EATON Vickers

Single, Double, Triple and Thru-drive Pumps Overhaul Service Manual V-PUVN-TS001-E October 2002

11

Section IV —

Installation and Operating

Instructions (cont.)

C. Shaft Rotation

General Data

Oil in a hydraulic system

performs the dual function of

lubrication and transmission of

power. It constitutes a vital

factor in a hydraulic system and

careful selection of it should be

made with the assistance of a

reputable supplier. Proper

selection of oil assures

satisfactory life and operation

of system components with

particular emphasis on

hydraulic pumps. Any oil

selected for use with pumps is

acceptable for use with valves

or motors.

See the Series 30 VMQ

product catalog for hydraulic

fluid guidelines.

Where special considerations

indicate a need to depart from

the recommended oils or

operating conditions, see your

Eaton representative.

Cleanliness

Clean fluid is the best

insurance for long service life.

Eaton recommends a fluid

cleanliness of ISO 18/16/13 or

better. To insure your hydraulic

system is clean, perform the

following steps.

1.

Clean (flush) entire new

system to remove paint, metal

chips, welding shot, etc.

2.

Filter each change of oil to

prevent introduction of

contaminants into the system.

3.

Provide continuous oil

filtration to remove sludge and

products of wear and corrosion

generated during the life of the

system.

4.

Provide continuous

protection of system from

entry of airborne

contamination, by sealing the

system and/or by proper

filtration of the air.

5.

Proper oil filling and

servicing of filters, breathers,

reservoirs, etc., cannot be

overemphasized.

6.

Good system and reservoir

design will insure that aeration

of the oil is kept to a minimum.

CAUTION

Pump shafts are

designed to be

installed in

couplings with a slip fit or very

light press. Pounding the

coupling on the shaft can ruin

the bearings. Shaft tolerances

are shown on the pump

installation drawings.

2. Indirect Drive.

Indirect drive

is not recommended for these

pumps.

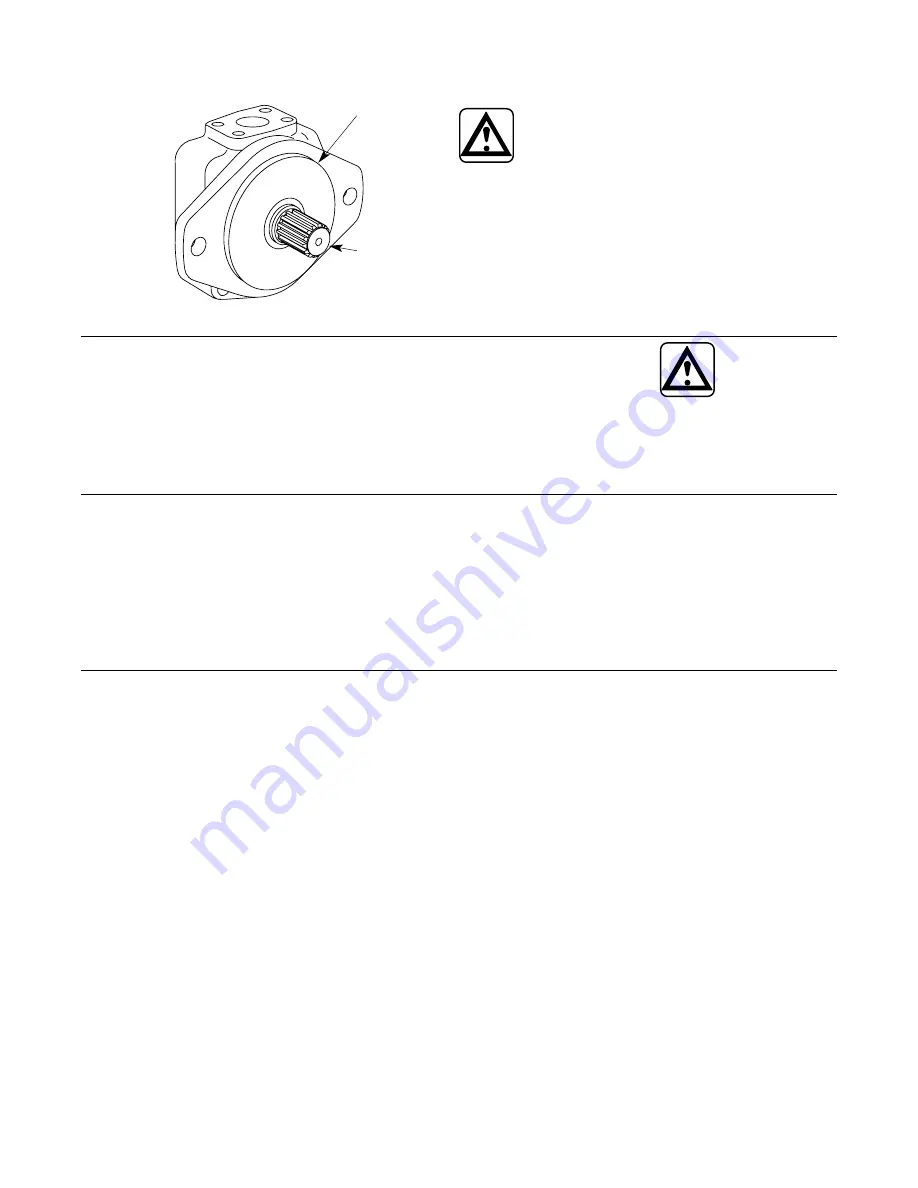

Figure 7.

Pilot Diameter

Pilot Diameter

Shaft

NOTE

Pumps are normally

assembled for right hand

(clockwise) rotation as viewed

from the shaft end. A pump

made for left hand rotation is

identified by an “L” in the

model code. (See Table 1)

NOTE

If it is desired to reverse the

direction of drive rotation, it is

necessary to disassemble the

pump and reverse the location

of the cartridge cam ring and

wafer plates. (See Section VI,

Part C)

CAUTION

Never drive a

pump in the wrong

direction of

rotation. Seizure may result,

necessitating extensive

repairs.

D. Piping and Tubing

1.

All pipes and tubing must be

thoroughly cleaned before

installation. Recommended

methods of cleaning are

sandblasting and wirebrushing.

2.

To minimize flow resistance

and the possibility of leakage,

use only as many fittings and

connections as necessary for

proper installation.

3.

The number of bends in

tubing should be kept to a

minimum to prevent excessive

turbulence and friction of oil

flow. Tubing must not be bent

too sharply. The recommended

radius for bends is three times

the inside diameter of the

tube.

E. Hydraulic Fluid Recommendations