Technical Data

TD534-0501002U

Instructions for the Installation,

Operation and Maintenance

of W-SLC-7.2

Effective January 2013

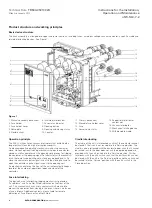

Inspection of vacuum interrupter

During routine inspection, check visually whether the external surface

of vacuum interrupter is clean. If there is dirt and other items present

then clean the bottles.

Inspection of contact’s wear-out

The contactor's vacuum contacts have a very long electrical life.

Usually, it only needs to be replaced after 300,000 operations.

A new contactor’s over-travel is 2mm. With the contact wear the

over-travel decreases. If contact wear is excessive a replacement

Vacuum interrupter can be installed into the contactor, It is

recommended that all 3 vacuum interrupters are replaced at the

same time. Check with the SL Contactor Operating Manual

ALL OPERATIONS AND MAINTENANCE WORK FOR THE W-SLC SHALL BE

CONDUCTED ON THE CONDITION THAT THE PRIMARY CIRCUIT IS NOT

LIVE. ONCE THE DEVICE IS POWERED ON, IT CAN CAUSE DANGER SUCH

AS ELECTRICAL SHOCK OR FIRE. USE PROPER VOLTAGE TRANSFORMERS

OR VOLTMETERS TO TEST VOLTAGE, IN ORDER TO ENSURE THAT THE

DEVICE IS NOT LIVE.

DANGER

WARNING

Maintenance

The W-SLC operates on certain conditions. Its maintenance period

depends on different factors such as surrounding environment and

operating cycles. Only experienced maintenance staff should be

permitted to conduct maintenance or inspection of the unit.

Usually, the device should get a complete inspection and check

every 50,000 operations or once a year, whichever occurs first.

The W-SLC must be stored in a clean place away from dirt and other

contaminants. Vacuum cleaners or blowers should be used to

remove dirt from the W-SLC.

Check for any loose connections for overheating or discoloration.

Check whether the insulation is damaged due to high temperature.

When checking fastening pieces, the screw torque should not be too

high as this could strip the threads. Hold each wire and pull

moderately, to check whether the wiring terminals are fastened.

HIGH VOLTAGE TESTING DANGER. PAY ATTENTION TO SAFETY!

Keep the contactor in open status, conduct the power frequency

withstand voltage test at 20kV maintain 1min across the open gap,

phenomena such as break down and discharging is not allowed.

Inspection of mechanisms

First, make visual inspection for any loose accessories and parts

including nuts and bolts. Then, inspect the W-SLC for any worn out

or damaged parts. Rack the W-SLC in and out several times, to

ensure smooth operation. All the parts which need lubrication are

lubricated before shipping. However if the lubricants have

degraded it may be essential to lubricate the parts during annual

inspection.

Usage of fuses

Before putting into use, check the fuse appearance for completeness,

wellness, cleanness and correct mounting direction. The striker pin

should be facing the front of the unit.

An interlocking tripping mechanism is fitted within the fuse holder

cover. When only one phase fuse blows, it will cause the contactor

to open. Similarly, if one phase fuse is not installed, the interlock

mechanism will prevent the contactor from closing.

In the event that the W-SLC experiences a 3 phase fault it may be

that only one fuse will blow due to the difference in actuation times

of each fuse and that the contactor will open when a single fuse is

blown. In this case even though the two remaining fuses appear to

be in good working order, the three fuses should all be replaced

together, due to overcurrent in the remaining fuses may have

permanently altered the tripping characteristics of the remaining

fuses.

Replacement of fuses

After the W-SLC fuse operates or goes through short circuit fault

current, the fuse should be replaced, to make sure that the unit

can work properly. All three phase fuses should be replaced at the

same time, unless there is enough evidence indicating that fault

current has not gone through a certain phase fuse – in case of a

single phase fault. To replace the fuses, below procedures should

be followed:

1. Ensure that the W-SLC cradle is in Test’ position, the contactor

is in OFF status. Remove the cradle from the panel and put it

into the transfer cart;

2. Use an inner hexagon spanner to remove the screws which

fasten movable fuse holder cover, see Figure 7;

8

EATON CORPORATION

www.eaton.com

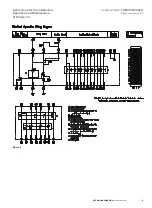

4. Troubleshooting:

NO.

Phenomenon

Causes

1

2

Not able to close

Cradle not able to be racked in/out

1. The contactor is already in closed status

2. The cradle is not fully into the fully connected or test positions

3. The firing pin in the fuse is already ejected out

4. Secondary circuit of the panel is not correct

1. The contactor is closed

2. Cradle racking handle is not fully engaged

3. Check that the shoot bolts on both sides of the front of the cradle. Make sure they are correctly

engaged in the side of the panel. If the shoot bolts are not engaged correctly then the racking

handle will be locked and unable to turn.

4. The circuit earth switch is in the ON position will prevent the cradle from being racked in.

Note:

Please check based on above causes. Contact the manufacturer if problems still exist.