43

05/2005 - Art. Nr. 13 018 106A

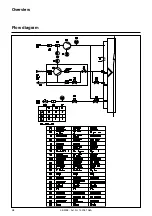

Type

Burner

power

kW

Öl flow

kg/h

Nozzle

Gph

Pump pressure

bar

Dimension

Y

mm

Air flap setting

1. load

2.load

1. load

2.load

Ignition load

Gas

Cam III

Low load

Oil

Cam VI

High load

Oil + Gas

Cam I

V-GL

05.700

DUO

PLUS

350

29,5

4,5

3,75

14

13

10

0°

4°

28°

450

37,8

4,5

5

17

18,5

20

0°

6°

30°

500

42

4,5

6

16,5

15

20

0°

6°

35°

600

50,6

4,5

7,5

18

15,5

25

0°

9°

45°

700

59

4,5

10

18

17

35

0°

12°

55°

V-GL

05.1000

DUO

PLUS

500

43,5

4,5

4,5

20,5

23,5

10

10°

7°

34°

600

50,5

5,0

6,0

17,5

17,5

20

10°

8°

40°

700

59

5,0

8,5

17,5

17

30

10°

8°

48°

1000

84,4

5,0

11

22

24

40

10°

10°

90°

1 kg Oil at 10°C = 11,86 kWh

The above setting data are

basic settings

. The factory setting data are in boxes with thick black borders. The burner can

normally be run using these settings. Check the setting values carefully in each case. System-specific corrections may be

necessary.

Good combustion values can be achieved using

Danfoss 45°B (recommended)

nozzles

Equivalent nozzles: Delavan 45°A, Steinen 60°SS, Danfoss 60°B (for Stage 1).

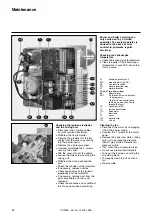

Gas pressure switch

·

Remove the transparent cover.

To set, use the rotating scale and

x

marker.

·

Provisionally set to the minimum

value on the scale.

Air pressure switch

·

The device contains a movable disk

with a scale and a

x

marker.

·

Provisionally set the air pressure

switch to the minimum value on the

disk.

Start-up

Setting data

Setting the burner head

Initial setting of gas pressure switch and air pressure switch

Setting the burner head

The burner head setting (dimension Y)

should be set for the appropriate burner

power using the above table. To adjust

the setting, turn screw

V

. Start-up

behaviour, pulsations and combustion

values can be improved via the burner

head setting. If the Y value is reduced

on the scale, the CO

2

value increases

but start-up behaviour (ignition) is

rougher.

EN