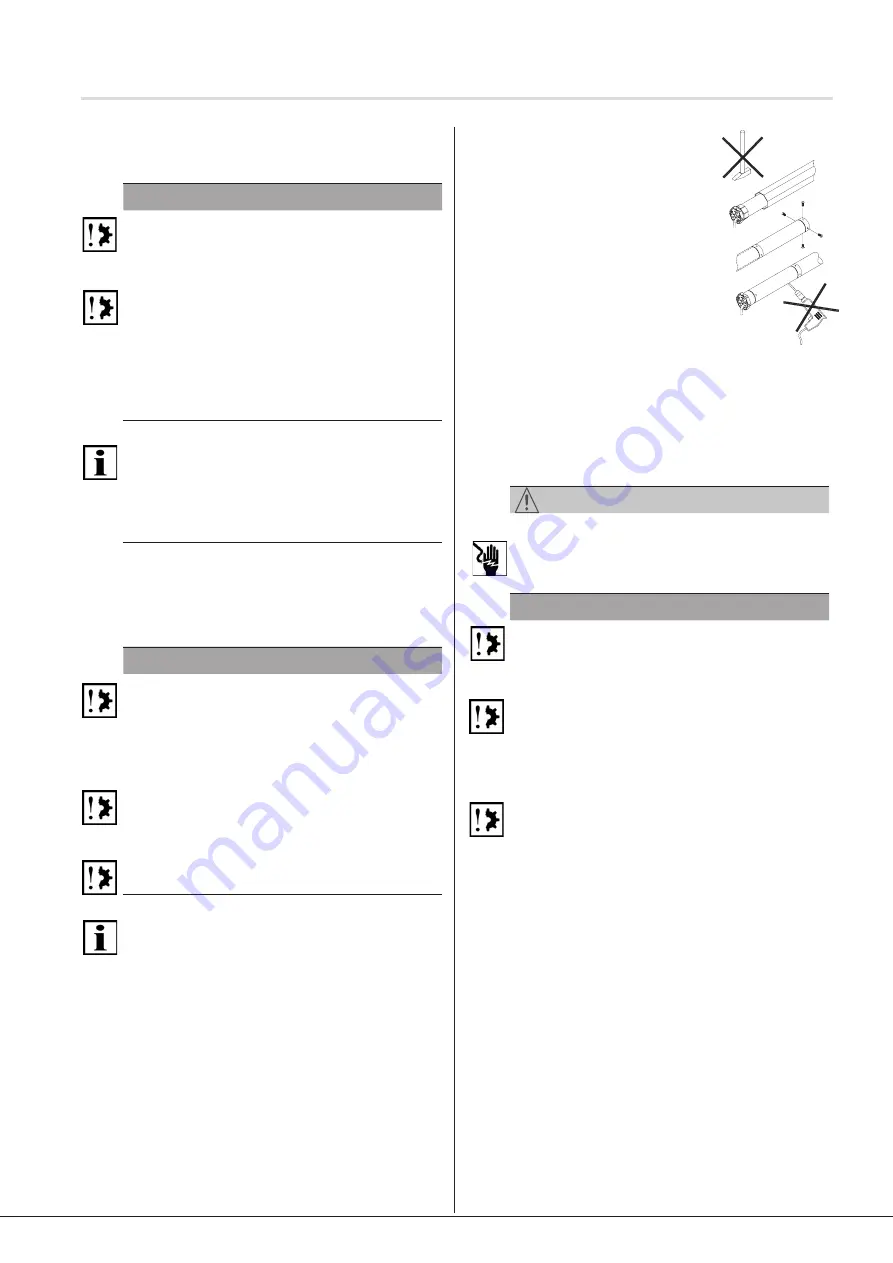

Installation in profile tubes

Ⓐ

Push drive with relevant adapter and

crown into the profile tube.

Install the motor cable so it is protected

to prevent damage from the driven

part.

Ⓑ

Secure the counterpart support to

prevent axial movement, e.g. screw

or rivet on the idler. Secure the drive

axially in the support!

ⒸAttach the blind to the shaft.

The drive is fastened on the wall anchor and the blind

mounted on the shaft using the suitable motor bearings and

adapter components according to building requirements

and, depending on the type of blind, with suitable connection

elements, also provided by the system supplier.

Only operate the drive horizontally, as intended, with the

connection cable leading out from the side and away from the

slat movement area.

5.2 Electrical connection

WARNING

Faulty electrical connections constitute a fatal hazard.

Risk of electric shock.

►

Prior to initial commissioning, check the PE wire is correctly

connected.

ATTENTION

Damage to the InDrive M30/1.6 RH due to incorrect electrical

connection.

►

Prior to initial commissioning, check the PE wire is correctly

connected.

Damage to or destruction of the InDrive M30/1.6 RH due to

the penetration of moisture.

►

For devices with protection class IP 44, the customer-side

connection of the cable ends or plugs (cable feed-through)

can also be implemented according to protection class

IP 44.

Damage to or destruction of the InDrive M30/1.6 RH for

variants with 230 V 1 AC due to incorrect activation.

►

Switches for drives that are set to OFF by default (dead-

man's switches) are to be installed within visible range of the

InDrive M30/1.6 RH, but away from moving parts and at a

height of more than 1.5 m.

4 | EN

©

elero

GmbH

Assembly (electrical connection)

Drive is overwound and may destroy parts of the application.

►

For safe operation, the end positions must be set/taught in.

►

Manufacturer training is available for specialist companies.

ATTENTION

Power failures, breaking of machine parts and other

malfunctions.

►

For safe operation, assembly must be correct and the end

positions must be configured upon commissioning.

Damage to InDrive M30/1.6 RH due to the penetration of

moisture.

►

On devices with protection class IP 44, the ends of all

cables or plugs will need to be protected from ingress of

moisture. This measure must be implemented immediately

after removing the InDrive M30/1.6 RH from the original

packaging.

►

The drive must be installed so that it cannot get wet.

Important

In its delivery state (factory setting), the InDrive M30/1.6 RH

will be in commissioning mode.

►The end positions will need to be configured

(see section 5.6).

5.1 Mechanical fastening

Important preliminary consideration:

The working area around the installed drive is usually very

small. For this reason, obtain an overview of how the electrical

connection has been implemented prior to the mechanical

installation (see section 5.2) and make the necessary changes

beforehand.

ATTENTION

Crushing or tension will damage the electrical cables.

►

Install all electrical cabling so that it is not subject to any

crushing or tensile load

►

Observe the bending radii of cables (at minimum 50 mm).

►

Route connecting cables in a downward loop to prevent

water running into the drive.

Damage to the drive due to the effect of impact forces.

►

Slide the drive into the shaft. Never knock the drive in or use

force!

►

Take care not to drop the drive!

Damage or destruction to the drive by drilling.

►

Never drill the drive!

Important

Only secure the InDrive M30/1.6 RH using the fastening

elements provided for this purpose.

Fixed installed control devices need to be attached so they are

visible.

•

The profile tube must have sufficient clearance from the

motor tube.

•

Make sure there is sufficient axial play (1 - 2 mm)