Mechanical Operation and Maintenance Manual for ER180-4-3200 Industrial Robot

27

4.3 Inspection of the Lubricant

Inspect the iron powder concentration in the lubricant every 10000 hours or every 2 years. Replace the

lubricant or decelerator if the concentration exceeds 0.1%Wt. Please contact the service department when

in need.

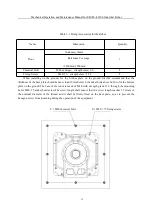

Tools Needed

No.

Specifications

Remarks

1

OM-810 iron powder concentration meter

Manufactured by Idemitsu Kosan

2

Filling gun

The nozzle diameter should be less than 17mm and

should be equipped with a counting device.

3

Sealing tapes

/

Attention

In inspection, please supply with the filling gun if a certain amount of lubricant has

flowed out of the robot. The nozzle diameter should be less than 17 mm. The

lubricant supplied should not exceed the designated amount limit.

Attention

After inspection or refilling, please seal the pipe connection with sealing tapes. The

filling gun equipped with a counting device is recommended. Please check the

lubricant amount changes after refilling to ensure that it is within the designated

amount limit.

Attention

The inner pressure of the decelerator rises dramatically right after the

robot is stopped and the lubricant might squirt out once the inspection

screw is untightened. Lubricant should be refilled when the air pressure of

the decelerator is gradually released.

Attention

The lubricant should be constantly inspected to ensure its working

proficiency.

4.4 Change the Lubricant

4.4.1 The Oil Supply Quantity of Lubricant

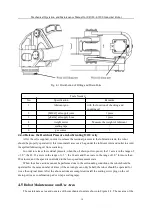

Table 4-6 Oil Supply Table of Changing the Lubricant

Position

Amount

Name for the lubricant

Remarks

J1 axis decelerator

4500cc

MOLYWHITERE No.00

Rapid oiling will cause the pressure

in the oil tank to rise, the crack of

sealing ring, and the leakage of

lubricating oil . The oil supply speed

should be controlled below 40cc/10

seconds.

J2 axis decelerator

1100cc

J3 axis decelerator

1100cc

Component 1 of J3 axis

160cc

Component 2 of J3 axis

170cc

Wrist component

250cc