Introduction - General information

Persons operating the bale wrapper should absolutely consult the instruction manual and should have a

knowledge of OCCUPATIONAL SAFETY and HEALTH in the use of agricultural machinery;

The Bale wrapper is shipped with the operating instructions and warranty card in the complete state, any

unauthorized or willful changes in the design will cause the loss of it’s warranty;

The service and maintenance of the bale wrapper incompatible with this instruction manual releases the

manufacturer from liability for consequences resulting from its improper use and causes the warranty to be null

and void. The manufacturer reserves the right to make changes in the design of the machine not shown in this

manual and it’s description and intended use of machine and the basic technical data of this machine.

The bale wrapper, EW-450

A

, is a simple-to-use machine with a hydraulic drive. It’s intended use is for

the wrapping of individual bales of pre-dried hay from grasses and leguminous fodder plants with stretch film.

Plants intended for bales for silage should be mowed in the initial phase of earing. After a dozen or so hours of

pre-drying, the hay should be collected using the roll baler in a way that ensures maximum density with the

smallest amount of air in the middle of the bale. After the rolling of the bales, they should be wrapped as soon

as possible on the bale wrapper. The bales left unwrapped for long periods of time may be caused to resist the

putrefactive processes.

Bale wrapping with the film (foil), protects the mixture for ensilage before the long exposure to air, light

and moisture, creates favourable conditions for fermentation process. After wrapping, you must stack bales

in a maximum of two layers in a dry place on level ground. Particular attention should be paid to avoid

possible damage to the film. The damaged areas should be repaired in such a way as to ensure the continuity

of the layer. After approximately 6 to 8 weeks of storage at ideal temperatures, The haylage is then suitable for

the feeding of animals with the feed having reached it’s maximum nurishment level.

Содержание EW-450A

Страница 1: ...Operator s Manual Rev 05 22 Stationary Bale Wrapper EW 450A...

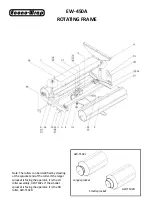

Страница 13: ...Parts Breakdown...

Страница 16: ...EW 450A LOWER FRAME...

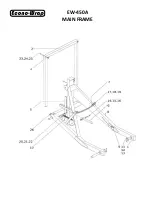

Страница 18: ...EW 450A MAIN FRAME...

Страница 20: ...EW 450A FILM FEEDER...

Страница 22: ......