After making sure that the inclusion of the drive does not endanger the surroundings, can start wrapping

including hydraulic drive from the tractor cab. When wrapping, the tractor engine must maintain approximately

1500 rpm. Bale wrapping should occur after 24 (film 20” setting) or after 16 (film 30” settomg) rotations of

rotating frame (after about 1 minute of the wrapping). Fully wrapped the bale should have two layers of film, what

provides a fully leak-proof protection before the access of air and water. After wrapping, one should stop the

machine at the time when rotating frame with drums is in perpendicular position to the axle of the tractor and

the direction of travel. After unlocking the locking pin and lifting of bale wrapper on Three Point Hitch of tractor,

will occur the tilting of the lower frame and self-acting unloading the bale. Do not cut off the film prior to loading.

For the purpose of loading the next bale, one should lower of bale wrapper and lock the lower frame with the

locking pin. The drums must be set in the position as for first loading.

Recommendations for use

During operation of bale wrapper, special attention shall be paid to the technical condition and tension of

driving chains. After starting a new bale wrapper and after wrapping approx. the ten of bales, check tension

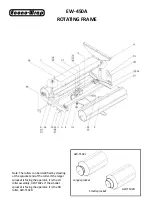

of driving chains, in particular of driving chain of rotating frame. To carry out the adjustment of the driving

chain of rotating frame, A)Remove Center Table Guard, B)Remove Gear Covers C) Rotate Bale Tray 90

degrees and D) Remove Front Frame Guard.

Once the chains are exposed, loosen the four nuts M12 (1) of the base of the hydraulic motor. Then, after

loosening the counter nut (2) screw in the bolt of chain tension (3) so that the deflection in the middle of the

longest segment of chain had about 20 mm.

After

the adjustment and control/inspection of the technical

condition,

lubricate

the

chain with oil for driving chains.

Содержание EW-450A

Страница 1: ...Operator s Manual Rev 05 22 Stationary Bale Wrapper EW 450A...

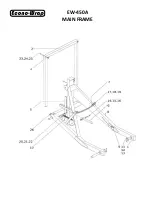

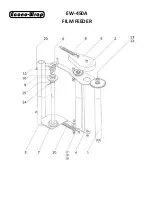

Страница 13: ...Parts Breakdown...

Страница 16: ...EW 450A LOWER FRAME...

Страница 18: ...EW 450A MAIN FRAME...

Страница 20: ...EW 450A FILM FEEDER...

Страница 22: ......