EBARA End Suction Centrifugal

3U / 3UB

Operating, Installation, and Maintenance

EBARA

Fluid Handling

www.pumpsebara.com

3

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

IMPORTANT SAFETY INSTRUCTIONS

Rules for Safe Installation and Operation

Installation

Contents

Section

Page

Safety Specifications and Installation

3

3U / 3UB Selection Chart

5

3U / 3UB Specifications

6

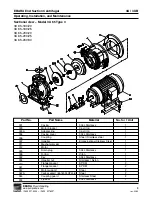

3U / 3UB Type 1 Sectional View and Parts List

7

3U(B) 65 Type 3 Sectional View and Parts List

8

Installation Instructions

9

Maintenance and Service

10

3U / 3UB Assembly – 3HP - 15HP

11

3U / 3UB Assembly – 20HP - 30HP

12

Troubleshooting Checklist and Maintenance Information

13

1.

Read these rules and instructions carefully. Failure to follow them could cause serious bodily injury and/or property damage.

2.

Check your local codes before installing. You must comply with their rules

3.

For maximum safety, this product should be connected to a grounded circuit equipped with a ground fault interrupter device.

4.

Before installing this product, have the electrical circuit checked by an electrician to make sure it is properly grounded.

5.

Before installing or servicing your pump, BE CERTAIN pump power source is disconnected.

6.

Make sure the line voltage and frequency of the electrical current supply agrees with the motor wiring. If motor is dual voltage

type, BE SURE it is wired correctly for your power supply.

7.

Complete pump and piping system MUST be protected against below freezing temperature. Failure to do so could cause severe

damage and voids the Warranty.

8.

Avoid system pressures that may exceed one and a half times the operating point selected from the pump performance curve.

9.

Do not run your pump dry. If it is, there will be damage to the pump seal.

PACKAGE CONTENTS

1.

Be sure all parts have been furnished and that nothing has been damaged in shipment.

2.

The catalog lists all parts included with package. A packing list packed with pump, also lists contents.

3.

OPEN PACKAGES AND MAKE THIS CHECK BEFORE GOING ON JOB.

PIPING – Pipes must line up and not be forced into position by unions. Piping should be independently supported near the

pump so that no strain will be placed on the pump casing. Where any noise is objectionable, pump should be insulated from

the piping with rubber connections. Always keep pipe size as large as possible and use a minimum of fittings to reduce

friction losses.

SUCTION PIPING – Suction pipe should be direct and as short as possible. It should be at least one size larger than suction

inlet tapping and should have a minimum of elbows and fittings (5 to 6 pipe diameters of straight pipe before inlet is recommended).

The piping should be laid out so that it slopes upward to pump without dips or high points so that air pockets are eliminated.

The highest point in the suction piping should be the pump inlet except where liquid flows to the pump inlet under pressure.

The suction pipe must be tight and free of air leaks or pump will not operate properly.

WARNING