Range installations steps

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

G

Carefully slide range into cabinet opening while inserting

rear leveling leg into and FULLY ENGAGING THE ANTI-TIP

BRACKET (See Fig. 26). Make sure that the flexible

appliance conduit (Fig. 18) and the power cord (Fig. 20)

folds into the remaining open floor area behind the range

warmer or storage drawer.

Make sure that the flexible

appliance conduit does not become pinched or kinked!

Pre-shape the flexible appliance conduit and power cord if

necessary to insure that the range slides into cabinet

opening properly. Be sure to check level of the range by

placing a level horizontally on an oven rack (See Fig. 27).

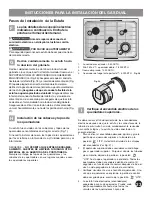

Surface burner heads, cap & grates.

H

It is very important to make sure that all of the surface

burner heads, surface burner caps and surface burner

grates are installed correctly.

Your appliance was shipped with the burner heads and

burner caps assembled in the correct locations (Fig. 38).

Should you need to re-install the burner caps please refer

to the Use & Care guide for more information.

REMEMBER —

DO NOT ALLOW SPILLS, FOOD,

CLEANING AGENTS OR ANY OTHER MATERIAL TO

ENTER THE

GAS ORIFICE HOLDER OPENING.

Always keep the Burner

Caps and Burner Heads in place whenever the surface

burners are in use.

I

Carefully slide range into cabinet

opening.

If burner goes out, reset control to OFF.

Remove the burner control knob.

Use a thin-bladed screwdriver and adjust the inner burner

flame size with the right-hand set screw (See Fig. 40).

Adjust the outer burner flame size with the lower set screw

(See Fig. 40). Turn counterclockwise to increase flame size.

Turn clockwise to decrease flame size.

Test to verify if “LO or LOW” setting should be adjusted

(right front position ONLY)

1.

Push in and turn knob to (lite) until burner ignites.

2.

Push in and quickly turn knob to LOWEST POSITION.

3. If burner goes out, reset control to OFF.

4.

Remove the burner control knob.

5.

Use a thin-bladed screwdriver and adjust the inner

burner flame size with the right-hand set screw (See Fig.

J

Adjust the "LO" setting of surface

burner valve (for linear flow valves

only).

40). Adjust the outer burner flame size with the lower

set screw (See Fig. 40). Turn counterclockwise to

increase flame size. Turn clockwise to decrease

flame size.

Check electric ignition of surface burners.

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

1.

To check for proper lighting,

push in and turn

surface

burner knob

counterclockwise

to the

(lite) position.

You will hear the igniter sparking ( Fig. 39).

2.

The surface burner should light when gas is available

to the top burner. Purge air from supply lines by

leaving knob in the

(lite) position until burner ignites.

Each burner should light within four (4) seconds in

normal operation after air has been purged from supply

lines.

3.

Visually check that the burner has lit. Once the burner

lites, turn the control knob out of the

(lite) position.

4.

The range has separate electrodes (igniters) for each

burner. Try each knob separately until all burner valves

have been checked.

Fig. 38

1.

2 Standard burners - 9,500 BTU.

2.

Min-2-Max™ - double burner - 18,000 BTU.

3. Large burner - 14,000 BTU.

4.

Perfect Simmer burner™- 5,000 BTU

Fig. 39

11

1

2

3

4

1