7

Maintenance and Spare parts

7.1

Maintenance

Personnel:

n

Mechanic

n

Qualified electrician

n

Specialist

n

Servicing personnel

NOTICE!

Only original spare parts may be used for maintenance and repairs.

CAUTION!

Dosing pumps may only be serviced by qualified and authorised persons.

DANGER!

Before maintenance, repair or replacement of parts / modules, disconnect the

pump from all voltage sources or disconnect the higher-level control unit from

the power supply and secure it against unintentional restarting.

DANGER!

– Legal regulations and the applicable product data sheets must be taken

into account for all chemicals.

– Personal protective equipment (PPE) should be worn during maintenance

work.

– Clean equipment with a damp cloth only (mild soap if necessary).

Do not splash or hose down the pump!

– No splash water or respectively do not spray the pump!

Maintenance interval at least every 3 months

Recommended inspections:

1.

Check suction and pressure line for a tight, leak-free connection.

2.

Check suction and pressure valve for contamination and seal tightness.

Chapter 5.2.1 ‘Connection: Suction and Pressure Lines’ on page 27

3.

Check for correct output rate setting.

4.

Check mounting screws on pump head (tight fit, 3.75 Nm).

Chapter 6 ‘Start-up Operations’ on page 30

Maintenance and Spare parts

35

Rev. 5-06.2018

Содержание 106052

Страница 2: ......

Страница 3: ...Membran Dosierpumpe Turbo SMART II Betriebsanleitung 417102229 EcoAdd Rev 5 06 2018 26 06 2018 GERMAN...

Страница 36: ...Kennlinien Das Potentiometer hat eine progressive Kennlinie Abb 10 Kennlinien Inbetriebnahme 34 Rev 5 06 2018...

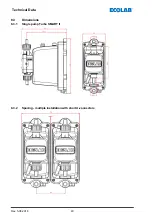

Страница 43: ...8 3 3 Abst nde Mehrfach Installation lange U Verbinder Technische Daten 41 Rev 5 06 2018...

Страница 54: ......

Страница 56: ...Diaphragm Dosing Pump Turbo SMART II Operating instructions 417102229 EcoAdd Rev 5 06 2018 26 06 2018 ENGLISH...

Страница 96: ...8 3 3 Spacing multiple installation with long U connectors Technical Data 41 Rev 5 06 2018...

Страница 107: ......