A652–07–880

Issue D Original

Instruction Manual

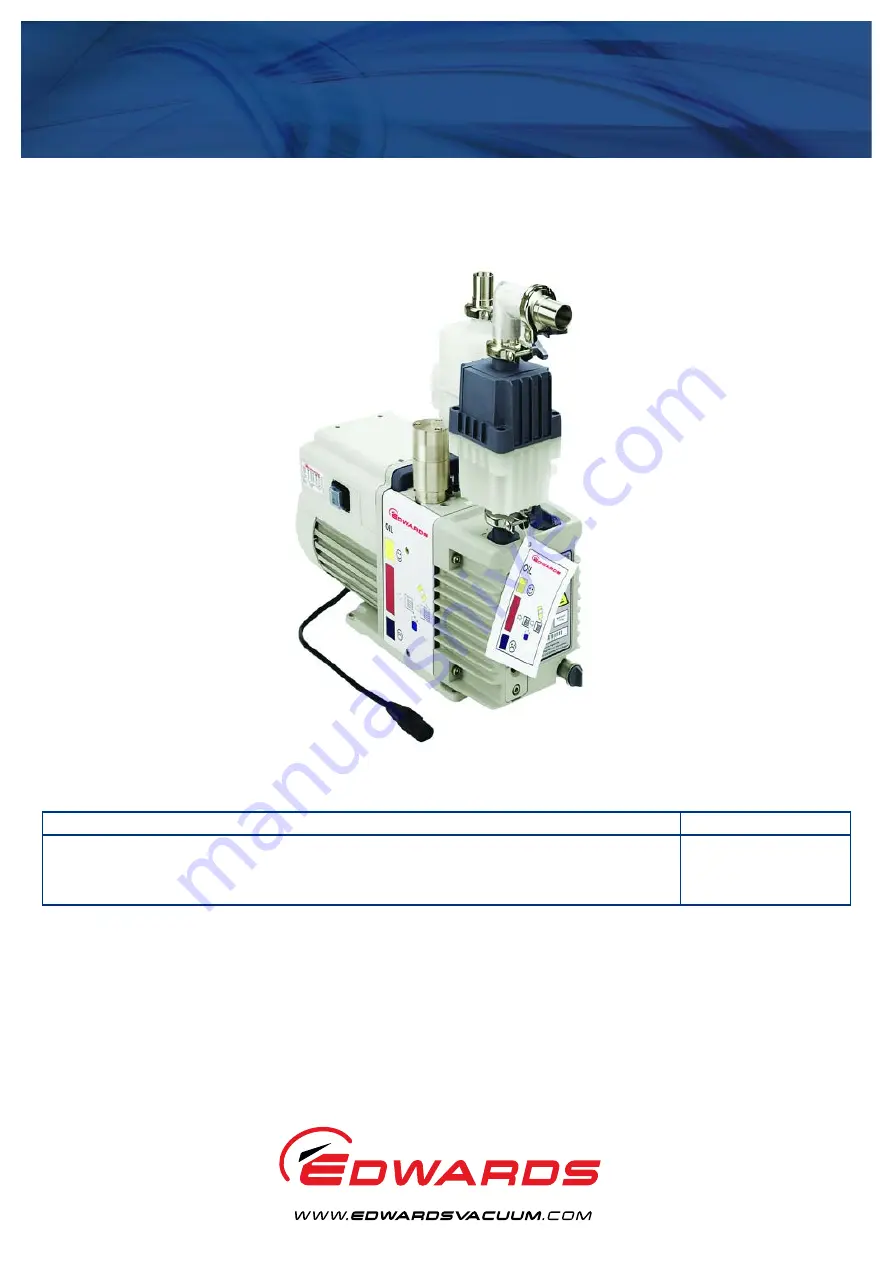

E-LAB 2 Pumps

Description

Item Number

E-LAB 2 Pump, 110-120/220-240 V, 50/60 Hz, single phase

A652-07-903

E-LAB 2 Pump, 100/200 V, 50/60 Hz, single phase

A652-07-904

E-LAB 2 Pump, 110-120 V, 50/60 Hz, single phase

A652-07-906