17

ENGLISH

Fig.3.5.3-2

NOTE:

• The wiring diagram as shown just

for reference only, please refer to the

label stickerd on the unit for correct

connection.

After confirming the above conditions,

prepare the wiring as follows:

• The screws which fasten the wiring

to the terminal block may come loose

from vibrations during transportation.

• Check and make sure all screws are

well fixed.

•

Be sure the circuit capacity is sufficient.

• Ensure the starting voltage is

maintained at over 90% of the rated

voltage marked on the nameplate.

•

Confirm that the cable thickness is

as specified in the power source

specification.

• Always install a Residual Current Device

(RCD) in wet or moist area.

• The following may be caused by

voltage drop: Vibration of a contactor,

which will damage the contact point,

fuse blowing, disturbance of the normal

function of the overload.

• The means for disconnection from a

power supply shall be incorporated in

the fixed wiring and have an air gap

contact separation of at least 3mm in

each active (phase) conductor.

3.6

Air Purging and Leakage

Test

Air and moisture in the refrigeration system

have undesirable effects as indicated

below:

• Pressure in the system rises.

• Operating current rises.

• Cooling or heating (only for models with

heating function) efficiency drops.

• Moisture in the refrigerant circuit may

freeze and block capillary tubing.

• Water may lead to corrosion of parts in

the refrigeration system.

Therefore, the indoor unit and tubing

between the indoor and outdoor unit must

apply leakage test and be evacuated

to remove any noncondensables and

moisture from the system.

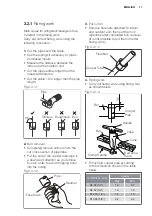

3.6.1

Air Purging With Vacuum

Pump

1.

Check that each tube (both liquid and

gas side tubes) between the indoor

and outdoor units have been properly

connected and all wiring for the test

run has been completed. Remove the

service valve caps from both the gas

and the liquid side on the outdoor unit.

Note that both the liquid and the gas

side service valves on the outdoor unit

are kept closed at this stage.

2.

When relocating the unit to another

place, perform evacuation using

vacuum pump.

3.

Make sure the refrigerant added into

the air conditioner is in liquid form in

any case.

4.

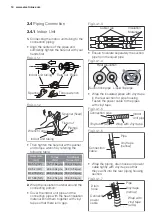

Except for inverter model, Systems

having the outdoor unit mounted

above the indoor unit (e.g. basement

installations) have the following

additional requirement: For systems

with elevation of 7.5m refrigerant lines

must be oil trapped between 2.5m

and 5m of elevation. For systems

with elevation of greater than 7.5m,

refrigerant lines must be oil trapped at

least every 5m of elevation. (no oil trap

Magnetic ring

(If supplied and

packed with the

accessories)

Содержание ESM09CRR-B3

Страница 24: ...www electrolux com shop 91030a ...