6

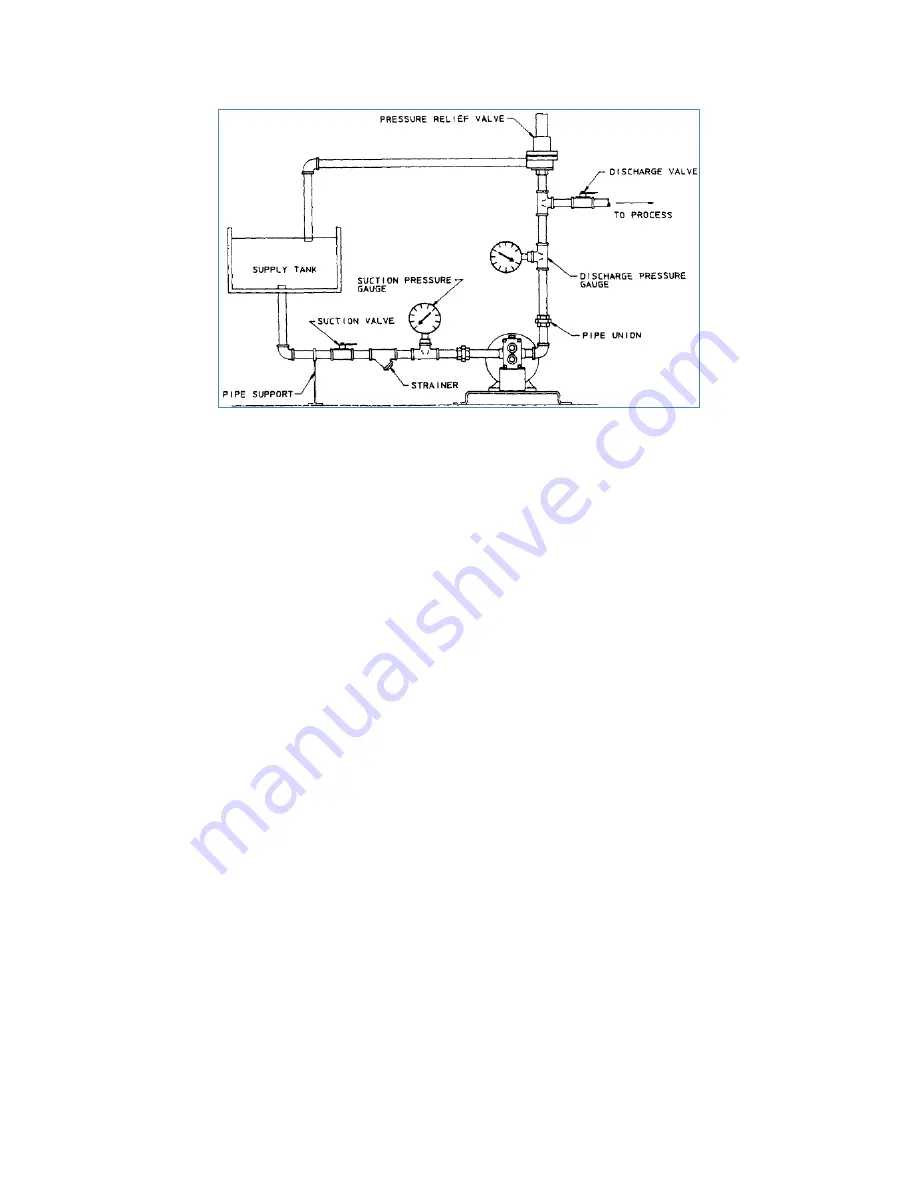

Figure 1

3. INSTALLATION

1. Pump installation site should be selected to provide easy access for routine

maintenance and to protect the pump from damage by the elements or from leaks or

drips from nearby process equipment.

2. Suction and discharge ports of Eco Gearchem pumps can be determined as follows:

A. Looking at the pump drive shaft, the suction port is to the right of the shaft,

when the shaft rotates clockwise and the drive shaft is located below

the ports for standard configuration on Model G2, G4, G6, GB and GHB.

B. Looking at the pump drive shaft, the suction port is to the left of the shaft, when

the shaft rotates clockwise, and the drive shaft is located above the ports for

standard configuration on Models GA 12 and GA 16.

C. Reversing drive shaft rotation reverses flow and thus suction and discharge ports

for all models.

3. Keep suction lines short, straight and of sufficient size to minimize friction loss to the

pump. Make sure there is sufficient suction supply, so that pump will not starve or

run dry. Flooded suction or gravity feed of fluid to pump inlet is generally preferred.

4. Use only full-bore ball valves or gate valves in the suction piping. If suction strainers

are required, size them to minimize pressure drop and select those of a type that are

easily cleaned.

5. Arrange all suction piping and fittings to prevent formation of air pockets. Make sure

all joints are tight.

6. Flush and blow out all suction lines prior to mating up to pump. Use nipples and

unions, or spool pieces with flanged pumps, for ease of maintenance.

7. Do not spring piping, either suction or discharge, when mating up to pump. Use

supports or hangars at intervals as required. When necessary, provide for thermal

expansion and contraction so that no strain is placed upon the pump.

8. Check carefully alignment of pump and motor or drive system. Improper alignment is

one of the most common causes of seal and stuffing box problems, as well as a

major cause of rapid bearing wear and eventual pump failure.

9. Check all bolts and nuts for tightness. Correct any conditions which could cause

destructive vibration or leakage.

10. Where required, provide proper system for seal flush, and/or drain. Observe any

special instructions for packing lubrication.

11. If start-up screens are used be sure they do not clog and starve suction. Start-up

screens should be removed prior to placing system into regular operation.

Содержание GA Series

Страница 1: ...ECO GEARCHEM PUMPS GA GC SERIES Installation Operation Maintenance Manual Bulletin IOM ECO 3000 REV C...

Страница 18: ...18 8 PUMP SPECIFICATION CHART...

Страница 19: ...19 9 EXPLODED VIEW DRAWING G2 G4 SERIES...

Страница 20: ...20 10 EXPLODED VIEW DRAWING G6 G8 SERIES...

Страница 21: ...21 11 EXPLODED VIEW DRAWING GH8 SERIES...

Страница 22: ...22 12 EXPLODED VIEW DRAWING GA12 GA16 SERIES...

Страница 23: ...23 13 SEAL ARRANGEMENT DRAWINGS...

Страница 24: ...24...

Страница 25: ...25...

Страница 26: ...26...

Страница 27: ...27...

Страница 29: ...29 15 GEARCHEM PUMP PRESSURES...

Страница 30: ...30...

Страница 32: ...32...

Страница 33: ...33...

Страница 35: ...35 15 PUMP PERFORMANCE CURVES...

Страница 36: ...36...

Страница 37: ...37...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 41: ...41...

Страница 42: ...42...

Страница 43: ...43...

Страница 44: ...44...

Страница 45: ...45...

Страница 46: ...46...

Страница 47: ...47...

Страница 48: ...48...

Страница 49: ...49...

Страница 50: ...50...

Страница 51: ...51...

Страница 52: ...52...

Страница 53: ...53...

Страница 54: ...54...

Страница 55: ...55...

Страница 56: ...56...

Страница 57: ...57...

Страница 58: ...58...

Страница 59: ...59 Pulsafeeder Inc 2883 Brighton Henrietta Town Line Road Rochester NY 14623 1 585 292 8000 www pulsa com...