Eclipse Extern-A-Therm Recuperators, Design Guide 540, 3/9/2009

6

Design

Furnace Temperature Limits

Up to 1800°F -

No special safeguards are required to

protect the recuperator. See “Special Precautions for

Aluminum Melting or Holding” on this page, for aluminum

applications.

1800°F - 2100°F -

To ensure that the safe operating

temperature of the recuperator tubes is not exceeded, air

flow must not fall below the following limits:

• Model 300 MA - 90 scfh

• Model 600 MA - 180 scfh

• Model 1500 MA - 450 scfh

• Model 2500 MA - 750 scfh

The recuperator must be positioned so that it will not be

exposed to direct radiation from the furnace. This is to

protect the recuperator during shut down or power failure.

Ŷ

When shutting a process down, air must be

supplied to the exchanger until the exhaust inlet

temperature falls below 1800°F.

2100°F - 2400°F -

Dilution air must be introduced to the air

stream to maintain exhaust temperature below 2100°F.

(See Figure 3.4.) The amount of dilution air can be

determined from the “Dilution Air” section, page 7. When

using dilution air do not operate with excess fuel, either

gas or oil. The resulting fire would destroy the recuperator.

A high temperature protection limit switch must be fitted to

ensure flue temperatures do not exceed 2100°F.

The recuperator must be positioned so that it will not be

exposed to direct radiation from the furnace. This is to

protect the recuperator during shutdown or power failure.

The low flow air requirements listed above must be

observed.

Ŷ

When shutting a process down, air must be

supplied to the exchanger until the exhaust inlet

temperature falls below 1800°F.

Flue Gas Restrictions

The recuperator must not be used with any chloride,

sulfide, potassium, sodium or lithium salts in the flue gas.

Special Precautions for Aluminum Melting or

Holding

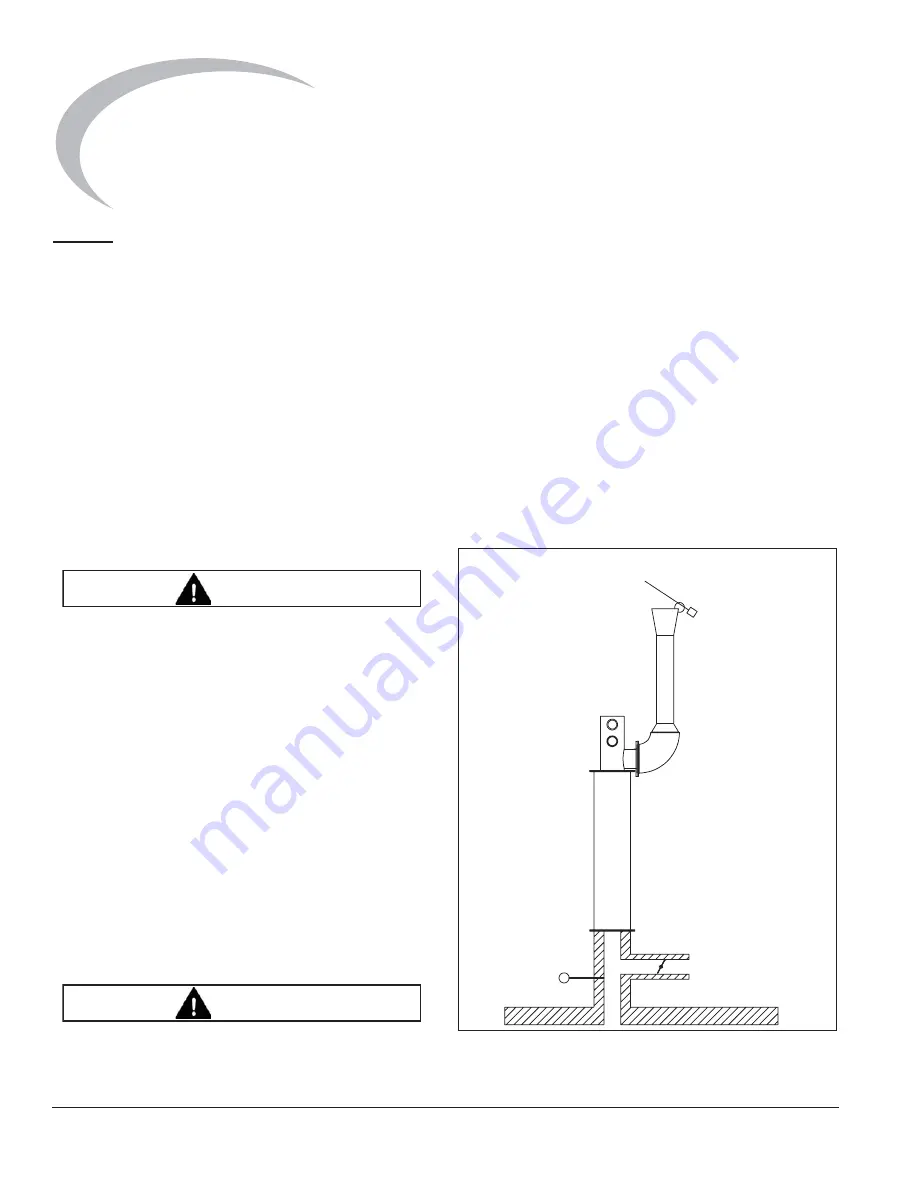

If the recuperator is to be used on aluminum melting

furnaces where flux is used, special precautions must be

taken to protect the recuperator during the fluxing cycle.

When flux is being used, the exit of the eductor should be

closed off and a by-pass duct opened until the fluxing is

complete and no fluxing agents are present in the

exhaust. Closing the damper on the eductor will force the

eductor air back through the recuperator ensuring that no

contaminated exhaust gases enter the recuperator. See

Figure 3.1.

Figure 3.1.

CAUTION

CAUTION

Eductor d

am

per

to be closed

w

hen

f

luxin

g

Byp

a

ss d

am

per

to be open

w

hen

f

luxin

g

System Design

3